By Peter Loftus

Manufacturers are racing to boost production of the medical

ventilators required to save the lives of many critically ill

coronavirus patients, but there still may not be enough of the

crucial machines if cases surge, industry officials say.

Medtronic PLC, Philips NV, Draegerwerk AG and Getinge AB, among

the biggest suppliers of medical ventilators and related

respiratory equipment, said they are working to meet increased

global demand, including in the U.S.

Even companies that don't make medical devices may chip in.

General Motors Co. and Ford Motor Co. are exploring the possibility

of making ventilators, spokespeople for the companies said

Thursday. The auto makers have temporarily suspended vehicle

production in North America until at least March 30.

The added capacity may eventually help ease the crunch, but it

isn't coming fast enough to keep up with mounting demand and may

not be sufficient if cases surge, industry officials and health

experts say.

"The actual available inventory on the shelf is gone," said

Chris Brooks, chief strategy officer at Ventec Life Systems, of

Bothell, Wash. "There's definitely more demand than there is supply

today. We're doing everything we can to ramp up supply."

As many as 810,000 U.S. coronavirus patients could need

ventilators by the end of May, if cases were to double every six

days, according to Neil Carpenter, vice president of strategic

planning at health-care consultancy Array Advisors.

Yet the Society of Critical Care Medicine estimated, in a report

released this week, that more than 200,000 mechanical ventilators

may be available in the U.S.

If more machines become available, there may not be enough

trained professionals to operate them, said Lewis Kaplan, the

society's president and professor of surgery at the Hospital of the

University of Pennsylvania.

The critical-care society estimates that the number of trained

physicians, respiratory therapists and nurses would limit the

maximum number of ventilated patients to about 135,000.

Hamilton Medical AG, a Swiss company with operations in Nevada,

has received hundreds of orders in recent weeks, including a steep

increase in the U.S. The orders, a spokeswoman said, are "more than

we can currently provide."

To meet higher demand in Asia and Europe as well as the U.S.,

Hamilton is hiring new staff and expanding to weekend work, among

other steps. The company expects to increase production in

Switzerland to 400 ventilators a week, up from about 200

currently.

Medtronic said Wednesday it has boosted ventilator production by

more than 40% and is on track to more than double capacity to meet

"significantly increased" demand. The company said it would more

than double the 250-person workforce at its Galway, Ireland, plant

that makes its Puritan line of ventilators.

Yet hospitals face weeks of waiting for additional machines,

because the average turnaround time for new orders is about eight

weeks, said Soumi Saha, senior director of advocacy at Premier

Inc., which negotiates supply contracts for U.S. hospitals.

Premier is surveying U.S. hospitals to gauge how many more

patients hospitals can manage before they will need more

ventilators, Ms. Saha said.

Ventilators are machines -- many about the size of a desktop

printer -- that aid breathing. Critically-ill coronavirus patients,

like those with pneumonia in intensive-care units who are having

trouble breathing, need the assistance to survive. The devices cost

anywhere from $5,000 to more than $30,000 apiece.

The ventilators are mainly in hospitals, though a federal

government stockpile also has the machines.

The stockpile, which is intended to fill supply gaps in

emergencies, has about 12,700 ventilators, Anthony Fauci, director

of the National Institute of Allergy and Infectious Diseases, told

CNN Sunday. The Department of Health and Human Services has ordered

more ventilators, a spokeswoman said.

Hospital officials hope that recent government bans on large

gatherings and other measures will mitigate the spread of the virus

in the U.S. and avert overwhelming the supply of ventilators. In

Italy, some hospitals either have no ventilators or not enough for

all patients who need them.

Other respiratory devices could be deployed in a pinch instead

of mechanical ventilators, said Eric Toner, senior scholar at the

Johns Hopkins Center for Health Security. One such device is a

BiPap, a machine connected to a mask that goes over a patient's

face and pushes air into the lungs. They are similar to CPAP

machines that people use at home for sleep apnea.

Top Democratic lawmakers pressed President Trump on Thursday to

use the Defense Production Act to force U.S. industry to make

ventilators and other medical supplies. Senate Minority Leader

Chuck Schumer (D., N.Y.) and House Speaker Nancy Pelosi (D.,

Calif.) have said President Trump should use his powers under the

act to ensure the availability of ventilators, as well as testing

kits, masks and beds.

"We must put more testing, more protective equipment and more

ventilators into the hands of our front-line workers immediately,"

said Mrs. Pelosi.

President Trump said on Wednesday he was invoking the act in

case he needed to use it in the future if matters worsen.

In a letter to Vice President Mike Pence, hospital, nursing,

pharmaceutical and insurer groups said the matter is urgent. They

urged the federal government to "expeditiously move to spur

massive, increased production, distribution, and access to gowns,

masks, gloves, testing kits, testing swabs, and respiratory

machines."

--Siobhan Hughes contributed to this article.

Write to Peter Loftus at peter.loftus@wsj.com

(END) Dow Jones Newswires

March 19, 2020 15:56 ET (19:56 GMT)

Copyright (c) 2020 Dow Jones & Company, Inc.

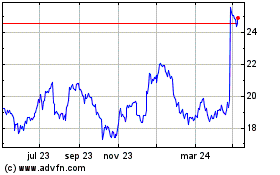

Koninklijke Philips NV (EU:PHIA)

Gráfica de Acción Histórica

De Mar 2024 a Abr 2024

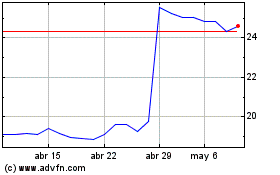

Koninklijke Philips NV (EU:PHIA)

Gráfica de Acción Histórica

De Abr 2023 a Abr 2024