NOT FOR DISTRIBUTION TO UNITED STATES NEWSWIRE SERVICES OR FOR DISSEMINATION IN

THE UNITED STATES

Perseus Mining Limited ("Perseus" or the "Company") (TSX:PRU)(ASX:PRU) is

pleased to provide details of further high grade gold intercepts recorded during

recent drilling on the Bokitsi South Deposit at its Edikan Gold Mine (EGM) in

Ghana, West Africa. (Refer to Figure 1 - Location Map). Bokitsi South is the

first of a number of targets to be drill tested with the aim of identifying high

grade mineralisation that can be included in mill feed for the EGM processing

plant.

The drill results which are in addition to the positive drill results described

in our News Release dated 19 June 2014, include the following highlights:

BKRC083 - 16m at 6.4g/t Au from 43m including 3m at 26.7g/t Au from 44m

BKRC084 - 24m at 4.6g/t Au from 60m including 2m at 18.9g/t Au from 68m

BKRC086 - 3m at 5.6g/t Au from 27m (drill hole ended in mineralisation)

BKRC093 - 6m at 8.7g/t Au from 9m including 3m at 16.1g/t Au from 10m

BKRC099 - 4m at 10.8g/t Au from 72m including 1m at 36.0g/t Au from 73m

BKDD048 - 8.7m at 8.7g/t Au from 67.5m including 2.4m at 18.6g/t Au from

72.6m

The Bokitsi drill programme included 37 RC drill holes totalling 2,973 metres.

The drill intercepts summarised above are from the final 22 drill holes of the

programme and are in addition to results from the first 15 drill holes announced

previously. Significant intercepts from all holes in the drill programme are

listed in Table 1 of Attachment 1. Apart from the three holes that were diamond

core tailed due to the presence of water, the predominantly RC drilling program

was conducted with dry samples. (Refer to Figure 2 for a plan of the Bokitsi

South deposit and to Figure 3 for a vertical longitudinal section.)

This drilling programme targeted areas containing Inferred Mineral Resources at

Bokitsi South, as well as testing the southern extent of the lode. The drill

results from the programme will now be incorporated into a revised estimation of

the Mineral Resources at Bokitsi South which will be published early in the

September 2014 Quarter. A maiden Mineral Reserve estimate for the Bokitsi South

deposit based on the updated Mineral Resource data is expected to be released

late in the September 2014 Quarter.

----------------------------------------------------------------------------

Perseus Managing Director, Jeff Quartermaine's Comments:

"We continue to be very encouraged by the results from the Bokitsi South

drill programme. A Mineral Resource upgrade and maiden Mineral Reserve

estimate will now be prepared for the deposit and studies to assess the

feasibility of bringing forward the development of the Bokitsi pit will

commence.

Bokitsi South is one of several deposits and prospects on our Edikan

tenements, including Chirawewa, Mampong and Pokukrom, where our exploration

programmes are targeting high grade mineralisation to enhance the grade of

mill feed at our Edikan Gold Mine.

We consider that organic growth is the most cost efficient method of growth

for mining companies and the recent results from the Bokitsi South drilling

programme indicate that our corporate strategy of pursuing growth through

the drill bit is delivering positive results as planned."

----------------------------------------------------------------------------

The Bokitsi sediment shear hosted mineralized zone extends along the western

flank of the Fetish deposit to 1.5 kilometres to the south. Mineralisation is

contained in a 5 to 25 metre wide shear zone in volcaniclastic sediments with

silica-sericite alteration, quartz veining and 1 to 3% pyrite plus arsenopyrite.

While the granite hosted deposits at Edikan tend to be wide and low grade, the

sediment shear hosted deposits are narrower with significantly higher grade.

Two discrete deposits have been delineated on the trend, including Bokitsi North

which is located immediately west of the Fetish deposit and Bokitsi South. Oxide

ore was mined from both deposits in the 1990s, with the Bokitsi South lode

exploited by Ashanti Goldfields.

Metallurgical test work conducted on the Bokitsi South gold mineralised material

indicates that it is amenable to processing through the EGM circuit at

marginally lower recoveries than the Edikan granite orebodies.

