TIDMCOBR

RNS Number : 9124L

Cobra Resources PLC

11 September 2023

THIS ANNOUNCEMENT CONTAINS INSIDE INFORMATION FOR THE PURPOSES

OF ARTICLE 7 OF REGULATION 2014/596/EU WHICH IS PART OF DOMESTIC UK

LAW PURSUANT TO THE MARKET ABUSE (AMMENT) (EU EXIT) REGULATIONS (SI

2019/310) ("UK MAR"). UPON THE PUBLICATION OF THIS ANNOUNCEMENT,

THIS INSIDE INFORMATION (AS DEFINED IN UK MAR) IS NOW CONSIDERED TO

BE IN THE PUBLIC DOMAIN.

NOT FOR RELEASE, PUBLICATION OR DISTRIBUTION, IN WHOLE OR IN

PART, DIRECTLY OR INDIRECTLY IN OR INTO THE UNITED STATES,

AUSTRALIA, CANADA, JAPAN, THE REPUBLIC OF SOUTH AFRICA OR ANY OTHER

JURISDICTION WHERE TO DO SO WOULD CONSTITUTE A VIOLATION OF THE

RELEVANT LAWS OF SUCH JURISDICTION.

11 September 2023

Cobra Resources plc

("Cobra" or the "Company")

Positive Metallurgy Confirms Ionic Rare Earth Mineralisation at

Boland Prospect, Wudinna

&

New Tenement Applications to Increase Project Size

Cobra's Geological Concept Has Capacity to Change Future Supply

of Critical REEs to Drive Decarbonisation

Cobra, a gold, rare earth and IOCG exploration company focused

on the Wudinna Project in South Australia, is pleased to advise

that metallurgical testwork carried out by the Australian Nuclear

Science and Technology Organisation ("ANSTO") confirms Rare Earth

Elements ("REE") mineralisation at the Boland palaeo-channel

prospect to be cost-efficient, easily recoverable ionic adsorption

rare earth clays.

Cobra can now attest to having highly desirable ionic rare earth

mineralisation at Wudinna, where extraction is low-cost and yields

high recoveries of heavy and magnet rare earths which the Company

believes to be regionally scalable.

Accordingly, the Company has made two further applications west

of the Wudinna Project to establish itself as the dominant

landholder on the Narlaby palaeo-channel.

Highlights

-- Ionic metallurgy : testing by ANSTO demonstrates rapid

recoveries by desorption leaching within 30 minutes using ammonium

sulphate in weak acid conditions (pH4), with low acid consumption

and low dissolution of gangue elements, where:

o Further increases in REE recovery are demonstrated through

increased leach time (six hours) and a slight increase in acidity

(pH3) where maximum extractions of 58% Magnet Rare Earth Oxides

("MREOs") and 65% Heavy Rare Earth Oxides ("HREOs") were

achieved

o Low acid consumption of 6-30 kg/t supports very positive

economic metrics for further processing optimisation

o Low rates of dissolution of gangue elements (aluminium,

calcium, iron, thorium and uranium)

-- Preferred mineralogy : ionic clay REE deposits are a superior

source of HREOs and MREOs (neodymium, praseodymium, dysprosium and

terbium), owing to their enrichment relative to Light Rare Earth

Oxides ("LREOs") and their ability to be desorbed through ion

exchange rather than aggressively baked and acid leached which is

high cost and increases environmental risk

-- Superior ratios of recovery: high recoveries of high-value

HREOs and lower recoveries of low-value LREOs that enable the

cost-effective generation of a superior REE carbonate product

-- New concept for ionic mineralisation : the Boland prospect

presents as a new alternate source of low disturbance, low-cost

MREOs and HREOs owing to its amenability to Insitu Recovery Mining

("ISR") and cost-effective metallurgy

-- Significant scalability : over 430 km(2) of untested

palaeo-channel has been defined over the existing Wudinna Project

tenements. These results confirm "proof-of-concept" and are

game-changing for future REE expansion drilling

-- Expanded footprint : a further two tenement applications

(Figure 1) have been submitted by Lady Alice Mines Pty Ltd (a Cobra

subsidiary) to add a further 1,512 km(2) of prospective

palaeo-channel geology making Cobra the dominant holder of

palaeo-channel ground in the region

-- Forward plan : to rapidly advance the Boland discovery, the Company plans to:

o Drill sonic core holes to better understand the nature of

mineralisation, define permeability potential, and recover

sufficient samples to produce a REE carbonate

o Install monitoring wells to gather baseline hydrology data to

inform pilot ISR extraction tests

o Resource expansion Aircore ("AC") drilling to define a maiden

ionic REE resource

o Re-analysis of historic drill samples on new tenement

applications to define new ionic REE occurrences

o Regional AC palaeo-channel testing to demonstrate province

scale potential

Rupert Verco, CEO of Cobra, commented :

"These metallurgy results place the Company amongst the handful

of projects which can attest to having highly desirable ionic rare

earth mineralisation.

