- Clarins Group will deploy Dassault Systèmes’ solutions to

digitally transform the manufacturing processes of its cosmetic

products sold in 150 countries

- With the “Perfect Production” industry solution experience,

Clarins can optimize production and harmonize processes at its new

manufacturing facility in Troyes, France and its existing site near

Paris

- Improved capacity, quality and traceability will support the

company’s strategic push for operational performance and

competitive growth

Dassault Systèmes (Euronext Paris: FR0014003TT8, DSY.PA) today

announced that Clarins Group, the family-owned global cosmetics

group, has selected Dassault Systèmes’ solutions to transform its

manufacturing operations as it prepares to increase significantly

its production capacity for its portfolio of skincare, make-up, spa

and wellness products.

This press release features multimedia. View

the full release here:

https://www.businesswire.com/news/home/20240228465297/en/

Image courtesy of Clarins Group

Clarins will deploy Dassault Systèmes’ “Perfect Production”

industry solution experience based on the 3DEXPERIENCE platform.

The solution enables Clarins to leverage DELMIA Apriso applications

to streamline and improve the efficiency of manufacturing processes

at its existing production site near Paris, and at a state-of-the

art, new high environmental quality (HQE) site in Troyes, France

that is scheduled to be operational in late 2024. Dassault Systèmes

provides Clarins with a unified, flexible and powerful

manufacturing operations management solution to optimize resources,

implement best practices and harmonize processes from planning to

execution, while taking into account the specific capabilities of

each site.

“As part of its global development strategy, the Clarins Group

is building a second factory in France: a state-of-the-art plant on

two aspects, sustainable development and operational excellence.

This project follows an ambitious and comprehensive Industry 4.0

road map. To support us, we looked for a global manufacturing

solution to streamline and manage production, logistics and

maintenance, as well as synchronize warehouse materials. The

Dassault Systèmes solutions, with its extensive knowledge of our

sector, provide us with the capabilities to succeed in our

strategy,” said Denis Martin, Business Support Transformation

Officer, Clarins.

Clarins will leverage “Perfect Production” to ensure a

profitable growth of its operations while guaranteeing the quality

of its product. Nearly 400 users will rely on the solution to boost

capacity, quality and traceability by transitioning to a paperless

work environment and by gaining real-time visibility of operations

for performance monitoring and continuous improvement.

“Clarins’ choice to deploy Dassault Systèmes’ solutions to

digitally transform its manufacturing enables it to combine its 70

years of expertise in premium skincare and cosmetics with our

proven solutions that incorporate best practices from the

industry,” said Benoit Dauchin, Vice President, Consumer Packaged

Goods & Retail Industry, Dassault Systèmes. “Clarins can

increase productivity and scale its operations profitably without

compromising on the quality of the products that have made it a

globally recognized and respected innovative and responsible

brand.”

###

FOR MORE INFORMATION

Dassault Systèmes’ industry solution experiences for consumer

packaged goods and retail:

https://www.3ds.com/industries/consumer-packaged-goods-retail

Dassault Systèmes’ DELMIA Apriso applications:

https://www.3ds.com/products/delmia/apriso

Dassault Systèmes’ 3DEXPERIENCE platform, 3D design software, 3D

Digital Mock Up and Product Lifecycle Management (PLM) solutions:

http://www.3ds.com

SHARE THIS ON X, FORMERLY KNOWN AS TWITTER

Clarins teams up with @Dassault3DS to achieve new levels of

efficiency at its two French production sites #3DEXPERIENCE

Connect with Dassault Systèmes on

https://twitter.com/Dassault3DS

https://www.facebook.com/DassaultSystemes

https://www.linkedin.com/company/dassaultsystemes

https://www.youtube.com/DassaultSystemes

ABOUT DASSAULT SYSTÈMES

Dassault Systèmes, the 3DEXPERIENCE® Company, is a

catalyst for human progress. We provide business and people with

collaborative virtual environments to imagine sustainable

innovations. By creating virtual twin experiences of the real world

with our 3DEXPERIENCE platform and applications, our customers can

redefine the creation, production and life-cycle-management

processes of their offer and thus have a meaningful impact to make

the world more sustainable. The beauty of the Experience Economy is

that it is a human-centered economy for the benefit of all

–consumers, patients and citizens. Dassault Systèmes brings value

to more than 300,000 customers of all sizes, in all industries, in

more than 150 countries. For more information, visit

www.3ds.com

© Dassault Systèmes. All rights reserved. 3DEXPERIENCE, the 3DS

logo, the Compass icon, IFWE, 3DEXCITE, 3DVIA, BIOVIA, CATIA,

CENTRIC PLM, DELMIA, ENOVIA, GEOVIA, MEDIDATA, NETVIBES, OUTSCALE,

SIMULIA and SOLIDWORKS are commercial trademarks or registered

trademarks of Dassault Systèmes, a European company (Societas

Europaea) incorporated under French law, and registered with the

Versailles trade and companies registry under number 322 306 440,

or its subsidiaries in the United States and/or other

countries.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20240228465297/en/

Dassault Systèmes Press Contacts Corporate / France,

Arnaud MALHERBE, arnaud.malherbe@3ds.com, +33 (0)1 61 62 87 73

North America, Natasha LEVANTI, natasha.levanti@3ds.com, +1 (508)

449 8097 EMEA, Virginie BLINDENBERG, virginie.blindenberg@3ds.com,

+33 (0) 1 61 62 84 21 China, Grace MU, grace.mu@3ds.com, +86 10

6536 2288 India, Kriti ASHOK, kriti.ashok@3ds.com, +91 9741310607

Japan, Wen YANG, wen.yang@3ds.com, +81 3 4321 6549 Korea, Jeemin

JEONG, jeemin.jeong@3ds.com, +82 2 3271 6653

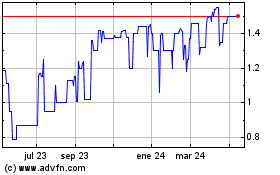

Destiny Media Technologies (TSXV:DSY)

Gráfica de Acción Histórica

De Dic 2024 a Ene 2025

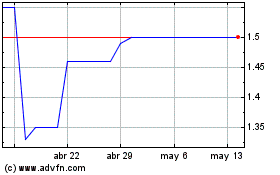

Destiny Media Technologies (TSXV:DSY)

Gráfica de Acción Histórica

De Ene 2024 a Ene 2025