UNITED

STATES

SECURITIES

AND EXCHANGE COMMISSION

Washington,

D.C. 20549

FORM

SD

Specialized

Disclosure Report

RALPH

LAUREN CORPORATION

(Exact

name of registrant as specified in its charter)

| Delaware |

001-13057 |

13-2622036 |

(State

or other jurisdiction

of

incorporation) |

(Commission

File Number) |

(I.R.S.

Employer

Identification

No.) |

| |

|

|

650

Madison Avenue, New York, NY 10022

(Address

of principal executive offices, including zip code)

Jane

Hamilton Nielsen

Chief

Operating Officer

(212)

318-7000

(Name

and telephone number, including area code, of the person

to contact in connection with this report)

Check the appropriate

box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

| ☒ |

Rule

13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2023. |

| ☐ |

Rule 13q-1 under the Securities Exchange Act (17 CFR 240.13q-1) for the

fiscal year ended _______. |

Section 1 – Conflict Minerals Disclosure

Item 1.01. Conflict Minerals Disclosure and Report

Ralph Lauren Corporation (the “Company”)

is a global leader in the design, marketing, and distribution of luxury lifestyle products, including apparel, footwear & accessories,

home, fragrances, hospitality and other licensed product categories. The Company does not directly manufacture products but rather contracts

for the manufacture of products. This disclosure relates to the following product categories (the “Covered Products”): apparel,

footwear & accessories, and home. The Covered Products include products: (a) that were manufactured by certain third parties that

affixed the Company’s brand, marks, logo or label to a generic product; and (b) for which we exerted sufficient influence over the

manufacture of the products such that we could be considered to have contracted for their manufacture. The Covered Products do not include

licensed product categories.

Unless the context indicates otherwise, the

terms “Company,” “we,” “us” and “our” refer to Ralph Lauren Corporation and its consolidated

subsidiaries.

Conflict Minerals Disclosure

This Specialized Disclosure Form (“Form

SD”) is filed pursuant to Rule 13p-1 promulgated under the Securities Exchange Act of 1934, as amended (collectively with the Form

SD, the “Conflict Minerals Rule”), for the period from January 1, 2023 to December 31, 2023 (the “Reporting Period”).

We contract to manufacture certain products in which columbite-tantalite (coltan), cassiterite, gold, and wolframite, or their derivatives,

tantalum, tin and tungsten (collectively, the “3TGs”), may be necessary to the functionality or production of those products.

The Company conducted a reasonable country

of origin inquiry (“RCOI”) to ascertain whether any 3TGs contained in our products originated in the Democratic Republic of

the Congo (“DRC”) or an adjoining country (collectively, the “Covered Countries”) as defined in Rule 13p-1 of

the Securities Exchange Act of 1934, as amended. The Conflict Minerals Report describes our RCOI and additional due diligence efforts

to determine the source and chain of custody of the 3TGs that may be necessary to the functionality or production of our Covered Products.

Item 1.02. Conflict Minerals Report

A copy of the Company’s Conflict Minerals

Report is provided as Exhibit 1.01 to this Form SD and is publicly available at http://investor.ralphlauren.com.

Section 3 – Exhibits

Item 3.01. Exhibits

Exhibit 1.01 – Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form SD

SIGNATURES

Pursuant to the

requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly

authorized undersigned.

| |

RALPH LAUREN CORPORATION |

|

| |

|

|

| Date: May 31, 2024 |

By: |

/s/ Jane Hamilton Nielsen |

|

| |

|

Name: Jane Hamilton Nielsen

Title:

Chief Operating Officer |

|

EXHIBIT 1.01

RALPH LAUREN CORPORATION

Conflict Minerals Report

For the Year Ended December 31, 2023

This Conflict Minerals Report of Ralph Lauren

Corporation (the “Company”) has been prepared pursuant to Rule 13p-1 promulgated under the Securities Exchange Act of 1934,

as amended (the “Conflict Minerals Rule”), for the reporting period January 1, 2023 to December 31, 2023 (the “Reporting

Period”). Unless the context indicates otherwise, the terms “Company,” “we,” “us” and “our”

refer to Ralph Lauren Corporation and its consolidated subsidiaries.

The Conflict Minerals Rule imposes certain

reporting obligations on public companies whose manufactured products contain conflict minerals that are necessary to the functionality

or production of their products. The term “conflict minerals” is defined by the Conflict Minerals Rule as: (a) cassiterite,

columbite-tantalite (coltan), gold, wolframite, and their derivatives, which are limited to tin, tantalum, and tungsten (collectively,

the “3TGs”); or (b) any other mineral or its derivatives determined by the Secretary of State to be financing conflict in

the Democratic Republic of Congo (“DRC”) or any adjoining country that shares an internationally recognized border with the

DRC (the Republic of the Congo, the Central African Republic, South Sudan, Rwanda, Uganda, Zambia, Burundi, Tanzania and Angola) (collectively

referred to as the “Covered Countries”).

The Company determined that we are subject

to the requirements of the Conflict Minerals Rule because we contract to manufacture certain products in which one or more of the 3TGs

may be necessary to the functionality or production of those products. As a result of this determination, the Company conducted a reasonable

country of origin inquiry (“RCOI”) to ascertain whether any of the 3TGs in its products originated from the Covered Countries

or from recycled or scrap sources. Based on the results of the RCOI and in accordance with the Conflict Minerals Rule, the Company then

performed due diligence on the source and chain of custody of the 3TGs.