Low-cost metallurgy, coupled with low-cost insitu recovery

mining, are the key ingredients to enable a clean, low-impact

sustainable source of rare earth metals.

The REE mineralisation at Boland can be rapidly recovered using

a lixiviant comparable to orange juice in acidity, in a mining

practice that can be integrated into current agricultural land

practices.

It is these attributes that make this discovery significant. The

Boland discovery has the right technical components to secure the

future supply of critical rare earth metals necessary to

decarbonise the western world.

With the further two exploration licence applications, Cobra is

now the dominant holder of REE prospective palaeo-channel in the

region, a jurisdiction experienced in, and supportive of, insitu

recovery mining."

David Clarke, Non-Executive Director of Cobra, commented :

"The proof-of-concept Cobra has delivered at Boland is the

result of exceptional geological thinking from Rupert Verco and

Robert Blythman whom I congratulate on behalf of the Board. It was

a strongly reasoned concept but nothing like this model has

previously existed. It may take some time for the full implications

of Cobra's model to be apparent - but it is already clear that it

is positive for Cobra's shareholders and the western world's ready

access to a range of critical rare earth metals required for

permanent magnets that are the efficiency enabler for

electrification."

Boland Background

AC drilling in April at the Boland prospect was designed for

"proof-of-concept" to confirm the mobilisation of REEs from

enriched saprolites to the younger clays hosted within the

palaeo-channel system.

A total of 17 holes were drilled across a broad area

representing 12 km(2) , and drilling produced multiple

intersections, where:

-- Smectite clays hosted within palaeo-channel sands and basal

clays in contact with saprolite are enriched in HREOs

-- Intersections extended into underlying saprolite where

elevated grades are depleted in heavy rare earths in comparison to

overlying smectite clays

-- Intersections in palaeo-channel clays up to 3m at 1,004 ppm

Total Rare Earth Oxide ("TREO") and up to 42m at 2,189 ppm TREO in

underlying saprolite

A total of 17 representative 3m composite samples from the

Boland prospect were submitted to ANSTO for desorption

metallurgical testing (see Table 1). Samples are characterised by

three geological domains:

1. Smectite playa clays (five samples)

2. Contacting palaeo-channel saprolite (five samples)

3. Underlying saprolite (seven samples)

Metallurgical Results

Results show rapid recoveries by desorption of REEs in the first

30 minutes using 0.5 mol ammonium sulphate as a lixiviant, at

ambient temperatures and weak acidic conditions (see Table 1).

The highest recoveries are observed from domain 1 (playa clays

hosted within the palaeo-channel) and domain 2 (contacting

palaeo-channel saprolite), where mineralisation is interpreted to

ionically bind to smectite clays at the contact with channel sands,

where ionic adsorption is driven by discrete changes in

acidity/alkalinity.

An important characteristic of ionic clay hosted rare earths is

the low acid consumption (results average 6-30 kg/t) and the low

dissolution of gangue minerals including cerium, aluminium, calcium

and iron. Additionally, the dissolution of uranium and thorium is

low.

Increases in REE recovery were achieved by increasing the leach

time to six hours (pH4) and lowering the acidity to pH3 over a

leach time of up to six hours (see Table 1).

Within the palaeo-channel, maximum recoveries at pH3 (six hours)

are 58% for MREOs and 65% for HREOs (see Figure 3). These results

are considered highly encouraging with scope for increased

recoveries with optimised sample compositing and increased

understanding of REE clay adsorption distribution and

mineralogy.

Pleasingly, samples of saprolite in contact with the

palaeo-channel exhibit low-moderate extractions under desorption

conditions (see Figure 4).

In contrast, saprolite samples show low <10% recoveries and

higher acid consumptions than palaeo-channel sediments under

desorption conditions.

Figure 1: Composite LAM9170 exhibits high recoveries of MREOs

and HREOs under desorption conditions

Figure 2: Individual REE recoveries from LAM9170 composite under

tested desorption conditions

Figure 3 : Average recoveries and acid consumption of the five

playa clay sample composites

Figure 4 : Average recoveries and acid consumption of the five

saprolite sample composites in contact with palaeo-channel

sediments

Figure 5: Locality plan highlighting the Company's exploration

tenement applications on the Narlaby palaeo-channel

About Insitu Recovery Mining

ISR is a highly cost-effective method of mining that involves

recovering the ore where it is in the ground, and recovering

minerals from it by dissolving them and pumping pregnant solutions

to the surface where the minerals can be recovered. This is

achieved owing to aquifer permeability and applied in a manner to

ensure that mining solutions do not contaminate groundwater away

from the orebody. Once ore extraction is complete, aquifers are

returned to their natural chemistry by neutralising mining

solutions. This style of mining is cost-effective, low in

environmental impact on aquifers and surfaces.

Owing to the interbedded nature of mineralised clay beds and

permeable sand layers at Boland, and the fast extractions achieved

through REE desorption, it is believed that ISR mining could be

integrated with current land-uses considerate and adaptable to

farming, conservation and indigenous heritage.

