Empire

Metals Limited / LON: EEE / Sector: Natural Resources

4 September 2024

Empire Metals

Limited

('Empire' or the 'Company')

Positive

Results Achieved from Initial Processing Testwork on Pitfield

Titanium Ore

Empire Metals Limited (LON:

EEE), the AIM-quoted resource exploration

and development company, is pleased to

provide an update on the mineralogical and metallurgical studies

being carried out on titanium rich ores from the

Pitfield Project in Western

Australia ('Pitfield' or the

'Project'). The Company's evaluations to date,

which incorporate both historical research and current

international knowledge and expertise, have identified a number of

highly prospective processing routes which are the focus of

on-going metallurgical testing and flowsheet development. The

testwork is being conducted at a range of independent and

government research laboratory facilities, utilising both

commercial scale equipment and reagent industry vendors. The range

of work programmes is extensive and the understanding being

generated from this breadth of work is integral to the

identification and optimisation of a preferred process flowsheet

and the development of a final product specification for the

Project.

Highlights

· Empire's metallurgical testwork

objective is to develop a processing flowsheet that will enable the

development of a fully integrated, mine to high-value titanium product facility thus achieving our

corporate goal of making Pitfield a globally significant and secure

supplier to the titanium pigment and titanium metal

industries.

· A multifaceted mineralogical and

metallurgical testwork programme has now been expanded, engaging

international and locally based expert consultants, and utilising

Australian based government and commercially owned laboratory

facilities.

· Testwork

conducted to date has been on the fresh bedrock titanite ore.

However, the discovery of concentrated, high-purity anatase in the

overlying weathered bedrock cap has shifted the testwork focus,

requiring the collection of new samples from the diamond drill core

which have now been composited and submitted to the laboratory for

crushing/grinding ahead of mineral concentration testwork.

· Titanite ore testwork has been

focused on separating the Ti-bearing minerals from the low value,

gangue minerals, a key step in the development of an economic

process flowsheet for Pitfield, with positive results achieved

during the initial gravity separation stages on the titanite-rich

fresh bedrock.

·

Preliminary sighter leach tests on titanite ore samples utilising

hydrochloric acid (HCl) have been successful with the contained

titanite mineral grains completely dissolving within 6 hours in an

atmospheric pressure HCl leach at 80 degrees Celsius.

Shaun Bunn, Managing Director, said:

"I am extremely excited by the progress being made

by our development team, led by our Process Development Manager Ms

Narelle Marriott, and well supported technically by titanium

industry specialists, Dr Trevor Nicholson and Mr Eugene Dardengo.

We have commenced research studies with CSIRO and Curtin University

scientists, both groups being located here in Western Australia,

aimed at providing important information on the nature and origin

of the mineralisation as well as the various routes through which

to extract the titanium. Through the mineralogical studies

completed to date at AXT and CSIRO (announced 22 August 2024), we

now have an increasingly detailed understanding of the

mineralisation, both for the fresh and the weathered titanium

minerals, as well as for the gangue minerals.

"We have also been working closely

with titanium industry and market consultants, TiMPC, which are

providing invaluable commercial guidance into what types of

products are most desired by the major titanium industry players

and how Empire can market its high-purity products towards the

high-value end of the market. With new knowledge being generated about

Pitfield's ore geology and the titanium industry market

requirements, plans for the next phase of testwork are being

tailored towards the development of a commercial process flowsheet

optimized for Pitfield anatase and titanite ores."

Mineralogical and

Metallurgical Update

Ore

Characterisation

Two ore types have now been identified within the

host sandstone bedrock at Pitfield: an unweathered or "primary"

titanite-rich ore type present within the fresh sandstone bedrock,

and a weathered or "secondary" anatase-rich ore type present within

the overlying, near-surface cap of weathered sandstone bedrock. The

Company's development team has initially focused on ore

characterisation in order to achieve a fundamental understanding of

the dominant primary and secondary titanium ore minerals (titanite

and anatase respectively), the nature of other associated

titanium-bearing minerals (Fe-Ti Oxides) and the principal gangue

minerals within the near-surface weathered cap (hematite, quartz

and kaolinite). In particular the ores are being characterised by

mineral percentages, the association between minerals, the mineral

grain size and mineral composition including looking for any

impurities.