Section 1. Company Overview

The Company is a global leader in the design,

marketing, and distribution of luxury lifestyle products, including apparel, footwear & accessories, home, fragrances, hospitality,

and other licensed product categories. We do not directly manufacture products but rather we contract for the manufacture of our products.

This report relates to the following product categories (the “Covered Products”): apparel, footwear & accessories, and

home. The Covered Products include products: (a) that were manufactured by certain third parties that affixed the Company’s brand,

marks, logo or label to a generic product; and (b) for which we exerted sufficient influence over the manufacture of the products such

that we could be considered to have contracted for their manufacture. The Covered Products do not include licensed product categories.

We have a global network of suppliers, vendors,

and factories (the “Supply Chain Participants”) and there are, generally, multiple tiers between the 3TG sources and our direct

Supply Chain Participants. Since we do not directly manufacture products but rather contract for the manufacture of the Covered Products,

we must rely on our Supply Chain Participants to provide information regarding the products they supply to us and the origin of any 3TGs

that are necessary to the functionality of those products. Due to the depth of our supply chain, we are far removed from the sources of

ore from which 3TGs are produced and the smelters/refiners that process those ores. The efforts undertaken to identify the countries of

origin of those ores reflect the Company’s circumstances and position in the supply chain as a “downstream” company

with no direct influence on smelters or refiners. Since we do not have a direct relationship with smelters and refiners of 3TGs, we do

not conduct or commission independent third party-audits of the smelters and refiners from which our independent Supply Chain Participants

source 3TGs. We rely upon industry initiatives, such as the Responsible Minerals Initiative (“RMI”) founded by the Responsible

Business Alliance (“RBA”) for independent third-party audit information.

We are opposed to human rights abuses such

as those occurring in the Covered Countries and are committed to the principles of ethical business practices, including the responsible

sourcing of 3TGs. We expect that our Supply Chain Participants share this commitment and require that they cooperate with us in the compliance

of the Conflict Minerals Rule.

Our expectations with respect to sourcing 3TGs

reflect our continuing commitment to: identify product manufactured for us that contain 3TGs; engage with our Supply Chain Participants

to identify the origin of those 3TGs; and deliver products to our consumers that are manufactured in a responsible and ethical manner.

As we enter into new contractual arrangements with our Supply Chain Participants, or our contracts renew, we include provisions requiring

them to represent that they do not source 3TGs from non-certified mines in the Covered Countries, and that they will identify, document

and disclose to us, the source origins of any 3TGs utilized in their supply chain.

Section 2. Reasonable Country of Origin

Inquiry (“RCOI”)

Due to the complexity of our supply chain and

the breadth of our product offerings, we developed a risk-based approach that focused on Supply Chain Participants who were: (a) direct

finished goods vendors, and (b) suppliers of raw materials and components that we believed were likely to supply us with products containing

any of the 3TGs (such as hardware or metal components suppliers). As a result of our review, we determined that during the Reporting Period,

we contracted to manufacture certain Covered Products containing 3TGs which are necessary to the functionality or production of those

products. Based on this determination, we then conducted an RCOI to ascertain whether any 3TGs in the Covered Products originated in the

Covered Countries.

To determine the origin of the 3TGs in the

Covered Products, we retained an independent third-party service provider (the “Service Provider”), to assist us in reviewing

our supply chain. Utilizing the Service Provider’s web-based software as a service tool, the Company requested its Supply Chain

Participants to complete a survey (the “Conflict Minerals Survey”). The Conflict Minerals Survey was designed using the RMI’s

Conflict Minerals Reporting Template (“CMRT”). The Service Provider’s system allowed suppliers to complete and upload

the CMRT directly into the system, and it provided the users with the ability to assess and manage information, as well as track and manage

communications with suppliers within the system. In certain limited instances, Supply Chain Participants were also contacted directly

via email communication. The Conflict Minerals Survey was accompanied by an introductory message reiterating, to our Supply Chain Participants,

our commitment to the responsible sourcing of 3TGs, and our expectations that our Supply Chain Participants share this commitment and

cooperate with our compliance efforts.

The use of the CMRT allowed for some elimination

of “out of scope” suppliers. The CMRT also allowed us to collect the following information from each of our Supply Chain Participants:

| i. | the types of raw materials, product components or Covered Products such Supply Chain Participant provided

to the Company during the Reporting Period; |

| ii. | information regarding the source or origin of any 3TGs, including the names and locations of smelters

and refiners or source of 3TGs supplied to the Company; |

| iii. | whether any 3TGs supplied to the Company came from recycled or scrap sources; and |

| iv. | other additional information related to such Supply Chain Participant’s sourcing and compliance

activities. |

Our Supply Chain Participants were required

to submit completed CMRTs through the Service Provider’s system. In addition to communicating with the Supply Chain Participants

via the Service Provider’s platform, the escalation process for non-responsive Supply Chain Participants also included at least

three additional follow-up emails, telephone calls and direct communications, as necessary.

The Service Provider’s software tool

provided the ability to conduct automated data validation to review each completed CMRT for completeness, reasonableness, and consistency

of answers. Upon receipt, all submitted forms were reviewed and classified as either “valid” or “invalid.” All

Supply Chain Participants who submitted incomplete or inconsistent answers were classified as “invalid” and were contacted

for clarification on specific responses or to request the resubmission of a valid CMRT. Additionally, the Service Provider’s platform

provides Supply Chain Participants access to education and training resources to guide Supply Chain Participants on navigating through

the CMRT, and best practices for corrective action methods and ways to improve their own internal programs. All communications were monitored

and tracked in the Service Provider’s Conflict Minerals portal for future reporting and transparency.