South Australia is the leading state in Australia for insitu

recovery mining where it is actively endorsed, actively governed

and successfully implemented.

Figure 6 : Conceptual ISR process for REE extraction at

Boland

Next Steps

Cobra will now aim to capitalise on the significance of these

results from the Boland prospect and commence a scope of work that

includes:

-- Mineralogical and insitu recovery studies - drilling of 3-5 core holes to:

o Determine the distribution of REEs within clay bands

o Identify parameters for future insitu recovery testing

o Define appropriate future composite sample lengths

o Enable advancement of metallurgical testing to ultimately

produce a REE carbonate for commercial marketing

-- Monitoring well installation - to enable baseline monitoring and analysis of aquifers

-- Resource drilling - AC drilling aimed at expanding the

footprint of Ionic REE mineralisation at the Boland prospect

-- Maiden Boland Mineral Resource Estimate ("MRE")

-- Regional palaeo-channel testing - AC drilling testing the

concept within the Corrobinnie palaeo-channel at the Wudinna

Project

-- Sample re-analysis and maiden AC drilling to test

palaeo-channel targets on other 100% owned Cobra tenements

-- Further metallurgical testing to optimise recoveries and test further zones of mineralisation

Enquiries:

Cobra Resources plc via Vigo Consulting

Rupert Verco (Australia) +44 (0)20 7390 0234

Dan Maling (UK)

SI Capital Limited (Joint Broker)

Nick Emerson

Sam Lomanto

+44 (0)1483 413 500

Shard Capital Partners LLP (Joint

Broker)

Erik Woolgar

Damon Heath +44 (0)20 71869952

Vigo Consulting (Financial Public

Relations)

Ben Simons

Kendall Hill +44 (0)20 7390 0234

The person who arranged for the release of this announcement was

Rupert Verco, Managing Director of the Company.

About Cobra

Cobra is defining a unique multi-mineral resource at the Wudinna

Project in South Australia's Gawler Craton, a tier one mining and

exploration jurisdiction which hosts several world-class mines.

Cobra's Wudinna tenements totalling 1,832 km(2) , and other nearby

tenement rights totalling 1,429 km(2) , contain highly desirable

and ionic rare earth mineralisation, amenable to low-cost, low

impact insitu recovery mining, and critical to global

decarbonisation.

Cobra's Wudinna tenements also contain extensive orogenic gold

mineralisation and are characterised by potentially open-pitable,

high-grade gold intersections, with ready access to infrastructure.

Cobra has 22 orogenic gold targets outside of the current 279,000

Oz gold JORC Mineral Resource Estimate.

Follow us on social media:

LinkedIn: https://www.linkedin.com/company/cobraresourcesplc

Twitter: https://twitter.com/Cobra_Resources

Subscribe to our news alert service:

https://cobraplc.com/news/

Competent Persons Statement

Information in this announcement has been assessed by Mr Luke

Stannard, a Fellow of the Australasian Institute of Mining and

Metallurgy ("FAusIMM"). Mr Stannard is a Consultant to Cobra

Resources Plc and has sufficient relevant experience in the type of

extraction process which he is undertaking to qualify as a

Competent person as defined in the 2012 Edition of the Australasian

Code for Reporting Exploration Results, Mineral Resources and Ore

Reserves (the "JORC" Code). This includes 7 years of leaching

extraction.

Information in this announcement has been assessed by Mr Rupert

Verco, a Fellow of the Australasian Institute of Mining and

Metallurgy ("FAusIMM"). Mr Verco an employee of Cobra Resources Plc

has more than 16 years relevant industry experience, which is

relevant to the style of mineralisation, deposit type and to the

activity which he is undertaking to qualify as a Competent Person

as defined in the 2012 Edition of the Australasian Code for

Reporting Exploration Results, Mineral Resources and Ore Reserves

(the "JORC" Code). This includes 11 years of Mining, Resource

Estimation and Exploration

Information in this announcement relates to exploration results

that have been reported in the following announcements:

-- "Maiden Rare Earth Resource Estimate - Unique and Unconstrained" dated 9 January 2023

-- "Drilling Defines REE Resource Extension Potential" dated 12 June 2023

-- "Exception REE Results at Boland" dated 20 June 2023

Definitions

REO - Rare Earth Oxides

TREO - Total Rare Earth Oxides plus yttrium

MREO - Magnet Rare Earth Oxide (Nd(2) O(3) + Pr(6) O(11) + Dy(2)

O(3) + Tb(2) O(3) )

HREO - Heavy Rare Earth Oxides

LREO - Light Rare Earth Oxides

MRE - Mineral Resource Estimate

Cobra's REE Strategy

The economic viability of clay hosted REEs is more dependent

upon low mining and processing costs, a consequence of mineralogy

rather than grade. On this basis, the Company has focused on:

1. REE resource expansion aimed at growing its complementary

dual gold and REE resources, where the spatial proximity of REE

mineralisation to gold enables cost efficient, value add

potential

2. Targeting low cost, easily extractable ionic clay hosted

mineralisation by defining and targeting conditions that promote

ionic mineralisation. The Boland prospect was defined on the basis

of chemical and geological conditions that promote the mobility and

adsorption of ionic REEs. These metallurgy results at Boland have

provided proof of concept and provide an excellent foundation for

positive economics

Further Information Regarding the Boland Metallurgy Results

Ionic clay adsorption REE mineralisation is the industry

preferred style of rare earth mineralisation owing to its ability

to be desorbed from clay particles under relatively benign

acidities, with superior ratios of high-value REEs. In general,

weaker acids (higher acidities) are more cost effective to produce,

less environmentally harmful and operationally safer to manage. As

a consequence of the desorption process, extractions occur quickly

(minutes to hours) and at ambient temperatures making REE recovery

most economically competitive.

Since the prospectivity of REEs at the Wudinna Project was

identified in late 2021, the Company has taken a technical approach

in understanding the enrichment, mobility, and mineralogy of REE

occurrences within clay saprolite and tertiary and quaternary aged

clays across the Company's 3,261 km(2) land tenure.

The identification of REE depletion within the saprolite above

and proximal to the 104,000 Oz Barns gold resource, led the Company

to theorise that the highly acidic conditions (pH<2) contribute

to the re-mobilisation of REEs away from the Barns gold resource

and the sulphide rich Hiltaba granites. The Boland prospect is

considered to host the right conditions to promote ionic adsorption

of mobilised REEs and therefore act as a 'trap' for fluid mobile

REEs. These metallurgical results are a proof of concept confirming

desorption of REEs from palaeo-channel clays.

ANSTO is a world leader in REE metallurgy and the development in

REE metallurgical flowsheets. Diagnostic testing parameters

included:

-- 0.5 M (NH4)2SO4 as lixiviant

-- pH 4; pH3

-- pH 4: 0.5 h & 6 h, pH3: 0.5 h, 2 h & 6 h

-- Ambient temperature (22 deg C)

-- 4 wt% solids density

-- Acidity maintained through the addition of H2SO4

Metallurgical results demonstrate:

-- Desorption is greatest within Eocene age clays

-- Recoveries increase with time and increasing acidity

-- HREOs are recovered in greater ratios than LREOs

-- Moderate desorption times are interpreted to be a consequence

of sample composite dilution. Faster desorption rates are likely

with refined sample compositing

Table 1 : Average recoveries of playa clays (five samples) and

contacting saprolite (five samples)

REO Playa Clays Contacting Saprolite

------------------

pH4 pH4

pH4 6hrs pH3 pH3 pH3 pH4 6hrs pH3 pH3 pH3

------------------

0.5hrs 6hrs 0.5hrs 2hrs 6hrs 0.5hrs 6hrs 0.5hrs 2hrs 6hrs

------------------ ------- ------ ------- ----- ----- ------- ------ ------- ----- -----

La(2)

O(3) 11 15 17 19 22 3 5 4 5 5

CeO(2) 17 22 25 26 30 4 7 6 6 7

Pr(6)

O(11) 18 22 27 29 33 5 8 7 8 9

Nd(2)

O(3) 21 27 33 35 38 7 11 10 11 13

Sm(2)

O(3) 25 31 39 43 46 9 13 13 17 18

Eu(2)

O(3) 24 36 44 48 49 16 15 22 25 25

Gd(2)

O(3) 25 37 43 46 49 14 19 22 24 27

Tb(4)

O(7) 26 36 42 44 49 22 21 27 27 27

Dy(2)

O(3) 28 40 45 48 51 14 16 18 22 25

Ho2O3 29 37 39 41 47 25 20 26 27 27

Er(2)

O(3) 26 37 43 45 50 10 14 18 20 22

Tm(2)

O(3) 35 35 40 40 46 - - - - -

Yb(2)

O(3) 22 32 37 42 44 8 11 14 14 14

Lu(2)

O(3) 29 34 35 35 35 - - - - -

Y(2) O(3) 26 34 37 39 43 17 18 24 28 29

LRE 16 21 24 26 29 4 6 6 6 7

HRE 26 35 41 44 47 10 13 15 18 20

MRE 21 27 33 35 38 7 10 9 11 12

TREY-Ce 19 25 29 31 35 6 9 8 9 10

------- ------ ------- ----- ----- ------- ------ ------- ----- -----

Acid Consumption

kg/t 12 14 17 21 25 9 13 16 24 33

------- ------ ------- ----- ----- ------- ------ ------- ----- -----

Significant intersections from maiden Boland AC drilling

include:

-- CBAC0164: 3m at 942 ppm TREO (22% MREO) from 15m (playa

clay), and 3m at 1,333 ppm TREO (13% MREO) from 30m (playa clay)

and 42m at 2,189 ppm TREO (25% MREO) from 36m (saprolite clay)

-- CBAC0163: 3m at 559 ppm TREO (24% MREO) from 18m (playa

clay), and 3m at 618 ppm TREO (22% MREO) from 21m (playa clay) and

12m at 1,191 ppm TREO (27% MREO) from 36m (saprolite clay)