The drilling program on Bokitsi South has infill-drilled the principal sulphide

lode below the old oxide pit to a nominal 20m by 20m drill spacing and extended

the drill testing to the south in order to expand and upgrade the Mineral

Resource.

Competent Person Statement:

The information in this report and attachments 1 and 2 that relates to

exploration results is based on, and fairly represents, information and

supporting documentation prepared by Mr Kevin Thomson, a Competent Person who is

a Professional Geoscientist with the Association of Professional Geoscientists

of Ontario. Mr Thomson is an employee of a subsidiary of the Company. Mr Thomson

has sufficient experience, which is relevant to the style of mineralisation and

type of deposit under consideration and to the activity being undertaken, to

qualify as a Competent Person as defined in the 2012 Edition of the

'Australasian Code for Reporting of Exploration Results, Mineral Resources and

Ore Reserves'") and to qualify as a "Qualified Person" under National Instrument

43-101 - Standards of Disclosure for Mineral Projects ("NI 43-101"). Mr Thomson

consents to the inclusion in this report of the matters based on his information

in the form and context in which it appears. For a description of Perseus' data

verification process, quality assurance and quality control measures, the

effective date of the mineral resource and mineral reserve estimates contained

herein, details of the key assumptions, parameters and methods used to estimate

the mineral resources and reserves set out in this report and the extent to

which the estimate of mineral resources or mineral reserves set out herein may

be materially affected by any known environmental, permitting, legal, title,

taxation, socio-political, marketing or other relevant issues, readers are

directed to the technical report entitled "Technical Report - Central Ashanti

Gold Project, Ghana" dated May 30, 2011 and the technical report entitled

"Technical Report - Tengrela Gold Project, Cote d'Ivoire" dated December 22,

2010 in relation to the Edikan Gold Mine (formerly the Central Ashanti Gold

Project) and the Tengrela Gold Project respectively.

Caution Regarding Forward-Looking Information: This report contains

forward-looking information which is based on the assumptions, estimates,

analysis and opinions of management made in light of its experience and its

perception of trends, current conditions and expected developments, as well as

other factors that management of the Company believes to be relevant and

reasonable in the circumstances at the date that such statements are made, but

which may prove to be incorrect. Assumptions have been made by the Company

regarding, among other things: the price of gold, continuing commercial

production at the Edikan Gold Mine without any major disruption, development of

a mine at Tengrela, the receipt of required governmental approvals, the accuracy

of capital and operating cost estimates, the ability of the Company to operate

in a safe, efficient and effective manner and the ability of the Company to

obtain financing as and when required and on reasonable terms. Readers are

cautioned that the foregoing list is not exhaustive of all factors and

assumptions which may have been used by the Company. Although management

believes that the assumptions made by the Company and the expectations

represented by such information are reasonable, there can be no assurance that

the forward-looking information will prove to be accurate. Forward-looking

information involves known and unknown risks, uncertainties, and other factors

which may cause the actual results, performance or achievements of the Company

to be materially different from any anticipated future results, performance or

achievements expressed or implied by such forward-looking information. Such

factors include, among others, the actual market price of gold, the actual

results of current exploration, the actual results of future exploration,

changes in project parameters as plans continue to be evaluated, as well as

those factors disclosed in the Company's publicly filed documents. The Company

believes that the assumptions and expectations reflected in the forward-looking

information are reasonable. Assumptions have been made regarding, among other

things, the Company's ability to carry on its exploration and development

activities, the timely receipt of required approvals, the price of gold, the

ability of the Company to operate in a safe, efficient and effective manner and

the ability of the Company to obtain financing as and when required and on

reasonable terms. Readers should not place undue reliance on forward-looking

information. Perseus does not undertake to update any forward-looking

information, except in accordance with applicable securities laws.