Based on the results of the RCOI and in accordance

with the Conflict Minerals Rule, the Company then performed due diligence on the source and chain of custody of the 3TGs.

Section 3. Due Diligence Measures

Design

We based our due diligence measures, in all

material respects, on the framework set forth in the Organisation for Economic Co-Operation and Development (“OECD”) Due Diligence

Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High Risk Areas: Third Edition, including the supplements

on tin, tantalum, tungsten and gold (“OECD Guidance”). The OECD Guidance was written for both upstream and downstream companies

in the supply chain. Since the Company is a “downstream” company, with no direct relationship or influence on smelters or

refiners of 3TGs, our due diligence practices were tailored accordingly. We also consider the requirements of the European Union Conflicts

Minerals Rule with respect to due diligence efforts.

Step 1: Establish Strong Company Management Systems

The Company has developed management systems regarding the Conflict

Minerals Rule. These systems include the following elements:

| · | Conflict Minerals Policy: The Company has adopted a Conflict Minerals Policy which is available

at https://corporate.ralphlauren.com/reports-and-policies |

| · | Internal Team: The Company has established an

internal team responsible for managing the due diligence process to comply with the Conflict Minerals Rule. This team includes representatives

from the following departments at the Company: (i) Global Citizenship, Worker Well- Being; (ii) Global Manufacturing and Sourcing; (iii)

Global Quality Assurance & Testing; and (iv) Legal. As previously noted, the Company also utilizes a Service Provider, to complement

our internal Conflict Minerals team. The Service Provider assists with collecting and evaluating supply chain information regarding 3TGs,

communicating with Supply Chain Participants, and developing and implementing due diligence measures. The Company leverages the Services

Provider’s dedicated multi-lingual program specialists who are trained in conflict minerals compliance and the intricacies of the

CMRT and conflict minerals reporting; |

| · | Control Systems: The Company has established

a control system which documents its due diligence activities, including findings and communications, within our supply chain. Utilizing

the Service Provider’s web-based system, we communicated the Company’s expectations regarding compliance with the Conflict

Minerals Rule, to our Supply Chain Participants, and followed-up with our Supply Chain Participants via e-mail and telephone conversations.

All these activities are documented and retained in the Service Provider’s database; |

| · | Supplier Engagement: As we enter into new or

renew our existing contractual arrangements with our Supply Chain Participants, we include provisions requiring them to represent that

they do not source 3TGs from non-certified mines in the Covered Countries, and that they will identify, document and disclose to us, the

source origins of any 3TGs utilized in their supply chain. The Company provided each of its Supply Chain Participants with a CMRT, using

the Service Provider’s web-based tool. The Service Provider reviewed each survey and conducted due diligence by following-up on

each Supply Chain Participant’s responses in their Conflict Minerals Survey, as applicable. To further strengthen communication

and engagement with Supply Chain Participants, we have also utilized the Service Provider’s learning management systems, and provided

all Supply Chain Participants with access to training material and courses which focus on responsible sourcing. For non-English speaking

suppliers, Supply Chain Participants are provided access to the Service Provider’s multilingual help desk support and other multilingual

resources to provide guidance and educational opportunities related to properly filing the CMRT; |

| · | Grievance Mechanism: The Company has implemented

a mechanism that provides for confidential reporting of suspected violations or concerns through the Company’s RL Hotline,

a reporting service that is maintained by an independent third party. Violations or grievances at the industry level may also be reported

to the RMI directly, via the RMI Minerals Grievance Platform, accessible at: https://mineralsgrievanceplatform.org/;

and |

| · | Maintain Records: The Company has implemented

a document retention policy through the Service Provider’s system which will retain Conflict Minerals-related documents, including

the Supply Chain Participants’ responses to Conflict Minerals Surveys and sources identified, for a period of five (5) years. The

Service Provider’s database can be audited by internal or external parties. |

Step 2: Supply Chain Risk Identification

and Assessment

Areas of risks are identified in the Service

Provider’s system based on criteria established for the Supply Chain Participants’ responses. These risks are addressed by

the Service Provider and members of the Company’s internal Conflict Minerals team by contacting the Supply Chain Participant, gathering

additional pertinent data (as necessary) and performing an assessment of such Supply Chain Participant’s Conflict Minerals status.

As previously noted, our Supply Chain Participants

consist of a global network of suppliers, vendors, and factories. As such, completed CMRTs from each of our Supply Chain Participants

were comprehensive and, in most cases, included all facilities in such participant’s network, not just the particular facility that

produced the Company’s Covered Products. As a result, because of the nature of our Supply Chain Participants’ global network

of factories and facilities, this report may include more facilities than those that actually processed the 3TGs present in the Company’s

Covered Products.

To the extent that specific smelters or refiners

of 3TGs were identified by our Supply Chain Participants, the Service Provider compared the responses from the completed CMRTs with known

processing facilities in the RMI list of active participants in the RMI Responsible Minerals Assurance Process (“RMAP”) Gold

Standard, Tin and Tantalum Standard, Tungsten Standard, as applicable, as well as the London Bullion Market Association Responsible Gold

Audit Program and the Responsible Jewellery Council Chain of Custody Certification Program. Each identified facility was compared to the

RMI list of smelters and refiners to ensure that facilities met the recognized definition of a 3TG processing facility. If a Supply Chain

Participant indicated that the facility was certified as “Conflict-Free,” the Service Provider confirmed that the name of

such facility was certified through the RMAP process and has undergone a successful audit against a standard in conformance with the OECD

Guidance, such as the RMAP.