-- CBAC0168: 12m at 948 ppm TREO (19% MREO) from 42m (saprolite clay)

-- CBAC0176: 3m at 516 ppm TREO (23% MREO) from 27m (playa clay)

and 3m at 661 ppm TREO (19% MREO) from 48m (contact saprolite clay)

and 1,984 ppm TREO (22% MREO) from 54m (saprolite clay)

-- CBAC0175: 3m at 429 ppm TREO (23% MREO) from 27m (playa clay)

-- CBAC0172: 3m at 685 ppm TREO (20% MREO) from 54m (saprolite clay)

-- CBAC0177: 3m at 545 ppm TREO (26% MREO) from 42m (saprolite clay) to EOH

-- CBAC0162: 6m at 437 ppm TREO (24% MREO) from 42m (playa clay)

Figure 7 : Overview of AC drilling results and metallurgical

recoveries at the Boland prospect

Table 2 : Lithium borate fusion assays of composite samples

submitted for metallurgical testing

HoleID SampleID Geological La2O3 CeO2 Pr6O11 Nd2O3 Sm2O3 Eu2O3 Gd2O3 Tb4O7 Dy2O3 Ho2O3 Er2O3 Tm2O3 Yb2O3 Lu2O3 Y2O3 TREO+Y LREO HREO MREO

domain

ppm ppm ppm ppm ppm ppm ppm ppm ppm ppm ppm ppm ppm ppm ppm ppm ppm ppm ppm

Playa

CBAC0163 LAM9165 Clay 100 267 27 95 16 3 11 2 9 2 4 1 4 1 38 579 488 52 132

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

Playa

CBAC0163 LAM9168 Clay 116 286 30 110 18 3 16 2 14 3 7 1 6 1 74 688 542 72 156

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

Playa

CBAC0163 LAM9170 Clay 110 150 20 65 13 2 12 2 11 2 7 1 6 1 65 468 345 57 98

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

Playa

CBAC0164 LAM9184 Clay 177 434 45 162 29 5 23 3 19 3 9 1 8 1 83 1,004 817 103 230

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

Playa

CBAC0176 LAM9381 Clay 103 230 24 83 15 3 12 2 10 2 5 1 5 1 51 548 441 56 120

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

Cont

CBAC0163 LAM9173 Sap 225 230 39 107 12 2 7 1 5 1 3 0 3 1 28 665 601 35 152

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

Cont

CBAC0163 LAM9174 Sap 320 378 60 192 22 3 12 1 8 1 4 1 4 1 38 1,046 951 57 262

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

Cont

CBAC0164 LAM9188 Sap 107 137 11 26 3 1 3 1 4 1 3 1 4 1 31 332 281 20 42

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

Cont

CBAC0164 LAM9189 Sap 480 649 51 118 12 1 6 1 3 1 2 0.2 2 0 25 1,350 1,297 28 173

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

Cont

CBAC0176 LAM9390 Sap 82 378 24 90 18 2 15 2 11 2 4 1 3 0 43 675 574 57 126

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

CBAC0163 LAM9175 Saprolite 522 694 103 322 40 5 20 2 11 2 5 1 4 1 51 1,782 1,641 90 438

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

CBAC0164 LAM9192 Saprolite 557 876 113 363 45 6 24 2 12 2 5 1 4 1 49 2,060 1,909 102 490

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

CBAC0164 LAM9193 Saprolite 545 721 112 359 46 6 22 2 11 2 5 1 5 1 51 1,890 1,737 101 484

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

CBAC0164 LAM9194 Saprolite 446 437 88 279 36 5 18 2 9 2 4 1 4 1 42 1,372 1,250 80 378

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

CBAC0164 LAM9195 Saprolite 589 954 140 486 65 9 33 4 16 3 6 1 6 1 63 2,376 2,170 143 646

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

CBAC0163 LAM9176 Saprolite 418 747 83 271 34 5 18 2 10 2 5 1 4 1 48 1,645 1,518 79 365

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

CBAC0176 LAM9393 Saprolite 427 927 93 323 42 7 25 3 14 3 7 1 6 1 83 1,963 1,770 109 433

---------- ------------ ------ ----- ------- ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ----- ------- ------ ----- -----

Appendix 1: JORC Code, 2012 Edition - Table 1

Section 1 Sampling Techniques and Data

Criteria JORC Code explanation Commentary

Sampling Pre 2021

techniques * Nature and quality of sampling (eg cut channels, * Historic RC and RAB drilling methods have been

random chips, or specific specialised industry employed at Clarke and Baggy Green Prospects since

standard measurement tools appropriate to the 2000.

minerals under investigation, such as down hole gamma

sondes, or handheld XRF instruments, etc). These

examples should not be taken as limiting the broad * Pulp samples from pre-Cobra Resources' drilling were

meaning of sampling. collected with intervals of 1-6 m. Samples were

riffle split if dry or sub split using a trowel if

wet.