Several different mineralogical analysis techniques

are being used, including TIMA analysis, XRD, SEM microprobe, and

microscope petrography. These services have been undertaken at

various independent and government owned laboratories including

Automated Mineralogy Incubator (AMI), Bureau Veritas (BV) and

Australia's national science agency, CSIRO.

CSIRO's Geoscience Drill Core Research Laboratory is

unique worldwide, offering a range of multi-disciplinary techniques

for visualising and classifying multi-element geochemical data from

drill holes, core and samples. These highly specialised techniques,

utilising equipment such as the Minalyzer and the HyLogger, will

aid the Company's geoscientists by providing rapid interpretation

of the large data volumes generated from our drilling as well as

generating key geometallurgical characteristics.

Figures 1-3. (from

clockwise) Narelle Marriott, Empire's Process Development Manager,

reviewing data from the SEM at the AMI laboratory in

Perth.

The HyLogger spectral scanner

and the Minalyzer, both located at

CSIRO's Perth laboratories.

The mineral characterisation studies have included a

wide range of samples from the exploration drilling programmes

completed to date, and include mineralised core samples from the

fresh, transition and weathered zones of bedrock intercepted in the

sampled drill holes; and also multiple large (+80 kg) composite

samples collected from the diamond drill core and crushed and

blended for metallurgical testwork.

These large diamond core composite samples will be

used to test a wide range of mineral processing and

hydrometallurgical techniques. The use of larger composite samples

is important as it allows comparison between processing methods for

testwork undertaken at multiple laboratories.

Once testwork has determined a specific flowsheet as

favourable, then additional samples will be prepared from

historical or new drilling to test ore variability, test flowsheet

variables and to produce bulk samples for engineering and

environmental studies.

Multiple programmes of work are underway, as part of

the metallurgical flowsheet development, discussed in detail below.

The programme has been designed to consider all aspects of a

flowsheet required from delivery of ore to the plant to a final

saleable product to market.

Process Flowsheet

Development

The strategy has been to consider a wide range of

high-potential mineral processing and hydrometallurgical techniques

when designing the on-going testwork programme. The process

flowsheet and related testwork considers four separate, albeit

related, components as defined in Figure 4 below.

The same testwork processes will be used to

separately test the anatase-rich secondary ore and the

titanite-rich primary ore, as the mineral assemblage (inclusive of

the gangue minerals) is entirely different as a result of the

strong, near surface weathering.

Figure 4.

Process Flowsheet components under development

Comminution

Comminution is an initial mineral processing step

aimed at breaking up the mined ore into small enough particles that

the valuable minerals are no longer in the same composite particle

as the gangue minerals. This allows the next step of mineral

concentration to happen more efficiently. Information gained

in the ore characterisation stage has guided the development of

this process flowsheet stage. Mineral grain size and mineral

association are used to determine target particle sizes. The images

from SEM and microprobe work have provided insight into the

physical occurrence of titanium bearing minerals within the

sandstone matrix, thereby focusing the testwork on equipment and

the techniques which can selectively liberate the titanium bearing

minerals without over-grinding, such as mineral sizers, scrubbers,

high pressure grinding rolls, hammer mills and stirred milling.

Standard comminution tests have already been

undertaken on samples from the fresh bedrock and the weathered zone

to provide information on rock competency and energy input for

breakage requirements. The weathered zone was confirmed to be

very soft and the fresh bedrock, whilst more competent, is expected

to fracture easily due to the bedding layers within the sandstone

sediments. Planning is underway for a full range of comminution

tests on both the weathered and fresh rocks, pending receipt of

full diamond 'PQ' drill core.

Mineral

Concentration

Testwork is ongoing at a number of commercial

laboratories for the mineral concentration of the Pitfield primary

ore samples. This programme is testing a wide range of physical and

chemical unit processes that can separate out gangue minerals from

Ti-bearing minerals. Multiple unit processes and combinations that

can be used on the Pitfield ores are being tested to determine how

best to separate the Ti-bearing minerals from the non Ti-bearing

minerals. Additionally the minerals within the non Ti-bearing

stream will be further assessed for their suitability as

potentially economic by-product streams.

As a first stage, screening and size analysis has

been undertaken to investigate the opportunity to produce a

throwaway waste stream within the comminution circuit, with the

objective of reducing the size and energy requirements of the

overall comminution circuit. Some coarse rejection of gangue

minerals was achieved and the suitability of an initial first stage

utilising scrubbing and jigs is now under consideration.