Once a facility was found to meet the RMI definition

of a 3TG smelter or refiner, such facility was assessed for risk, based on the presence of red flag indicators including, but not limited

to, those listed in the OECD Guidance, such as:

| · | Geographic location in countries subject to sanctions, such as Russia; |

| · | Business dealings with or links to individuals or entities subject to sanctions; |

| · | Geographic proximity to conflict-affected and high-risk areas, including the DRC and Covered Countries; |

| · | Credible evidence of unethical or sourcing of Conflict Minerals; |

| · | Known mineral source country of origin; and |

| · | Peer Assessments conducted by credible third-party sources. |

Additionally, the Supply Chain Participants

were evaluated on whether they had implemented a program that incorporated the responsible sourcing due diligence measures, including

conflict minerals practices and policies, as recommended by the OECD. Assessing whether a Supply Chain Participant’s program meets

the OECD Guidance assists us in identifying risk in our supply chain and in making key risk mitigation decisions as our Conflict Minerals

compliance program evolves.

Step 3: Design and Implement a Strategy

to Respond to Risks

The Company’s risk management plan to

respond to any situations which might arise involving Conflict Minerals includes carrying out the due diligence described in this Report,

understanding the products impacted by any supplied materials identified as containing 3TGs, understanding the extent of the Company’s

reliance on such materials, undertaking additional due diligence and risk mitigation to respond to identified risks, and communicating

to our Supply Chain Participants that any 3TGs should be sourced responsibly.

Feedback on CMRT submissions are provided directly

to Supply Chain Participants, and multilingual educational resources regarding corrective action methods and improvements to supplier

programs and processes are available at no expense on the Service Provider’s platform. In accordance with OECD Guidance, risk mitigation

will depend on the Supply Chain Participant’s specific program, including such participant’s due diligence measures, and corrective

actions.

Step 4: Independent Third Party Private Sector Audit

We are not required to obtain an independent

private sector audit (“IPSA”). If an IPSA is required in the future, we will outline the results of any required audit. We

do not have a direct relationship with any 3TG smelters or refiners and do not perform or direct audits of these entities within our supply

chain. Instead, we rely on third-party audits of smelters and refiners conducted as part of the RMI RMAP Audit Program, which uses independent

private sector auditors to audit the source, including the mines of origin, and the chain of custody of the conflict minerals used by

smelters and refiners that agree to participate in the program. The Service Provider also directly contacts smelters and refiners that

are not currently enrolled in the RMAP to encourage their participation and gather information regarding each facilities’ sourcing

practices.

Step 5: Report on Supply Chain Due Diligence

With the preparation and release of this Report,

we have published a report of our due diligence measures with respect to the sourcing of 3TGs. A copy of this report is available at

http://investor.ralphlauren.com. We have also publicly filed our Form SD and Conflict Minerals

Report with the Securities and Exchange Commission (the “SEC”).

Section 4. Due Diligence Findings

Based on the survey responses received from

our Supply Chain Participants, we believe that gold and tin are, or may be, necessary to the functionality or production of: (1) products

that our Company contracts to be manufactured, including, but not limited to apparel, and metal components such as zippers, trims, rivets,

buttons, and buckles, and (2) accessories, such as, watches and fine jewelry.

As previously noted, the Company does not have

a direct relationship with smelters or refiners of 3TGs, and as a result, we must rely on our suppliers to provide us with smelter, refiner

and country of origin data.

Based on our RCOI, we believe that the facilities

that were used by our Supply Chain Participants to process the 3TGs that may be contained in our Covered Products included, but may not

be limited to, the smelters and refiners listed in the chart attached hereto as Schedule A and sourced from the countries of origin listed

in Schedule B below. As previously noted, many of the CMRTs collected were provided at the Supply Chain Participant’s company or

division level and therefore may include more facilities than those that actually processed the 3TGs present in the Company’s Covered

Products.

Our Supply Chain Participants identified a

total of 236 smelters and refiners which appear on the list maintained by the RMI. Of these, approximately 218 (approximately 92%) were

identified as “conformant” with RMAP.

Section 5. Steps to be Taken to Mitigate

Risk

We intend to take the following steps to improve our due diligence

measures and/or endeavor to mitigate risks:

| i. | continue to communicate with our Supply Chain Participants regarding our expectations and requirements

for compliance; |

| ii. | continue to refine the RCOI process and procedures in

an effort to increase the Conflict Minerals Survey response rate and improve the content of our Supply Chain Participants’ responses

to the Conflict Minerals Survey; |

| iii. | continue to monitor information regarding global traceability

of raw materials in our products and continue to assess the use and source of 3TGs in our supply chain; |

| iv. | engage with our Supply Chain Participants to conduct further due diligence on smelters in high risk

countries; |

| v. | continue to raise awareness of our Supply Chain Participants

by directing them to information and training resources regarding responsible sourcing of 3TGs and encouraging identified smelters and

refiners to become audited in accordance with OECD Guidance; |

| vi. | continue to identify additional available resources

to evaluate risks, including: comprehensive smelter and refinery databases with detailed listings and audit status, credible media reports

relating to 3TG sourcing, and open source regulatory databases for comparing facilities against government watch and denied parties lists; |

| vii. | continue to monitor global legislative and regulatory

developments and industry trends related to responsible sourcing focusing on human rights due diligence, transparency and risk mitigation;

and |

| viii. | continue to participate in industry-based efforts, such

as the working group on Conflict Minerals organized by the American Apparel & Footwear Association, and relevant trade associations,

such as the National Retail Federation and the United States Fashion Industry Association, to encourage further improvement and reliability

in 3TG traceability programs, encourage responsible sourcing of 3TGs and to define and implement best practices. |