* Include reference to measures taken to ensure sample

representivity and the appropriate calibration of any

measurement tools or systems used. * Pulp samples were obtained from Challenger geological

services using a combination of logging and

geochemical selection criteria. Samples pulled from

* Aspects of the determination of mineralisation that storage were re-pulverised at the laboratory prior to

are Material to the Public Report. further analysis.

* In cases where 'industry standard' work has been done 2021 - 2022

this would be relatively simple (eg 'reverse * Sampling during Cobra Resources 2022 aircore ("AC")

circulation drilling was used to obtain 1 m samples drilling programme at all Prospects were obtained

from which 3 kg was pulverised to produce a 30 g through AC drilling methods.

charge for fire assay'). In other cases more

explanation may be required, such as where there is

coarse gold that has inherent sampling problems. * 2 m samples were collected in 20l buckets via a rig

Unusual commodities or mineralisation types (eg mounted cyclone. An aluminum scoop was used to

submarine nodules) may warrant disclosure of detailed collect a 2-4 kg sub sample from each bucket. Samples

information. were taken from the point of collar, but only samples

from the commencement of saprolite were selected for

analysis.

* Samples submitted to the Genalysis Intertek

Laboratories, Adelaide and pulverised to produce the

25g fire assay charge and 4 acid digest sample.

* A summary of previous RC drilling at the Wudinna

Project is outlined in the Cobra Resources' RNS

number 7923A from 7 February 2022.

2023

RC

* Samples were collected via a Metzke cone splitter

mounted to the cyclone. 1m samples were managed

through chute and butterfly valve to produce a 2-4 kg

sample. Samples were taken from the point of collar,

but only samples from the commencement of saprolite

were selected for analysis.

* Samples submitted to Bureau Veritas Laboratories,

Adelaide, and pulverised to produce the 50 g fire

assay charge and 4 acid digest sample.

AC

* A combination of 2m and 3 m samples were collected in

green bags via a rig mounted cyclone. An PVC spear

was used to collect a 2-4 kg sub sample from each

green bag. Samples were taken from the point of

collar.

* Samples submitted to Bureau Veritas Laboratories,

Adelaide, and pulverised to produce the 50 g fire

assay charge and 4 acid digest sample.

============================================================ =======================================================================

Drilling Pre 2021

techniques * Drill type (eg core, reverse circulation, open-hole * Drill methods include AC, RH and RAB in

hammer, rotary air blast, auger, Bangka, sonic, etc) unconsolidated regolith and aircore hammer in hard

and details (eg core diameter, triple or standard rock. Some shallow RC holes have been drilled in

tube, depth of diamond tails, face-sampling bit or place of AC and RAB, a single diamond drillhole has

other type, whether core is oriented and if so, by been incorporated in the estimate.

what method, etc).

2021- 2022

* Drilling completed by McLeod Drilling Pty Ltd using

75.7 mm NQ air core drilling techniques from an ALMET

Aircore rig mounted on a Toyota Landcruiser 6x6 and a

200psi, 400cfm Sullair compressor.

* Slimline RC drilling was completed by Wuzdrill pty

limited and Indicator drilling services Pty Ltd using

a 400D and Mantis C60R drill rigs using a 4" hammer

and 78mm drill rods.

2023

* Drilling completed by Bullion Drilling Pty Ltd using

5 3/4 " reverse circulation drilling techniques from

a Schramm T685WS rig with an auxiliary compressor.

* Drilling completed by McLeod Drilling Pty Ltd using

75.7 mm NQ air core drilling techniques from an ALMET

Aircore rig mounted on a Toyota Landcruiser 6x6 and a

200psi, 400cfm Sullair compressor.

============================================================ =======================================================================

Drill sample

recovery * Method of recording and assessing core and chip * Sample recovery was generally good.All samples were

sample recoveries and results assessed. recorded for sample type, quality and contamination

potential and entered within a sample log.

* Measures taken to maximise sample recovery and ensure

representative nature of the samples. * In general, sample recoveries were good with 10 kg

for each 1 m interval being recovered from AC

drilling.

* Whether a relationship exists between sample recovery

and grade and whether sample bias may have occurred

due to preferential loss/gain of fine/coarse * No relationships between sample recovery and grade

material. have been identified.

* R C d rilling completed by Bullion Drilling Pty Ltd

using 5 3/4 " reverse circulation drilling techniques

from a Schramm T685WS rig with an auxiliary

compressor

* Sample recovery f or RC was generally good. All

samples were recorded for sample type, quality and

contamination potential and entered within a sample

log.

* In general, R C sample recoveries were good with

35-50 kg for each 1 m interval being recovered.

* No relationships between sample recovery and grade

have been identified.

============================================================ =======================================================================

Logging

* Whether core and chip samples have been geologically * All drill samples were logged by an experienced

and geotechnically logged to a level of detail to geologist at the time of drilling. Lithology, colour,

support appropriate Mineral Resource estimation, weathering and moisture were documented.

mining studies and metallurgical studies.

