Orezone Gold Corporation (TSX:ORE) is pleased to provide an update

on a recently completed metallurgical study and the latest drill

results for its wholly owned Bondi Gold Project in Burkina Faso,

West Africa. Bondi is the Company's second tier project with an NI

43-101 qualified resource of 282,000 oz of Measured and Indicated

resources (4.2 Mt @ 2.1 g/t) and 149,700 oz of Inferred resources

(2.5 Mt @ 1.8 g/t).

Metallurgical Highlights

-- Direct agitated cyanidation recoveries averaged 94% for oxide, 93% for

semi-oxidized and 91% for sulphide material.

-- Recoveries were greater than or equal to 90% for all of the composite

samples at all grind sizes between 75 micrometre to 106 micrometre,

irrespective of the cyanide concentration used (0.5 to 2.0 gNaCN/L).

-- Rapid gold recovery at all feed sizes; 6 to 12 hours for oxide and

within 12 hours for sulphide.

-- Sulphide samples responded well to the scoping flotation testing at a

grind size of 75 um with 88.3% of the gold recovered in 4.3% of the feed

weight for a composite sample with a grade of 2.2 g/t, and 91.6% of the

gold recovered in 6.8% of the feed weight for a composite sample with a

grade of 6.9 g/t.

Drilling Highlights

-- New infill core holes within the inferred resources were broadly in line

with the resource model and will assist to upgrade those resources to

the indicated category.

-- New RC holes tested auger drill anomalies generated in 2012, extending

zone 372 by about 275 m to the SE, and intersected gold mineralization

about 1,500 m to the south of zone 2S, in the same host rock (porphyry).

Many of the better auger anomalies remain untested.

-- A Mobile Metal Ions (MMI(TM)) geochemical survey test was completed over

a 400 m section where two blind deposits are present (Zone 2NW and 2NE):

the test was conclusive, with a strong gold anomaly over the blind

deposits where conventional soil chemistry did not work. This will be

useful for future target generation and prioritization where the

geophysics indicates strong structures and the conventional soil

geochemistry has been weak.

Metallurgical Study

A suite of thirty-six samples representative of Bondi oxide,

sulphide and mixed gold-bearing material were submitted to

McClelland Laboratories in Sparks, Nevada last year for detailed

head analysis to characterize the samples by grade, cyanide

solubility, elemental make-up and carbon and sulphide content.

Direct agitated cyanidation tests were performed on all samples at

a feed size of 80% passing 75 micrometre and a cyanide

concentration of 1.0 g NaCN/L for a standard leach time of 72

hours. The majority of the samples were then combined into four

different composites that represented medium grade oxide (MGO),

high grade oxide (HGO), medium grade sulphide (MGS) and high grade

sulphide (HGS) material. Metallurgical testing of the four

composite samples included:

-- direct agitated cyanidation at various feed sizes to determine gold and

silver recoveries, recovery rate, reagent consumption and feed size

sensitivity;

-- direct agitation at various cyanide concentrations to determine optimum

cyanide dosing;

-- mechanically agitated cyanidation to evaluate the benefits of sparging

and the addition of lead nitrate; and

-- Carbon-in-leach (CIL) mechanically agitated cyanidation to determine the

effects of adding activated carbon during leaching.

In addition, metallurgical testing of the two sulphide composite

samples included scoping level bulk sulphide flotation at a feed

size of 80% passing 75 micrometre, followed by further testing at

other feed sizes between 80% passing 106 micrometre and 80% passing

53 micrometre.

Two master composite samples were prepared for gravity testing,

combining the MGO and HGO variability samples into an Oxide Master

Composite (Oxide MC) and the MGS and HGS variability samples into a

Sulphide Master Composite (Sulphide MC), which were both subjected

to:

-- scoping level gravity concentration to evaluate recovery using a Knelson

concentrator;

-- extended gravity recoverable gold (E-GRG) to determine the GRG content

of the composite and the distribution of the GRG by particle size; and

-- agitated cyanidation on gravity concentration products to determine

response to cyanidation and optimum leaching conditions for both gravity

concentrate and gravity tails;

A petrographic study of the four composite samples was completed

by Economic Geology Consultants from Reno, NV, USA.