SPECIAL NOTE REGARDING FORWARD LOOKING STATEMENTS

Certain statements in this report or incorporated

by reference into this report, in future filings by us with the SEC, in our press releases, and in oral statements made from time to time

by us or on our behalf constitute “forward-looking statements” within the meaning of the Private Securities Litigation Reform

Act of 1995. Forward-looking statements are based on current expectations and are indicated by words or phrases such as “anticipate,”

“outlook,” “estimate,” “ensure,” “commit,” “expect,” “project,”

“believe,” “envision,” “goal,” “target,” “can”, “will” and similar

words or phrases. These forward-looking statements involve known and unknown risks, uncertainties, and other factors which may cause actual

results, performance, or achievements to be materially different from the future results, performance, or achievements expressed in or

implied by such forward-looking statements. We undertake no obligation to publicly update or revise any forward-looking statements, whether

as a result of new information, future events, or otherwise.

Schedule A

| METAL |

SMELTER OR REFINER NAME |

SOR ID |

| Gold |

Shandong Zhaojin Gold & Silver Refinery Co., Ltd. |

CID001622 |

| Gold |

Metalor Technologies (Hong Kong) Ltd. |

CID001149 |

| Gold |

Chimet S.p.A. |

CID000233 |

| Gold |

Safimet S.p.A |

CID002973 |

| Gold |

Argor-Heraeus S.A. |

CID000077 |

| Gold |

Boliden AB |

CID000157 |

| Gold |

MKS PAMP SA |

CID001352 |

| Gold |

Rand Refinery (Pty) Ltd. |

CID001512 |

| Gold |

Valcambi S.A. |

CID002003 |

| Gold |

Degussa Sonne / Mond Goldhandel GmbH |

CID002867 |

| Gold |

Metalor Technologies S.A. |

CID001153 |

| Gold |

Advanced Chemical Company |

CID000015 |

| Gold |

Aida Chemical Industries Co., Ltd. |

CID000019 |

| Gold |

Agosi AG |

CID000035 |

| Gold |

Almalyk Mining and Metallurgical Complex (AMMC) |

CID000041 |

| Gold |

AngloGold Ashanti Corrego do Sitio Mineracao |

CID000058 |

| Gold |

Asahi Pretec Corp. |

CID000082 |

| Gold |

Asaka Riken Co., Ltd. |

CID000090 |

| Gold |

Aurubis AG |

CID000113 |

| Gold |

Bangko Sentral ng Pilipinas (Central Bank of the Philippines) |

CID000128 |

| Gold |

C. Hafner GmbH + Co. KG |

CID000176 |

| Gold |

CCR Refinery - Glencore Canada Corporation |

CID000185 |

| Gold |

Cendres + Metaux S.A. |

CID000189 |

| Gold |

Chugai Mining |

CID000264 |

| Gold |

DSC (Do Sung Corporation) |

CID000359 |

| Gold |

Dowa |

CID000401 |

| Gold |

Eco-System Recycling Co., Ltd. East Plant |

CID000425 |

| Gold |

LT Metal Ltd. |

CID000689 |

| Gold |

Heimerle + Meule GmbH |

CID000694 |

| Gold |

Heraeus Metals Hong Kong Ltd. |

CID000707 |

| Gold |

Heraeus Germany GmbH Co. KG |

CID000711 |

| Gold |

Inner Mongolia Qiankun Gold and Silver Refinery Share Co., Ltd. |

CID000801 |

| Gold |

Ishifuku Metal Industry Co., Ltd. |

CID000807 |

| Gold |

Istanbul Gold Refinery |

CID000814 |

| Gold |

Japan Mint |

CID000823 |

| Gold |

Jiangxi Copper Co., Ltd. |

CID000855 |

| Gold |

Asahi Refining USA Inc. |

CID000920 |

| Gold |

Asahi Refining Canada Ltd. |

CID000924 |

| Gold |

JX Nippon Mining & Metals Co., Ltd. |

CID000937 |

| Gold |

Kazzinc |

CID000957 |

| Gold |

Kennecott Utah Copper LLC |

CID000969 |

| Gold |

Kojima Chemicals Co., Ltd. |

CID000981 |

| Gold |

LS-NIKKO Copper Inc. |

CID001078 |

| Gold |

Materion |

CID001113 |

| Gold |

Matsuda Sangyo Co., Ltd. |

CID001119 |

| Gold |

Metalor Technologies (Suzhou) Ltd. |

CID001147 |

| Gold |

Metalor Technologies (Singapore) Pte., Ltd. |

CID001152 |

| Gold |

Metalor USA Refining Corporation |

CID001157 |

| Gold |

Metalurgica Met-Mex Penoles S.A. De C.V. |

CID001161 |

| Gold |

Mitsubishi Materials Corporation |

CID001188 |

| Gold |

Mitsui Mining and Smelting Co., Ltd. |

CID001193 |

| Gold |

Nadir Metal Rafineri San. Ve Tic. A.S. |

CID001220 |

| Gold |

Navoi Mining and Metallurgical Combinat |