* Logging is generally qualitative in nature.

* Whether logging is qualitative or quantitative in

nature. Core (or costean, channel, etc) photography.

* All drill metres have been geologically logged on s

ample intervals (1-3 m) .

* The total length and percentage of the relevant

intersections logged.

============================================================ =======================================================================

Sub-sampling Pre-2021

techniques * If core, whether cut or sawn and whether quarter, * Samples from AC, RAB and "bedrock" RC holes have been

and sample half or all core taken. collected initially as 6 m composites followed by 1 m

preparation re-splits. Many of the 1 m re-splits have been

collected by riffle splitting.

* If non-core, whether riffled, tube sampled, rotary

split, etc and whether sampled wet or dry.

* RC samples have been collected by riffle splitting if

dry, or by trowel if wet

* For all sample types, the nature, quality and

appropriateness of the sample preparation technique.

* Pulverised samples have been routinely checked for

size after pulverising

* Quality control procedures adopted for all

sub-sampling stages to maximise representivity of

samples. * Pulp samples were re- pulverised after storage to

re-homogenise samples prior to analysis.

* Measures taken to ensure that the sampling is

representative of the in situ material collected, 2021-onward

including for instance results for field * The use of an aluminum scoop or PVC spear to collect

duplicate/second-half sampling. the required 2-4 kg of sub-sample from each AC sample

length controlled the sample volume submitted to the

laboratory.

* Whether sample sizes are appropriate to the grain

size of the material being sampled.

* Additional sub-sampling was performed through the

preparation and processing of samples according to

the lab internal protocols.

* Duplicate AC samples were collected from the green

bags using an aluminium scoop or PVC spear at a 1 in

25 sample frequency.

* Sample sizes were appropriate for the material being

sampled.

* Assessment of duplicate results indicated this

sub-sample method provided good repeatability for

rare earth elements.

* RC drill samples were sub-sampled using a cyclone rig

mounted splitter with recoveries monitored using a

field spring scale.

* Manual re-splitting of RC samples through a riffle

splitter was undertaken where sample sizes exceeded 4

kg.

* RC field duplicate samples were taken nominally every

1 in 25 samples. These samples showed good

repeatability for REE.

============================================================ =======================================================================

Quality of

assay data * The nature, quality and appropriateness of the * Samples were submitted to Bureau Veritas Laboratories,

and assaying and laboratory procedures used and whether Adelaide for preparation and analysis.

laboratory the technique is considered partial or total.

tests

* Multi element geochemistry were digested by four acid

* For geophysical tools, spectrometers, handheld XRF ICP-MS and analysed for Ag, Ce, Cu, Dy, Er, Eu, Gd,

instruments, etc, the parameters used in determining Ho, La, Lu, Mg, Na, Nd, P, Pr, Sc, Sm, Tb, Th, Tm, U,

the analysis including instrument make and model, Y and Yb.

reading times, calibrations factors applied and their

derivation, etc.

* Field gold blanks and rare earth standards were

submitted at a frequency of 1 in 25 samples.

* Nature of quality control procedures adopted (eg

standards, blanks, duplicates, external laboratory

checks) and whether acceptable levels of accuracy (ie * Field duplicate samples were submitted at a frequency

lack of bias) and precision have been established. of 1 in 25 samples

* Reported assays are to acceptable levels of accuracy

and precision.

* Internal laboratory blanks, standards and repeats for

rare earths indicated acceptable assay accuracy.

Metallurgical Test Work performed by the Australian Nuclear Science

and Technology Organisation

(ANSTO). Samples were 40g sourced from retained 1m composite pulp

samples.

* Standard desorption conditions:

* 0.5M (NH4)2SO4 as lixiviant

* pH 4

* 30 minutes & 6 hours

* Ambient temperature of 22degC; and

* 4 wt% solids density

* Prior to commencing the test work, a bulk 0.5 M

(NH4)2SO4 solution was prepared as the synthetic

lixiviant and the pH adjusted to 4 using H2SO4.

* Each of the leach tests was conducted on 80 g of dry,

pulverised sample and 1920 g of the lixiviant in a 2

L titanium/ stainless steel baffled leach vessel

equipped with an overhead stirrer.

* Addition of solid to the lixiviant at the test pH

will start the test. 1 M H2SO4 was utilised to

maintain the test pH for the duration of the test, if

necessary. The acid addition was measured.

-- Acidic water as lixiviant (using H2SO4)

-- pH3

-- Duration: 6 hours

-- Ambient temperature of 22degC

-- 4 wt% density

* At the completion of each test, the final pH was

measured, the slurry was vacuum filtered to separate

the primary filtrate.

* 30 minute and 2 hour hour liquor sample was taken

* The primary filtrate was analysed as follows: --

ICP-MS for Ce, Dy, Er, Eu, Gd, Ho, La, Lu, Mn, Nd, Pb,

Pr, Sc, Sm, Tb, Th, Tm, U, Y, Yb (ALS, Brisbane); --

ICP-OES for Al, Ca, Fe, K, Mg, Mn, Na, Si (in-house,

ANSTO);

* The water wash was stored but not analysed.