It should be noted that the majority of the testwork

conducted to date has been on composite samples produced from

primary titanite ore. With the discovery of an anatase-rich

secondary ore deposit in the near surface, weathered zone the

testwork focus has shifted to developing an understanding of the

metallurgical characteristics of the minerals within these

weathered secondary ores. This has necessitated further sampling of

the diamond core recovered from the Q1 2024 drill programme. These

samples have now been composited and submitted to the laboratory

for crushing/grinding ahead of mineral concentration testwork.

The key mineral concentration techniques currently

under investigation include:

Gravity separation

testwork is being undertaken at Allied Mineral Laboratories

(AML). AML is an independent mineral processing research facility

located in Perth, Western Australia and specialises in mineral

separation processing testwork and flowsheet design. The initial

gravity tabling tests have been focussed on producing a low-grade

mineral waste stream and a titanium-rich mineral concentrate for

further downstream processing. This research testwork is being

supported by bench scale heavy liquid separation and mineralogical

analysis to determine the optimal separation at different specific

gravities.

Early indications that the primary titanite ore will

respond well to gravity concentration are encouraging. Heavy liquid

separation at a specific gravity cut of 2.9 g/ml rejected 35% of

the mass and 46% of the gangue silicates. Only 10% of the

titanite was rejected in this stream. Further testwork on the

optimal specific gravity cut size and the liberation size to

minimise titanite losses is planned.

Magnetic separation

testwork is being undertaken at both the Bureau Veritas (BV)

mineral laboratory and at Longi, who is a leading manufacturer of

industrial magnetic separation equipment. The research

testwork underway is focused on separating weakly magnetic

minerals, like ilmenite, from non-magnetic minerals such as quartz

or hematite.

Froth Flotation

testwork is being undertaken at both ALS Metallurgy and

Arnofio Flotation Services. Both flotation laboratories bring a

wide range of experience in froth flotation techniques. To date,

the Company has completed over 60 diagnostic flotation tests,

investigating a range of physical conditions and flotation

chemicals.

Figures 5-8

(clockwise from top left) : crushed primary titanite ore prepared

for testwork programmes, Empire Metals' Process Development Manager

observing flotation testwork, close up of a flotation test, gravity

table test in progress and the Longi laboratory scale WHIMS

magnetic separation unit.

Hydrometallurgy

Hydrometallurgical processing, commonly referred to

as leaching, is the process whereby the mineral particles are

partially dissolved and the elements of interest are separated from

other impurities present.

A number of different approaches to this stage of the

process flowsheet have been identified from published research,

standard industrial practice and existing leaching operations.

Bench-scale testwork is determining the leach response of both the

titanium ore minerals and the associated gangue minerals, initially

focused on bringing the titanium into solution, and then looking to

optimise the leach solution chemistry and define the process steps

for product finishing. The testwork is assessing acid types (HCl

and H2SO4) and their consumption, options for

reagent recycling, impurity management and options for producing a

final high-purity titanium product.

Leaching options include a range of temperatures,

under either atmospheric or low pressure leaching conditions.

Previous research on leaching titanite ores indicated that either

sulphuric or hydrochloric acid can be effective. Preliminary

sighter leach tests on Pitfield primary titanite ore samples have

now been completed with positive results. Titanite was shown to

completely dissolve within 6 hours in a concentrated HCl leach at

80 degrees C. Further testwork will be undertaken on the mineral

concentrates generated from the gravity and/or flotation testwork

programmes.

The quality of the concentrates produced in the

mineral separation/concentration step will affect the performance

of the subsequent leaching step. As such, both testwork programmes

will require a feedback loop so that there is the opportunity to

optimise the mineral concentrate quality in order to improve the

outcomes of the titanium extraction step.

Product

Finishing

A high-grade, high-purity titanium dioxide product

suitable as feedstock for chloride pigment production or conversion

into titanium metal sponge, has been identified as the most

desirable final product for the project. The possible process

chemistries in the leaching step provide a good synergy with this

type of final product. The potential optionality to produce a range

of different products, depending on market demand, will be

investigated in the testwork programme. Additionally, any

opportunity to produce a viable by-product and to reduce waste

streams is being explored.

Flowsheet

Design

The extensive range of testwork programmes currently

underway form an important screening process which will help shape

the next phase of research testwork. From these results an in-depth

understanding of the ore is being obtained that will guide the next

phases of testwork and consequently the process flowsheet design.