CID001236 |

| Gold |

Nihon Material Co., Ltd. |

CID001259 |

| Gold |

Ohura Precious Metal Industry Co., Ltd. |

CID001325 |

| Gold |

PT Aneka Tambang (Persero) Tbk |

CID001397 |

| Gold |

PX Precinox S.A. |

CID001498 |

| Gold |

Royal Canadian Mint |

CID001534 |

| Gold |

Samduck Precious Metals |

CID001555 |

| Gold |

SEMPSA Joyeria Plateria S.A. |

CID001585 |

| Gold |

Sichuan Tianze Precious Metals Co., Ltd. |

CID001736 |

| Gold |

Solar Applied Materials Technology Corp. |

CID001761 |

| Gold |

Sumitomo Metal Mining Co., Ltd. |

CID001798 |

| Gold |

Tanaka Kikinzoku Kogyo K.K. |

CID001875 |

| Gold |

Shandong Gold Smelting Co., Ltd. |

CID001916 |

| Gold |

Tokuriki Honten Co., Ltd. |

CID001938 |

| Gold |

Torecom |

CID001955 |

| Gold |

Umicore S.A. Business Unit Precious Metals Refining |

CID001980 |

| Gold |

United Precious Metal Refining, Inc. |

CID001993 |

| Gold |

Western Australian Mint (T/a The Perth Mint) |

CID002030 |

| Gold |

Yamakin Co., Ltd. |

CID002100 |

| Gold |

Yokohama Metal Co., Ltd. |

CID002129 |

| Gold |

Zhongyuan Gold Smelter of Zhongjin Gold Corporation |

CID002224 |

| Gold |

Gold Refinery of Zijin Mining Group Co., Ltd. |

CID002243 |

| Gold |

SAFINA A.S. |

CID002290 |

| Gold |

Umicore Precious Metals Thailand |

CID002314 |

| Gold |

MMTC-PAMP India Pvt., Ltd. |

CID002509 |

| Gold |

KGHM Polska Miedz Spolka Akcyjna |

CID002511 |

| Gold |

Singway Technology Co., Ltd. |

CID002516 |

| Gold |

Al Etihad Gold Refinery DMCC |

CID002560 |

| Gold |

Emirates Gold DMCC |

CID002561 |

| Gold |

T.C.A S.p.A |

CID002580 |

| Gold |

REMONDIS PMR B.V. |

CID002582 |

| Gold |

Korea Zinc Co., Ltd. |

CID002605 |

| Gold |

Marsam Metals |

CID002606 |

| Gold |

TOO Tau-Ken-Altyn |

CID002615 |

| Gold |

SAAMP |

CID002761 |

| Gold |

L'Orfebre S.A. |

CID002762 |

| Gold |

8853 S.p.A. |

CID002763 |

| Gold |

Italpreziosi |

CID002765 |

| Gold |

WIELAND Edelmetalle GmbH |

CID002778 |

| Gold |

Ogussa Osterreichische Gold- und Silber-Scheideanstalt GmbH |

CID002779 |

| Gold |

Bangalore Refinery |

CID002863 |

| Gold |

SungEel HiMetal Co., Ltd. |

CID002918 |

| Gold |

Planta Recuperadora de Metales SpA |

CID002919 |

| Gold |

Eco-System Recycling Co., Ltd. North Plant |

CID003424 |

| Gold |

Eco-System Recycling Co., Ltd. West Plant |

CID003425 |

| Gold |

Coimpa Industrial LTDA |

CID004010 |

| Gold |

NH Recytech Company |

CID003189 |

| Gold |

Metal Concentrators SA (Pty) Ltd. |

CID003575 |

| Tantalum |

F&X Electro-Materials Ltd. |

CID000460 |

| Tantalum |

Guangdong Rising Rare Metals-EO Materials Ltd. |

CID000291 |

| Tantalum |

XIMEI RESOURCES (GUANGDONG) LIMITED |

CID000616 |

| Tantalum |

JiuJiang JinXin Nonferrous Metals Co., Ltd. |

CID000914 |

| Tantalum |

Jiujiang Tanbre Co., Ltd. |

CID000917 |

| Tantalum |

AMG Brasil |

CID001076 |

| Tantalum |

Metallurgical Products India Pvt., Ltd. |

CID001163 |

| Tantalum |

Mineracao Taboca S.A. |

CID001175 |

| Tantalum |

Mitsui Mining and Smelting Co., Ltd. |

CID001192 |

| Tantalum |

NPM Silmet AS |

CID001200 |

| Tantalum |

Ningxia Orient Tantalum Industry Co., Ltd. |

CID001277 |

| Tantalum |

QuantumClean |

CID001508 |

| Tantalum |

Yanling Jincheng Tantalum & Niobium Co., Ltd. |

CID001522 |

| Tantalum |

Solikamsk Magnesium Works OAO |

CID001769 |

| Tantalum |

Taki Chemical Co., Ltd. |

CID001869 |

| Tantalum |

Telex Metals |

CID001891 |

| Tantalum |

Ulba Metallurgical Plant JSC |

CID001969 |

| Tantalum |

Hengyang King Xing Lifeng New Materials Co., Ltd. |

CID002492 |

| Tantalum |

D Block Metals, LLC |

CID002504 |

| Tantalum |

FIR Metals & Resource Ltd. |

CID002505 |

| Tantalum |

Jiujiang Zhongao Tantalum & Niobium Co., Ltd. |

CID002506 |

| Tantalum |

XinXing HaoRong Electronic Material Co., Ltd. |

CID002508 |

| Tantalum |

Jiangxi Dinghai Tantalum & Niobium Co., Ltd. |

CID002512 |

| Tantalum |