Figure 1. Location of the Bokitsi South Deposit, Figure 2. Plan Map of the

Bokitsi South Resource Infill Drilling, and Figure 3. Vertical Longitudinal

Section of the Bokitsi South Deposit with Recent Infill Drilling Highlighted are

available at the following address:

http://media3.marketwire.com/docs/140701_PerseusMiningLimited_Figure1-2-3.pdf

ATTACHMENT 1 - EDIKAN DRILLING RESULTS

Table 1: Bokitsi South Resource Infill Drilling Results

----------------------------------------------------------------------------

----------------------------------------------------------------------------

Hole East North RL Depth Azm. Incl. From To Width Au

(m) (m)(m ASL) (m) (degrees) (degrees) (m) (m) (m) g/t

----------------------------------------------------------------------------

----------------------------------------------------------------------------

BKRC068 2,807 4,400 157 115 307 -50 97 104 7 3.6

----------------------------------------------------------------------------

BKRC069 2,800 4,380 155 105 307 -55 92 96 4 9.2

incl. 92 94 2 17.7

----------------------------------------------------------------------------

BKRC070 2,786 4,340 156 95 307 -45 75 88 13 5.7

incl. 77 82 5 12.6

----------------------------------------------------------------------------

BKRC071 2,803 4,300 159 110 307 -55 91 100 9 2.1

----------------------------------------------------------------------------

BKRC072 2,808 4,260 157 110 307 -55 83 94 11 4.4

incl. 83 85 2 9.1

----------------------------------------------------------------------------

BKRC073 2,793 4,240 151 120 307 -50 56 82 26 1.6

92 94 2 2.9

----------------------------------------------------------------------------

BKRC074 2,770 4,220 149 72 307 -45 44 59 15 4.2

incl. 47 50 3 7.4

and 56 58 2 11.6

----------------------------------------------------------------------------

BKRC075 2,781 4,220 149 84 307 -55 32 33 1 9.5

53 60 7 5.4

incl. 54 56 2 12.4

63 66 3 8.6

incl. 64 65 1 17.6

----------------------------------------------------------------------------

BKRC076 2,819 4,220 153 100 307 -55 90 97 7 6.4

incl. 91 94 3 12.8

----------------------------------------------------------------------------

BKRC077 2,769 4,380 154 65 307 -45 53 62 9 6.8

incl. 55 57 2 12.1

----------------------------------------------------------------------------

BKRC078 2,759 4,400 155 60 307 -45 40 51 11 7.4

incl. 40 44 4 14.3

----------------------------------------------------------------------------

BKRC079 2,775 4,320 157 90 307 -45 66 76 10 6.7

incl. 71 74 3 12.3

----------------------------------------------------------------------------

BKRC080 2,774 4,280 154 120 307 -45 66 68 2 2.6

71 72 1 24.8

111 118 7 1.0

----------------------------------------------------------------------------

BKRC081 2,783 4,260 153 110 307 -45 45 47 2 1.5

67 87 20 8.6

incl. 67 70 3 30.5

and 79 83 4 11.4

----------------------------------------------------------------------------

BKRC082 2,774 4,240 150 112 307 -45 55 56 1 6.9

59 66 7 5.8

incl. 63 65 2 10.0

80 84 4 1.0

----------------------------------------------------------------------------

BKRC083 2760.1 4199.9 148.3 96 270 -50 14 18 4 1.3

43 59 16 6.4

incl. 44 47 3 26.7

----------------------------------------------------------------------------

BKRC084 2800.0 4199.8 149.5 100 270 -50 60 84 24 4.6

incl. 68 70 2 18.9

77 80 3 13

----------------------------------------------------------------------------

BKRC085 2720.4 4159.9 150.7 36 270 -55 5 9 4 1.2

----------------------------------------------------------------------------

BKRC086 2740.4 4140.0 151.5 30 270 -55 27 30 3(i) 5.6

----------------------------------------------------------------------------

BKRC087 2740.6 4120.0 153.3 30 270 -55 NSI

----------------------------------------------------------------------------

BKRC088 2730.6 4080.0 166.6 36 270 -55 NSI

----------------------------------------------------------------------------

BKRC089 2735.0 4159.9 149.1 45 270 -50 NSI

----------------------------------------------------------------------------

BKRC090 2738.9 4039.9 168.1 36 270 -55 3 8 5 1.2

32 35 3 6.1

----------------------------------------------------------------------------

----------------------------------------------------------------------------

----------------------------------------------------------------------------

----------------------------------------------------------------------------

Hole East North RL Depth Azm. Incl. From To Width Au