Orezone submitted a suite of nineteen whole PQ core samples

representative of Bondi oxide, sulphide and mixed gold-bearing

material to McClelland Laboratories in June 2012. McClelland

submitted in July 2012 four composite whole PQ core samples of

oxide (2) and sulphide (2) gold-bearing material to Hazen Research

Inc. from Golden, CO, USA, for comminution test work that yielded

the following results:

----------------------------------------------------------------------------

Comminution Test Oxide Oxide Fresh Fresh

(I1) (S3) (I1) (S3)

----------------------------------------------------------------------------

Bond ball mill work index kWh/t 5.9 4.0 21.0 18.1

----------------------------------------------------------------------------

Bond crusher work index kWh/t 1.8 1.9 14.3 8.7

----------------------------------------------------------------------------

Bond abrasion index Gram 0.001 0.009 0.145 0.053

----------------------------------------------------------------------------

Unconfined Compressive Strength Psi

(UCS) 15,960 11,530

----------------------------------------------------------------------------

Overall AG-SAG hardness (A x b) 473 584 36 68

----------------------------------------------------------------------------

Drop Weight Index kWh/m3 0.6 0.5 8.1 4.1

----------------------------------------------------------------------------

Conclusions of the McClelland Laboratories Metallurgical report

were:

-- Overall metallurgical performance of the oxide and sulphide gold-bearing

materials was very similar;

-- All variability samples were amenable to whole ore milling cyanidation

treatment at a feed size of 80% passing 75 micrometre and a cyanide

concentration of 1.0 g NaCN/L;

-- Maximum or near maximum gold recoveries for the oxide composites were

obtained at a feed size of 80% passing 75 micrometre;

-- Maximum or near maximum gold recoveries for the sulphide composites were

obtained at a feed size of 80% passing 53 micrometre;

-- Maximum or near maximum gold recoveries for the oxide composites were

obtained at a cyanide concentration of 0.5 gNaCN/L (the lowest

concentration used for this optimization work, leaving possibly room for

improvement);

-- Maximum or near maximum gold recoveries for the sulphide composites were

obtained at a cyanide concentration of 0.5 to 1.0 gNaCN/L;

-- Rapid gold recovery rates were achieved with leaching substantially

complete within twelve hours for most variability samples and composites

evaluated;

-- Air sparging, oxygen sparging and lead nitrate addition during

cyanidation testing did not improve gold recoveries;

-- Sulphide composites responded well to flotation treatment for recovery

of gold;

-- Gravity recoverable gold is generally liberated evenly through the grind

sizes tested;

-- Gold recovery from the cyanidation of gravity products is essentially

the same as that from the whole ore cyanidation.

Recommendations of the McClelland Metallurgical report are:

-- Further optimization of flotation conditions for the sulphide composites

is warranted as they showed high gold recoveries by flotation;

-- Further optimization of the cyanide concentration as gold recoveries did

not decrease for many oxide and sulphide samples at the lowest cyanide

concentration tested (0.5 gNaCN/L), and cyanide concentrations as low as

0.25 gNaCN/L were effective for gravity product cyanidation.

The complete metallurgical report is filed on the Company's

website at www.orezone.com.

Exploration and definition drilling

The recent drilling included a 14-hole (2,497 m) core program

that targeted Inferred blocks within the existing resource, and a

93-hole (4,581 m) RC program that tested auger drill anomalies

generated in 2012 in the area located to the SE of the current

resource.

The core drilling program returned results that were broadly in

line with the resource model and that will assist to upgrade part

of the current Inferred blocks to the Indicated category.

The RC drill program intersected narrow gold mineralization

along strike from zone 372 resulting in a possible extension of 275

m to the SE for a total strike length of at least 1,150 m. This

zone is still open-ended to the SE, and hole BRC0833 intersected

mineralization about 90 m into the footwall of zone 372 where most

of the best auger anomalies were not tested due to difficult

drilling conditions, including a shallow water table. Hole BRC0833

was stopped in mineralization and intersected 4 m at a grade of

12.6 g/t, including one meter at 43.3 g/t.