KEMET de Mexico |

CID002539 |

| Tantalum |

TANIOBIS Co., Ltd. |

CID002544 |

| Tantalum |

TANIOBIS GmbH |

CID002545 |

| Tantalum |

Materion Newton Inc. |

CID002548 |

| Tantalum |

TANIOBIS Japan Co., Ltd. |

CID002549 |

| Tantalum |

TANIOBIS Smelting GmbH & Co. KG |

CID002550 |

| Tantalum |

Global Advanced Metals Boyertown |

CID002557 |

| Tantalum |

Global Advanced Metals Aizu |

CID002558 |

| Tantalum |

Resind Industria e Comercio Ltda. |

CID002707 |

| Tantalum |

Jiangxi Tuohong New Raw Material |

CID002842 |

| Tantalum |

RFH Yancheng Jinye New Material Technology Co., Ltd. |

CID003583 |

| Tin |

China Tin Group Co., Ltd. |

CID001070 |

| Tin |

Tin Smelting Branch of Yunnan Tin Co., Ltd. |

CID002180 |

| Tin |

Fenix Metals |

CID000468 |

| Tin |

Mineracao Taboca S.A. |

CID001173 |

| Tin |

Minsur |

CID001182 |

| Tin |

Operaciones Metalurgicas S.A. |

CID001337 |

| Tin |

PT Timah Tbk Kundur |

CID001477 |

| Tin |

Thaisarco |

CID001898 |

| Tin |

White Solder Metalurgia e Mineracao Ltda. |

CID002036 |

| Tin |

Fabrica Auricchio Industria e Comercio Ltda. |

CID003582 |

| Tin |

Chenzhou Yunxiang Mining and Metallurgy Co., Ltd. |

CID000228 |

| Tin |

Alpha |

CID000292 |

| Tin |

Dowa |

CID000402 |

| Tin |

EM Vinto |

CID000438 |

| Tin |

Gejiu Non-Ferrous Metal Processing Co., Ltd. |

CID000538 |

| Tin |

Gejiu Zili Mining And Metallurgy Co., Ltd. |

CID000555 |

| Tin |

Gejiu Kai Meng Industry and Trade LLC |

CID000942 |

| Tin |

Malaysia Smelting Corporation (MSC) |

CID001105 |

| Tin |

Metallic Resources, Inc. |

CID001142 |

| Tin |

Mitsubishi Materials Corporation |

CID001191 |

| Tin |

Jiangxi New Nanshan Technology Ltd. |

CID001231 |

| Tin |

O.M. Manufacturing (Thailand) Co., Ltd. |

CID001314 |

| Tin |

PT Artha Cipta Langgeng |

CID001399 |

| Tin |

PT Babel Inti Perkasa |

CID001402 |

| Tin |

PT Babel Surya Alam Lestari |

CID001406 |

| Tin |

PT Bukit Timah |

CID001428 |

| Tin |

PT Mitra Stania Prima |

CID001453 |

| Tin |

PT Prima Timah Utama |

CID001458 |

| Tin |

PT Refined Bangka Tin |

CID001460 |

| Tin |

PT Sariwiguna Binasentosa |

CID001463 |

| Tin |

PT Stanindo Inti Perkasa |

CID001468 |

| Tin |

PT Timah Tbk Mentok |

CID001482 |

| Tin |

PT Timah Nusantara |

CID001486 |

| Tin |

PT Tinindo Inter Nusa |

CID001490 |

| Tin |

Rui Da Hung |

CID001539 |

| Tin |

Gejiu Yunxin Nonferrous Electrolysis Co., Ltd. |

CID001908 |

| Tin |

Yunnan Chengfeng Non-ferrous Metals Co., Ltd. |

CID002158 |

| Tin |

CV Venus Inti Perkasa |

CID002455 |

| Tin |

Magnu's Minerais Metais e Ligas Ltda. |

CID002468 |

| Tin |

Melt Metais e Ligas S.A. |

CID002500 |

| Tin |

PT ATD Makmur Mandiri Jaya |

CID002503 |

| Tin |

O.M. Manufacturing Philippines, Inc. |

CID002517 |

| Tin |

PT Cipta Persada Mulia |

CID002696 |

| Tin |

Resind Industria e Comercio Ltda. |

CID002706 |

| Tin |

Aurubis Beerse |

CID002773 |

| Tin |

Aurubis Berango |

CID002774 |

| Tin |

PT Menara Cipta Mulia |

CID002835 |

| Tin |

HuiChang Hill Tin Industry Co., Ltd. |

CID002844 |

| Tin |

Guangdong Hanhe Non-Ferrous Metal Co., Ltd. |

CID003116 |

| Tin |

Chifeng Dajingzi Tin Industry Co., Ltd. |

CID003190 |

| Tin |

PT Bangka Serumpun |

CID003205 |

| Tin |

Tin Technology & Refining |

CID003325 |

| Tin |

Ma'anshan Weitai Tin Co., Ltd. |

CID003379 |

| Tin |

PT Rajawali Rimba Perkasa |

CID003381 |

| Tin |

Luna Smelter, Ltd. |

CID003387 |

| Tin |

Yunnan Yunfan Non-ferrous Metals Co., Ltd. |

CID003397 |

| Tin |

PT Mitra Sukses Globalindo |

CID003449 |

| Tin |

PT Aries Kencana Sejahtera |

CID000309 |

| Tin |

PT Belitung Industri Sejahtera |

CID001421 |

| Tin |

PT Tommy Utama |

CID001493 |

| Tin |

PT Sukses Inti Makmur |

CID002816 |

| Tin |

CRM Synergies |

CID003524 |

| Tin |

PT Putera Sarana Shakti (PT PSS) |

CID003868 |

| Tin |

Estanho de Rondonia S.A. |

CID000448 |

| Tin |

CV Ayi Jaya |

CID002570 |

| Tin |