(m) (m)(m ASL) (m)(degrees)(degrees) (m) (m) (m) g/t

----------------------------------------------------------------------------

----------------------------------------------------------------------------

BKRC091 2740.2 4060.0 167.1 36 270 -55 29 36 7(i) 2.8

----------------------------------------------------------------------------

BKRC092 2740.5 4099.9 161.7 36 270 -55 35 36 1(i) 1.9

----------------------------------------------------------------------------

BKRC093 2740.4 4020.0 166.1 36 270 -55 9 15 6 8.7

incl. 10 13 3 16.1

----------------------------------------------------------------------------

BKRC094 2720.1 3999.9 165.2 24 270 -55 14 15 1 5.7

----------------------------------------------------------------------------

BKRC095 2740.2 3979.9 157.9 30 270 -55 NSI

----------------------------------------------------------------------------

BKRC096 2810.0 4180.5 150.0 114 270 -55 75 86 11 1.9

----------------------------------------------------------------------------

BKRC097 2790.1 4179.9 149.6 95 270 -50 30 46 16 3.3

56 58 2 48.2

58 59 1 3.2

64 68 4 2

----------------------------------------------------------------------------

BKRC098 2769.7 4179.9 149.9 90 270 -45 40 42 2 1.7

58 60 2 2.1

----------------------------------------------------------------------------

BKRC099 2801.7 4160.0 149.4 102 270 -50 72 76 4 10.8

incl. 73 74 1 36

92 96 4 2

----------------------------------------------------------------------------

BKRC100 2788.7 4140.0 149.7 96 270 -50 54 67 13 1

80 88 8 2.6

----------------------------------------------------------------------------

BKRC101 2769.3 4140.2 149.7 90 270 -45 NSI

----------------------------------------------------------------------------

BKRDD047 2832.3 4320.0 162.7 136 270 -55 114 124 10 1.4

----------------------------------------------------------------------------

BKRDD048 2776.7 4299.8 155.3 130 270 -45 67.5 76.2 8.7 8.7

incl. 72.6 75 2.4 18.6

----------------------------------------------------------------------------

BKRDD049 2768.0 4160.0 150.0 81 270 -50 NSI

----------------------------------------------------------------------------

Note:

1. NSI means "No significant intercept"

2. "(i)\" denotes drill hole ends in mineralisation

ATTACHMENT 2 - JORC CODE, 2012 Edition - Table 1

Section 1 Sampling Techniques and Data

----------------------------------------------------------------------------

Criteria JORC Code Explanation Commentary

----------------------------------------------------------------------------

Sampling techniques

Nature and quality of Reverse Circulation (RC)

sampling (eg cut channels,drill holes (BKRC holes)

random chips, or specific were routinely sampled at

specialised industry 1m intervals down the

standard measurement toolshole. RC samples were

appropriate to the collected at the drill rig

minerals under by riffle splitting drill

investigation, such as spoils to collect a

down hole gamma sondes, ornominal 1-2 kg sub sample

handheld XRF instruments, and composited into 2m

etc). These examples samples for assay of

should not be taken as unmineralised hanging-wall

limiting the broad meaningmaterial, and 1m samples

of sampling. were submitted for assay

Include reference to of the mineralised zones.

measures taken to ensure Diamond drill (DD) core in

sample representivity and BKRD holes was sampled at

the appropriate 1m intervals by sawing in

calibration of any half the drill core and

measurement tools or submitting half for assay.

systems used. Routine standard reference

Aspects of the material, sample blanks,

determination of and sample field

mineralisation that are duplicates were

Material to the Public inserted/collected at

Report. every 12th sample in the

In cases where 'industry sample sequence on average

standard' work has been in order to gauge and

done this would be ensure sample

relatively simple (eg representivity and quality

'reverse circulation of results from the

drilling was used to laboratory.

obtain 1 m samples from All samples were submitted

which 3 kg was pulverised to Intertek Minerals Ghana

to produce a 30 g charge in Tarkwa for preparation

for fire assay'). In otherand analysis for Gold by

cases more explanation may50g Fire Assay with AAS

be required, such as wherefinish.

there is coarse gold that

has inherent sampling

problems. Unusual

commodities or

mineralisation types (eg

submarine nodules) may

warrant disclosure of

detailed information.