Breakdown of Drilling Meterage for this Release

----------------------------------------------------------------------------

Zone Core Drilling RC Drilling

---------------------------------------------

# of holes Total m # of holes Total m

----------------------------------------------------------------------------

Z2 11 2,066 0 0

----------------------------------------------------------------------------

Z2S 3 431 0 0

----------------------------------------------------------------------------

Z2SE 0 0 1 50

----------------------------------------------------------------------------

372 0 0 4 179

----------------------------------------------------------------------------

GBF 0 0 88 4353

----------------------------------------------------------------------------

TOTAL 14 2,497 93 4,581

----------------------------------------------------------------------------

Highlights of Core Drilling Results for this Release

--------------------------------------------------------------

Uncut Cut

From To Length Grade Grade

Zone Section Hole (m) (m) (m) (g/t) (g/t)

--------------------------------------------------------------

Z2 3550N BDD0058 101.0 103.0 2.0 6.33 5.00

--------------------------------------------------------------

Z2 3375N BDD0063 156.0 165.0 9.0 6.62 3.55

--------------------------------------------------------------

Z2 3225N BDD0065 134.0 136.0 2.0 34.91 5.00

--------------------------------------------------------------

Z2 3225N BDD0065 191.0 201.0 10.0 2.17 1.78

--------------------------------------------------------------

Z2 3025N BDD0066 169.0 175.0 6.0 2.32 2.18

--------------------------------------------------------------

Z2 2975N BDD0067 195.0 202.0 7.0 1.89 1.89

--------------------------------------------------------------

Z2 2900N BDD0068 134.5 142.0 7.5 1.58 1.58

--------------------------------------------------------------

Z22S 2400N BDD0070 135.0 151.0 16.0 2.54 2.25

--------------------------------------------------------------

Reverse Circulation ( "RC" ) Drilling Results for this

Release

--------------------------------------------------------------

Uncut Cut

From To Length Grade Grade

Zone Section Hole (m) (m) (m) (g/t) (g/t)

--------------------------------------------------------------

372 6000 BRC0830 18.00 23.00 5.00 0.63 0.63

--------------------------------------------------------------

372 6050 BRC0831 21.00 24.00 3.00 1.14 1.14

--------------------------------------------------------------

372 6100 BRC0832 18.00 23.00 5.00 1.20 1.20

--------------------------------------------------------------

372 6000 BRC0833 40.00 44.00 4.00 12.60 3.04

--------------------------------------------------------------

GBF W 5800 BRC0856 12.00 14.00 2.00 0.68 0.68

--------------------------------------------------------------

GBF W 5400 BRC0868 41.00 45.00 4.00 0.72 0.72

--------------------------------------------------------------

GBF W 5400 BRC0874 35.00 47.00 12.00 0.96 0.96

--------------------------------------------------------------

GBF W 5400 BRC0874 52.00 55.00 3.00 0.94 0.94

--------------------------------------------------------------

GBF W 5400 BRC0875 22.00 24.00 2.00 0.88 0.88

--------------------------------------------------------------

GBF W 5200 BRC0892 15.00 19.00 4.00 2.21 2.21

--------------------------------------------------------------

GBF W 5200 BRC0892 33.00 35.00 2.00 1.01 1.01

--------------------------------------------------------------

The mineralized intervals are based on a lower cut-off grade of

0.5 g/t, a minimal width of 2 m and up to a maximum of one meter of

dilution being included. Grades are weighted average of individual

assays. Cut grades use a top-cut of 5 g/t as per historical

procedures. The true width of the mineralization is approximately

70% of the drill length interval. The half-core samples were

collected by Orezone employees using a diamond saw. The core

samples were prepared by SGS Burkina Faso s.a.r.l. at the Bombore

site facility and then split by Orezone to 1 kg using Rotary Sample

Dividers (RSDs). A 1 kg aliquot was analyzed for leachable gold at

BIGS Global Burkina s.a.r.l in Ouagadougou, by bottle-roll

cyanidation using a LeachWell(TM) catalyst.

The RC drilling samples were divided by Orezone employees using

Rotary Sample Dividers (RSDs). A 2 kg split was prepared by SGS

Burkina Faso s.a.r.l. at the Bombore site facility and then split

by Orezone to 1 kg using Rotary Sample Dividers (RSDs). A 1 kg

aliquot was analyzed for leachable gold at BIGS Global Burkina

s.a.r.l in Ouagadougou, by bottle-roll cyanidation using a

LeachWell(TM) catalyst. The leach residues from all samples with a

leach grade in excess of 0.2 g/t were prepared by BIGS Global

Burkina s.a.r.l. and then split by Orezone to 50 g using Rotary

Sample Dividers (RSDs). A 50 g aliquot was analyzed by fire assay

at SGS Burkina Faso s.a.r.l.. Orezone employs a rigorous Quality

Control Program (QCP) including a minimum of 10% standards, blanks

and duplicates.