PT Rajehan Ariq |

CID002593 |

| Tungsten |

A.L.M.T. Corp. |

CID000004 |

| Tungsten |

Kennametal Huntsville |

CID000105 |

| Tungsten |

Guangdong Xianglu Tungsten Co., Ltd. |

CID000218 |

| Tungsten |

Chongyi Zhangyuan Tungsten Co., Ltd. |

CID000258 |

| Tungsten |

Global Tungsten & Powders LLC |

CID000568 |

| Tungsten |

Hunan Chenzhou Mining Co., Ltd. |

CID000766 |

| Tungsten |

Hunan Jintai New Material Co., Ltd. |

CID000769 |

| Tungsten |

Japan New Metals Co., Ltd. |

CID000825 |

| Tungsten |

Kennametal Fallon |

CID000966 |

| Tungsten |

Wolfram Bergbau und Hutten AG |

CID002044 |

| Tungsten |

Xiamen Tungsten Co., Ltd. |

CID002082 |

| Tungsten |

Ganzhou Jiangwu Ferrotungsten Co., Ltd. |

CID002315 |

| Tungsten |

Jiangxi Yaosheng Tungsten Co., Ltd. |

CID002316 |

| Tungsten |

Jiangxi Xinsheng Tungsten Industry Co., Ltd. |

CID002317 |

| Tungsten |

Jiangxi Tonggu Non-ferrous Metallurgical & Chemical Co., Ltd. |

CID002318 |

| Tungsten |

Malipo Haiyu Tungsten Co., Ltd. |

CID002319 |

| Tungsten |

Xiamen Tungsten (H.C.) Co., Ltd. |

CID002320 |

| Tungsten |

Jiangxi Gan Bei Tungsten Co., Ltd. |

CID002321 |

| Tungsten |

Ganzhou Seadragon W & Mo Co., Ltd. |

CID002494 |

| Tungsten |

Asia Tungsten Products Vietnam Ltd. |

CID002502 |

| Tungsten |

Hunan Shizhuyuan Nonferrous Metals Co., Ltd. Chenzhou Tungsten Products Branch |

CID002513 |

| Tungsten |

H.C. Starck Tungsten GmbH |

CID002541 |

| Tungsten |

TANIOBIS Smelting GmbH & Co. KG |

CID002542 |

| Tungsten |

Masan High-Tech Materials |

CID002543 |

| Tungsten |

Jiangwu H.C. Starck Tungsten Products Co., Ltd. |

CID002551 |

| Tungsten |

Niagara Refining LLC |

CID002589 |

| Tungsten |

China Molybdenum Tungsten Co., Ltd. |

CID002641 |

| Tungsten |

Hydrometallurg, JSC |

CID002649 |

| Tungsten |

Unecha Refractory metals plant |

CID002724 |

| Tungsten |

Philippine Chuangxin Industrial Co., Inc. |

CID002827 |

| Tungsten |

ACL Metais Eireli |

CID002833 |

| Tungsten |

Moliren Ltd. |

CID002845 |

| Tungsten |

Lianyou Metals Co., Ltd. |

CID003407 |

| Tungsten |

Hubei Green Tungsten Co., Ltd. |

CID003417 |

| Tungsten |

Cronimet Brasil Ltda |

CID003468 |

| Tungsten |

Fujian Xinlu Tungsten Co., Ltd. |

CID003609 |

Schedule B

| Albania |

Germany |

Nigeria |

| Andorra |

Ghana |

Oman |

| Angola |

Guam |

Panama |

| Argentina |

Guatemala |

Papua New Guinea |

| Armenia |

Guinea |

Peru |

| Australia |

Guyana |

Philippines |

| Austria |

Honduras |

Poland |

| Azerbaijan |

Hong Kong |

Portugal |

| Belarus |

Hungary |

Russian Federation |

| Belgium |

India |

Rwanda |

| Benin |

Indonesia |

Saudi Arabia |

| Bolivia (Plurinational State of) |

Ireland |

Senegal |

| Botswana |

Israel |

Serbia |

| Brazil |

Italy |

Sierra Leone |

| Bulgaria |

Ivory Coast |

Singapore |

| Burkina Faso |

Japan |

Slovakia |

| Burundi |

Jersey |

South Africa |

| Cambodia |

Kazakhstan |

South Sudan |

| Canada |

Kenya |

Spain |

| Central African Republic |

Korea |

Sudan |

| Chile |

Kyrgyzstan |

Suriname |

| China |

Liberia |

Sweden |

| Colombia |

Liechtenstein |

Switzerland |

| Congo |

Lithuania |

Taiwan |

| Cyprus |

Luxembourg |

Tajikistan |

| Czechia |

Madagascar |

Tanzania |

| Democratic Republic of Congo |

Malaysia |

Thailand |

| Djibouti |

Mali |

Togo |

| Dominican Republic |

Mauritania |

Turkey |

| Ecuador |

Mexico |

Uganda |

| Egypt |

Mongolia |

United Arab Emirates |

| El Salvador |

Morocco |

United Kingdom |

| Eritrea |

Mozambique |

United States |

| Estonia |

Myanmar |

Urugay |

| Ethiopia |

Namibia |

Uzbekistan |

| Fiji |

Netherlands |

Viet Nam |

| Finland |

New Zealand |

Zambia |

| France |

Nicaragua |

|

| Georgia |

Niger |

|

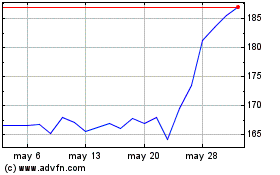

Ralph Lauren (NYSE:RL)

Gráfica de Acción Histórica

De Dic 2024 a Ene 2025

Ralph Lauren (NYSE:RL)

Gráfica de Acción Histórica

De Ene 2024 a Ene 2025