----------------------------------------------------------------------------

Drilling techniques

Drill type (eg core, All RC holes were

reverse circulation, open-completed by reverse

hole hammer, rotary air circulation (RC) drilling

blast, auger, Bangka, techniques with a hole

sonic, etc) and details diameter of 5.5 inch and a

(eg core diameter, triple face sampling down hole

or standard tube, depth ofhammer.

diamond tails, face- Three diamond core tails

sampling bit or other were drilled with an NQ

type, whether core is diameter coring bit.

oriented and if so, by

what method, etc).

----------------------------------------------------------------------------

Drill sample recovery

Method of recording and A qualitative estimate of

assessing core and chip sample recovery was done

sample recoveries and for each sample metre

results assessed. collected from the drill

Measures taken to maximiserig.

sample recovery and ensureRiffle split samples were

representative nature of weighed to ensure

the samples. consistency of sample size

Whether a relationship and monitor sample

exists between sample recoveries.

recovery and grade and Drill sample recovery and

whether sample bias may quality is considered to

have occurred due to be adequate for the

preferential loss/gain of drilling technique

fine/coarse material. employed. Wet RC samples

were not an issue as the

RC drill rig had

sufficient air pressure to

ensure dry samples.

----------------------------------------------------------------------------

Logging

Whether core and chip All drill samples were

samples have been geologically logged by

geologically and Company Geologists.

geotechnically logged to aGeological logging

level of detail to supportrecorded rock types,

appropriate Mineral visual estimates of the

Resource estimation, abundance of quartz

mining studies and fragments and sulphides

metallurgical studies. plus the degree of

Whether logging is weathering using a

qualitative or standardized logging

quantitative in nature. system.

Core (or costean, channel,All (100%) of material

etc) photography. drilled via RC and DD

The total length and drilling methods was

percentage of the relevantlogged in detail by

intersections logged. Company geologists.

Small samples of RC drill

material were retained in

chip trays and DD core

stored in core trays for

future reference and

validation of geological

logging.

----------------------------------------------------------------------------

Sub-sampling techniques

and sample preparation If core, whether cut or All dry samples were

sawn and whether quarter, riffle split at the drill

half or all core taken. rig. Wet RC samples were

If non-core, whether not encountered in this

riffled, tube sampled, program. When chips were

rotary split, etc and showing signs of moisture,

whether sampled wet or the drilling switched to

dry. diamond core to avoid wet

For all sample types, the chips in several holes.

nature, quality and Routine field sample

appropriateness of the duplicates of RC samples

sample preparation were taken to evaluate

technique. representivity of samples

Quality control procedureswith the results stored in

adopted for all sub- the master drill database

sampling stages to for reference.

maximise representivity ofAt the Intertek Minerals

samples. Ghana laboratory, samples

Measures taken to ensure were weighed, dried and

that the sampling is crushed to -2mm in a jaw

representative of the in crusher. A 1.5kg split of

situ material collected, the crushed sample was

including for instance subsequently pulverised in

results for field a ring mill to achieve a

duplicate/second-half nominal particle size of

sampling. 85% passing 75um.

Whether sample sizes are Sample sizes and

appropriate to the grain laboratory preparation

size of the material beingtechniques are considered

sampled. to be appropriate for this

stage of gold exploration.