Qualified Persons

The drilling program was executed under the supervision of

Pascal Marquis, SVP Exploration for Orezone; the report titled

"Report on Metallurgical Testing - Bondi Drill Samples, MLI Job No.

3685" was prepared under the supervision of J. McPartland,

Metallurgist and VP Operations at McClelland Laboratories. All are

Qualified Persons under National Instrument 43-101 and approved

their respective technical information in this release.

About Orezone Gold Corporation

Orezone is a Canadian company with a gold discovery track record

of +12 Moz and recent mine development experience in Burkina Faso,

West Africa. The company owns a 100% interest in Bombore which is

situated 85 km east of the capital city, adjacent to an

international highway. Mineral resources are constrained within

optimized open pit shells that span 11 km, and include 4.13 Moz of

measured and indicated (125 Mt @ 1.03 g/t) and 1.03 Moz of inferred

resources (35 Mt @ 1.00 g/t) with an average depth of drilling to

only 120 meters. The Company is completing a Feasibility Study

("FS") at Bombore for a phase one oxide-only CIL plant in 2H 2013

in order to become a mid-tier gold producer.

FORWARD-LOOKING STATEMENTS AND FORWARD-LOOKING INFORMATION: This

news release contains certain "forward-looking statements" within

the meaning of applicable Canadian securities laws. Forward-looking

statements and forward-looking information are frequently

characterized by words such as "plan", "expect", "project",

"intend", "believe", "anticipate", "estimate", "potential",

"possible" and other similar words, or statements that certain

events or conditions "may", "will", "could", or "should" occur.

Forward-looking statements in this release include statements

regarding, among others; upgrading Bondi resources, improved

metallurgical recoveries, completing a FS in 2H 2013, and becoming

a mid-tier gold producer.

FORWARD-LOOKING STATEMENTS are based on certain assumptions, the

opinions and estimates of management at the date the statements are

made, and are subject to a variety of risks and uncertainties and

other factors that could cause actual events or results to differ

materially from those projected in the forward-looking statements.

These factors include the inherent risks involved in the

exploration and development of mineral properties, the

uncertainties involved in interpreting drilling results and other

geological and geotechnical data, fluctuating metal prices, the

possibility of project cost overruns or unanticipated costs and

expenses, the ability of contracted parties (including laboratories

and drill companies to provide services as contracted);

uncertainties relating to the availability and costs of financing

needed in the future and other factors. The Company undertakes no

obligation to update forward-looking statements if circumstances or

management's estimates or opinions should change. The reader is

cautioned not to place undue reliance on forward-looking

statements. Comparisons between any resource model or estimates

with the subsequent drill results are preliminary in nature and

should not be relied upon as potential qualified changes to any

future resource updates or estimates.

Readers are advised that National Instrument 43-101 of the

Canadian Securities Administrators requires that each category of

mineral reserves and mineral resources be reported separately.

Readers should refer to the annual information form of Orezone for

the year ended December 31, 2012 and other continuous disclosure

documents filed by Orezone since January 1, 2013 available at

www.sedar.com, for this detailed information, which is subject to

the qualifications and notes set forth therein.

Contacts: Orezone Gold Corporation Ron Little, CEO (613)

241-3699 Toll Free: (888) 673-0663rlittle@orezone.com Orezone Gold

Corporation Pascal Marquis, SVP Exploration (613) 241-3699 Toll

Free: (888) 673-0663pmarquis@orezone.com

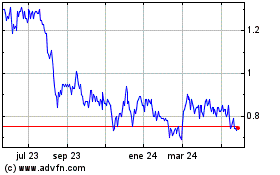

Orezone Gold (TSX:ORE)

Gráfica de Acción Histórica

De Dic 2024 a Ene 2025

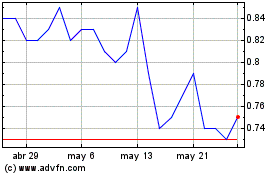

Orezone Gold (TSX:ORE)

Gráfica de Acción Histórica

De Ene 2024 a Ene 2025