Results so far have shown a high potential for a multi-stage

mineral separation process flowsheet, likely to include both

gravity and flotation unit processes. A further mineral extraction

processing step using hydrometallurgical leaching techniques is

likely to form the back end of the process flowsheet and allow for

production of a high-grade, high-purity titanium dioxide product.

Testwork is well advanced on the primary titanite ore samples and a

parallel testwork programme is now underway on the secondary

anatase ore.

The Pitfield

Project

Located within the Mid-West region of Western

Australia, near the northern wheatbelt town of Three Springs,

Pitfield lies 313km north of Perth and 156km south of Geraldton,

the Mid West region's capital and major port. Western Australia is

ranked as one of the top mining jurisdictions in the world

according to the Fraser Institute's Investment Attractiveness Index

published in 2023, and has mining-friendly policies, stable

government, transparency, and advanced technology expertise.

Pitfield has existing connections to port (both road & rail),

HV power substations, and is nearby to natural gas pipelines as

well as a green energy hydrogen fuel hub, which is under planning

and development (refer Figure 9).

Figure 9. Pitfield Project Location showing the

Mid-West Region

Infrastructure and Services.

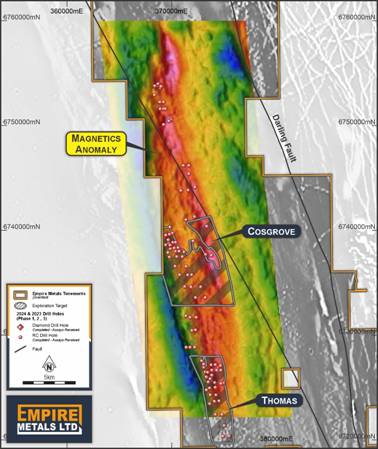

Since commencing its maiden drill

campaign in March 2023, the Company has completed a total of 107

drillholes for 17,003m (including seven diamond core holes for

2,025m), of which 67 RC drillholes and six diamond core drillholes

were drilled within the Cosgrove and Thomas prospects (Figure 10).

The drilling shows a high-grade (>5% TiO2), more than

1km wide central core running on a north-south trend through both

mineral prospects, which could join between the two prospects

thereby representing a potential total strike length of more than

20km. Significantly, the RC drillhole results clearly indicate

elevated TiO2 grades are present within the top 40m

(RNS: 15 May 2024).

Figure 10. Grey-scale magnetics map overlain

by airborne gravity survey results with the location of RC and

Diamond Core drillholes and the Cosgrove and Thomas Exploration

Target.

Market Abuse Regulation (MAR)

Disclosure

Certain information contained in

this announcement would have been deemed inside information for the

purposes of Article 7 of Regulation (EU) No 596/2014, as

incorporated into UK law by the European Union (Withdrawal) Act

2018, until the release of this announcement.

**ENDS**

For further information please visit www.empiremetals.co.uk or

contact:

|

Empire Metals Ltd

Shaun Bunn / Greg Kuenzel /

Arabella Burwell

|

Tel: 020 4583 1440

|

|

S. P. Angel Corporate Finance LLP (Nomad &

Broker)

Ewan Leggat / Adam Cowl

|

Tel: 020 3470 0470

|

|

Shard Capital Partners LLP (Joint

Broker)

Damon Heath

|

Tel: 020 7186 9950

|

|

St Brides

Partners Ltd (Financial

PR)

Susie

Geliher / Charlotte Page

|

Tel: 020

7236 1177

|

About Empire Metals

Limited

Empire Metals is an AIM-listed

exploration and resource development company (LON: EEE) with a

primary focus on developing Pitfield, an emerging giant titanium

project in Western Australia.

Exploration activity at Pitfield has

confirmed the discovery of a new giant mineralised system extending

over 40km by 8km by 5km deep. Drilling campaigns have confirmed

high-grade TiO₂ mineralised zones across thick bedded intervals to

a vertical depth of ~350m, confirming Pitfield as a world class,

district-scale titanium mineral system.

Empire is now accelerating the

economic development of Pitfield, with the objective of becoming a

leading producer of high value titanium dioxide

products.

The Company also has two further

exploration projects in Australia; the Eclipse Project and the

Walton Project in Western Australia, in addition to three precious

metals projects located in a historically high-grade gold producing

region of Austria.