----------------------------------------------------------------------------

Quality of assay data

and laboratory tests The nature, quality and For all drill samples,

appropriateness of the analysis for Gold was

assaying and laboratory undertaken at the Intertek

procedures used and Minerals Ghana laboratory

whether the technique is by 50g Fire Assay with AAS

considered partial or finish to a lower

total. detection limit of

For geophysical tools, 0.01ppm. Fire assay is

spectrometers, handheld considered a total assay

XRF instruments, etc, the technique.

parameters used in No geophysical tools or

determining the analysis other non-assay

including instrument make instruments were used in

and model, reading times, the analyses reported.

calibrations factors Review of standard

applied and their reference material, sample

derivation, etc. blanks and duplicates

Nature of quality control suggest there are no

procedures adopted (eg significant analytical

standards, blanks, bias or preparation errors

duplicates, external in the reported analyses.

laboratory checks) and Internal laboratory QAQC

whether acceptable levels checks are reported by the

of accuracy (ie lack of laboratory and routine

bias) and precision have review of the laboratory

been established. QAQC suggests the

laboratory is performing

within acceptable limits.

----------------------------------------------------------------------------

Verification of sampling

and assaying The verification of Drill hole data is

significant intersections captured by Company

by either independent or geologists at the drill

alternative company rig and manually entered

personnel. into a digital database.

The use of twinned holes. The digital data is

Documentation of primary verified and validated by

data, data entry the Company's database

procedures, data Manager before loading

verification, data storageinto a master drill hole

(physical and electronic) database on a regularly

protocols. backed-up server.

Discuss any adjustment to Reported drill hole

assay data. intercepts are compiled by

the Company's Group

Exploration Manager.

Twin holes were not

drilled to verify results

as it is considered

unnecessary at this stage

of drilling.

There were no adjustments

to assay data.

----------------------------------------------------------------------------

Location of data points

Accuracy and quality of Drill hole collars were

surveys used to locate set out in a local grid

drill holes (collar and datum using a Total

down-hole surveys), Station, with a number of

trenches, mine workings well-established survey

and other locations used bench marks for control.

in Mineral Resource Drill hole collars were

estimation. picked up after drilling

Specification of the grid with a Total Station and

system used. cross-checked with a DGPS

Quality and adequacy of in UTM WGS84 Zone 30N. The

topographic control. accuracy in lateral and

vertical directions is

considered to be within

millimetres.

Drill holes were surveyed

for down hole deviation

using a Reflex EZ-Shot

tool, at 12m and 30m

depth, and every 30m depth

thereafter, plus at the

end-of-hole.

Locational accuracy at

collar and down the drill

hole is considered

appropriate for this stage

of drilling.

----------------------------------------------------------------------------

Data spacing and

distribution Data spacing for reportingThe drilling program was

of Exploration Results. one of infill drilling for

Whether the data spacing an eventual resource

and distribution is update. Previous drilling

sufficient to establish was in-filled to a nominal

the degree of geological spacing of 20 meters X 20

and grade continuity meters in this program.

appropriate for the The reported drilling is

Mineral Resource and Ore sufficient to establish

Reserve estimation geological and grade

procedure(s) and continuity and will be

classifications applied. used for a future resource

Whether sample compositingupdate of the deposit.

has been applied. Sample compositing was

performed only in the

sampled hang-wall waste

material with 2 X 1m

sample composites, however

sample compositing was not

performed in the

mineralised zones and the

original 1 metre samples

were submitted for assay.

----------------------------------------------------------------------------

Orientation of data in

relation to geological Whether the orientation ofIn plan, drilling has been

structure sampling achieves unbiasedperformed approximately

sampling of possible perpendicular to the

structures and the extent strike of controlling

to which this is known, structures and the

considering the deposit mineralisation. In cross-

type. section, drill holes were

If the relationship drilled at high angles to

between the drilling the dip of structures and

orientation and the mineralisation.

orientation of key The drilling has largely

mineralised structures is been drilled at high angle

considered to have to the mineralisation and

introduced a sampling a sampling bias is not

bias, this should be expected to have been

assessed and reported if introduced.

material.

----------------------------------------------------------------------------

Sample security

The measures taken to Samples were stored in a

ensure sample security. fenced compound within the

Company's Edikan Mine Site

until being collected at

site by Intertek Minerals

Ghana vehicles and

transported to their

laboratory in Tarkwa.

