Train Stopping: BHP Derails Runaway Locomotive From 800 Miles Away

06 Noviembre 2018 - 12:13AM

Noticias Dow Jones

By Rhiannon Hoyle

SYDNEY--It sounds like a plot from a movie: a train carrying

tons of cargo barreling out of control and a mission to stop

it.

But for BHP Billiton Ltd. it was real life, as four locomotives

and 268 loaded wagons ran loose for more than 50 miles without a

driver.

Monday's journey was meant to be a regular rail movement from

BHP's iron-ore mines in Western Australia's Pilbara region, where

temperatures can top 100 degrees Fahrenheit in summer and vast

distances separate communities. But when the driver disembarked to

inspect one of the wagons loaded with ore, the train wasn't

properly secured and began to roll away.

It took off, and traveled about 57 miles in 50 minutes.

With the train out of control and headed toward Port Hedland, on

Australia's west coast, operators some 800 miles away in Perth took

action. Using remote sensors to switch points at an isolated part

of the Outback, they forcibly derailed the train in the desert

without anyone being hurt.

In a statement, BHP said it was working to recover the rogue

train from the desert some 75 miles from the coast--action that

could take up to a week.

Still, the derailment disrupted the company's operations and led

to a 2.3% jump in iron-ore prices Monday as traders bet on reduced

supply of a key ingredient in steelmaking. BHP suspended all of its

rail operations while the circumstances that led to the train

running loose are investigated by the Australian Transport Safety

Bureau.

The derailment comes amid heightened scrutiny of BHP's safety

record since a deadly spill at its Samarco iron-ore venture with

Vale SA in Brazil in late 2015. The disaster led Brazilian

prosecutors to file a claim against BHP and its partner for several

billions of dollars, among other lawsuits. BHP and Vale have agreed

to settle some claims.

The Pilbara region accounts for roughly half of all iron ore

traded by sea, with most of the cargoes feeding China's

industrialization. BHP is the region's second-largest producer of

the commodity, after Rio Tinto PLC.

Global miners have been spending heavily to remove the human

factor from a complex supply chain spanning thousands of miles

across continents, part of a program to save billions of dollars

and cushion profits against swings in commodity prices. That

spending has included setting up remote operations centers far from

mines where staff can monitor everything from trucks, drills and

conveyor belts on giant screens and control them at the touch of a

button.

For some companies, automated trains are the next big

innovation. Rio Tinto PLC last month said it is using more

automated trains in the Pilbara and expects to have all of its

iron-ore trains operating without a driver on board by the end of

this year.

BHP is taking a more patient approach to the technology, as it

worries about congestion on the more than 800-mile rail network

that it operates in the Pilbara. While it is using lasers to

automate the track, it hasn't given a timeline on how long it will

be before it uses driverless trains.

Write to Rhiannon Hoyle at rhiannon.hoyle@wsj.com

(END) Dow Jones Newswires

November 06, 2018 00:58 ET (05:58 GMT)

Copyright (c) 2018 Dow Jones & Company, Inc.

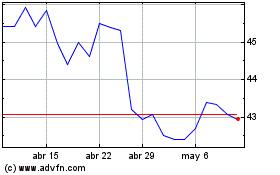

BHP (ASX:BHP)

Gráfica de Acción Histórica

De Mar 2024 a Abr 2024

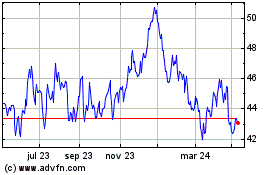

BHP (ASX:BHP)

Gráfica de Acción Histórica

De Abr 2023 a Abr 2024