----------------------------------------------------------------------------

Audits or reviews

The Company's sampling

techniques employed in

The results of any audits Ghana were last reviewed

or reviews of sampling in a site visit to the

techniques and data. Edikan Gold Mine by

consultants Runge Limited

(now RungePincockMinarco

Limited) in October of

2010 and are deemed to be

of industry standard and

satisfactory.

----------------------------------------------------------------------------

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section.)

----------------------------------------------------------------------------

Criteria JORC Code Explanation Commentary

----------------------------------------------------------------------------

Mineral tenement and

land tenure status Type, reference The reported results are

name/number, location and from the Ayanfuri Mining

ownership including Lease, permit ML1110/1994.

agreements or material The Ayanfuri Mining Lease

issues with third parties is located in the Central

such as joint ventures, Region of Ghana and is

partnerships, overriding owned by Perseus Mining

royalties, native title (Ghana) Limited, a 90%

interests, historical owned subsidiary of

sites, wilderness or Perseus Mining Limited,

national park and with the remaining 10%

environmental settings. owned by the Government of

The security of the tenureGhana. A production

held at the time of royalty of 5% is due to

reporting along with any the government of Ghana

known impediments to and royalties totalling

obtaining a licence to 1.75% are due to other

operate in the area. parties.

The Ayanfuri Mining Lease

is in good standing, valid

through to 30 December

2024.

----------------------------------------------------------------------------

Exploration done by

other parties Acknowledgment and Historical exploration and

appraisal of exploration mining was conducted on

by other parties. the property from the

early 1990s up to 2001 by

Cluff Mining (Ghana) Ltd

and Ashanti Goldfields

Corp.

The past exploration was

successful and resulted in

multiple discoveries

leading to mining.

----------------------------------------------------------------------------

Geology

Deposit type, geological The Ayanfuri Mining Lease

setting and style of is situated within the

mineralisation. Paleo-Proterozoic Birimian

of Southern Ghana, being

located in the Kumasi

Basin sedimentary group

approximately 5 to 8

kilometres west of the

Ashanti Greenstone Belt.

The subject of this

drilling program was the

Bokitsi South deposit,

which is a sedimentary

shear-hosted Orogenic gold

deposit. Host rocks

consist of mainly

volcaniclastic and

epiclastic meta-sediments

and gold mineralisation is

situated in a silica-

sericite altered shear

zone with quartz veining

plus up to 3% disseminated

pyrite and arsenopyrite.

----------------------------------------------------------------------------

Drill hole Information

A summary of all Reported results are

information material to summarised in Table 1

the understanding of the within the attached

exploration results announcement.

including a tabulation of The drill holes reported

the following information in this announcement have

for all Material drill the following parameters:

holes:

All drill holes have been

easting and northing of reported for which results

the drill hole collar have been received.

elevation or RL (Reduced Grid co-ordinates are a

Level - elevation above local mine grid with the

sea level in metres) of baseline oriented at 38

the drill hole collar deg. east of true north.

dip and azimuth of the Collar elevation is

hole defined as height above

down hole length and sea level in metres (RL)

interception depth and has been determined

hole length with a DGPS.

Dip is the inclination of

If the exclusion of this the hole from the

information is justified horizontal. Azimuth is

on the basis that the reported relative to the

information is not local grid as the

Material and this direction toward which the

exclusion does not detracthole is drilled.

from the understanding of Down hole length of the

the report, the Competent hole is the distance from

Person should clearly the surface to the end of

explain why this is the the hole, as measured

case. along the drill trace

Intersection depth is the

distance down the hole as

measured along the drill

trace.

Intersection width is the

down hole distance of an

intersection as measured

along the drill trace

Hole length is the

distance from the surface

to the end of the hole, as

measured along the drill

trace.

Table 1 reports all of the

drilling results from this

program and repeats

initial results first

reported on June 19, 2014.

----------------------------------------------------------------------------

Data aggregation methods

In reporting Exploration Drill hole intercepts are

Results, weighting reported from 1m metre

averaging techniques, down hole samples.

maximum and/or minimum A minimum cut-off grade of

grade truncations (eg 0.5 g/t Au is applied to

cutting of high grades) the reported intervals.

and cut-off grades are Maximum internal dilution

usually Material and is 2m within a reported

should be stated. interval.

Where aggregate interceptsNo grade top cut-off has

incorporate short lengths been applied.

of high grade results and No metal equivalent

longer lengths of low reporting is used or

grade results, the applied.

procedure used for such

aggregation should be

stated and some typical

examples of such

aggregations should be

shown in detail.

The assumptions used for

any reporting of metal

equivalent values should

be clearly stated.

----------------------------------------------------------------------------

Relationship between

mineralisation widths These relationships are Previous drilling has well

and intercept lengths particularly important in established the geometry

the reporting of and orientation of the

Exploration Results. mineralisation being

If the geometry of the drilled in this program,

mineralisation with and drilling has been

respect to the drill hole planned to be nearly

angle is known, its natureperpendicular to the

should be reported. strike and dip of the

If it is not known and mineralisation.

only the down hole lengthsThe mineralised zone dips

are reported, there shouldon average 50 deg to the

be a clear statement to southeast, and drilling

this effect (eg 'down holewas inclined at -50 to -45

length, true width not to the northwest. True

known'). thicknesses of drill

intercepts ranges between

approximately 85% and 100%

of the down-hole length.

Results are reported as

down hole length.

----------------------------------------------------------------------------

Diagrams

Appropriate maps and Figure 1 is a general

sections (with scales) andlocation map of the

tabulations of intercepts Bokitsi South deposit,

should be included for anyrelative to other deposits

significant discovery at the Edikan Gold Mine.

being reported These Figure 2 is a plan map of

should include, but not beprevious and recent drill

limited to a plan view of hole collars at Bokitsi

drill hole collar South.

locations and appropriate Figure 3 is a vertical

sectional views. Longitudinal Section of

the Bokitsi South deposit

highlighting recent infill

drilling with intercepts

greater than 50

gramsXmeters annotated.

----------------------------------------------------------------------------

Balanced reporting

Where comprehensive All drill holes drilled in

reporting of all this program are shown in

Exploration Results is notFigure 2 (Drill Plan).

practicable,

representative reporting

of both low and high

grades and/or widths

should be practiced to

avoid misleading reporting

of Exploration Results.

----------------------------------------------------------------------------

Other substantive

exploration data Other exploration data, ifThere is no other

meaningful and material, exploration data which is

should be reported considered material to the

including (but not limitedresults reported in this

to): geological announcement.

observations; geophysical

survey results;

geochemical survey

results; bulk samples -

size and method of

treatment; metallurgical

test results; bulk

density, groundwater,

geotechnical and rock

characteristics; potential

deleterious or

contaminating substances.

----------------------------------------------------------------------------

Further work

The nature and scale of Limited infill drilling

planned further work (eg may be planned to test in

tests for lateral further detail the

extensions or depth northern and southern

extensions or large-scale extensions of the Bokitsi

step-out drilling). South deposit at shallow

Diagrams clearly levels.

highlighting the areas of An update to the Bokitsi

possible extensions, South deposit resource is

including the main planned for the September

geological interpretations2014 Quarter.

and future drilling areas,

provided this information

is not commercially

sensitive.

----------------------------------------------------------------------------

FOR FURTHER INFORMATION PLEASE CONTACT:

To discuss any aspect of this announcement, please contact:

Perseus Mining Limited

Managing Director:

Jeff Quartermaine

+61 8 6144 1700

jeff.quartermaine@perseusmining.com (Perth)

Perseus Mining Limited

Investor Relations:

Nathan Ryan

+61 4 20 582 887

nathan.ryan@nwrcommunications.com.au (Melbourne)

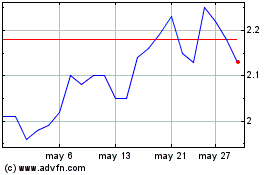

Perseus Mining (TSX:PRU)

Gráfica de Acción Histórica

De May 2024 a Jun 2024

Perseus Mining (TSX:PRU)

Gráfica de Acción Histórica

De Jun 2023 a Jun 2024