============================================================ =======================================================================

Verification

of sampling * The verification of significant intersections by * Sampling data was recorded in field books, checked

and assaying either independent or alternative company personnel. upon digitising and transferred to database.

* The use of twinned holes. * Geological logging was undertaken digitally via the

MX Deposit logging interface and synchronised to the

database at least daily during the drill programme.

* Documentation of primary data, data entry procedures,

data verification, data storage (physical and

electronic) protocols. * Compositing of assays was undertaken and reviewed by

Cobra Resources staff.

* Discuss any adjustment to assay data.

* Original copies of laboratory assay data are retained

digitally on the Cobra Resources server for future

reference.

* Samples have been spatially verified through the use

of Datamine and Leapfrog geological software for pre

2021 and post 2021 samples and assays.

* Twinned drillholes from pre 2021 and post 2021 drill

programmes showed acceptable spatial and grade

repeatability.

* Physical copies of field sampling books are retained

by Cobra Resources for future reference.

* Significant intercepts have been prepared by Mr

Rupert Verco and reviewed by Mr Robert Blythman.

============================================================ =======================================================================

Location of Pre 2021

data points * Accuracy and quality of surveys used to locate drill * Collar locations were pegged using DGPS to an

holes (collar and down-hole surveys), trenches, mine accuracy of +/-0.5 m.

workings and other locations used in Mineral Resource

estimation.

* Downhole surveys have been completed for deeper RC

and diamond drillholes

* Specification of the grid system used.

* Collars have been picked up in a variety of

* Quality and adequacy of topographic control. coordinate systems but have all been converted to MGA

94 Zone 53. Collars have been spatially verified in

the field.

* Collar elevations were historically projected to a

geophysical survey DTM. This survey has been adjusted

to AHD using a Leica CS20 GNSS base and rover survey

with a 0.05 cm accuracy. Collar points have been

re-projected to the AHD adjusted topographical

surface.

2021-onward

* Collar locations were initially surveyed using a

mobile phone utilising the Avenza Map app. Collar

points recorded with a GPS horizontal accuracy within

5 m.

* RC Collar locations were picked up using a Leica CS20

base and Rover with an instrument precision of 0.05

cm accuracy.

* Locations are recorded in geodetic datum GDA 94 zone

53.

* No downhole surveying was undertaken on AC holes. All

holes were set up vertically and are assumed

vertical.

* RC holes have been down hole surveyed using a Reflex

TN-14 true north seeking downhole survey tool or

Reflex multishot

* Downhole surveys were assessed for quality prior to

export of data. Poor quality surveys were downgraded

in the database to be excluded from export.

* All surveys are corrected to MGA 94 Zone 53 within

the MX Deposit database.

* The quality and accuracy of the topographic control

is considered sufficient for the Mineral Resource

estimation and classification applied.

============================================================ =======================================================================

Data spacing

and * Data spacing for reporting of Exploration Results. * Drillhole spacing was designed on transects 50-80 m

distribution apart. Drillholes generally 50-60 m apart on these

transects but up to 70 m apart.

* Whether the data spacing and distribution is

sufficient to establish the degree of geological and

grade continuity appropriate for the Mineral Resource * Additional scouting holes were drilled

and Ore Reserve estimation procedure(s) and opportunistically on existing tracks at spacings

classifications applied. 25-150 m from previous drillholes.

* Whether sample compositing has been applied. * Regional scouting holes are drilled at variable

spacings designed to test structural concepts

* Data spacing is considered adequate for a saprolite

hosted rare earth Mineral Resource estimation.

* No sample compositing has been applied

* Drillhole spacing does not introduce any sample bias.

* The data spacing and distribution is sufficient to

establish the degree of geological and grade

continuity appropriate for interpretation of the REE

mineralised horizon and the classification applied.

============================================================ =======================================================================

Orientation

of data in * Whether the orientation of sampling achieves unbiased * RC drillholes have been drilled between -60 and -75

relation to sampling of possible structures and the extent to degrees at orientations interpreted to appropriately

geological which this is known, considering the deposit type. intersect gold mineralisation

structure

* If the relationship between the drilling orientation * Gold results are not presented as true width but are

and the orientation of key mineralised structures is not considered to present any down-dip bias.

considered to have introduced a sampling bias, this

should be assessed and reported if material.

============================================================ =======================================================================

Sample Pre 2021

security * The measures taken to ensure sample security. * Company staff collected or supervised the collection

of all laboratory samples. Samples were transported

by a local freight contractor

* No suspicion of historic samples being tampered with

at any stage.

* Pulp samples were collected from Challenger

Geological Services and submitted to Intertek

Genalysis by Cobra Resources' employees.

2021-onward

* Transport of samples to Adelaide was undertaken by a

competent independent contractor. Samples were

packaged in zip tied polyweave bags in bundles of 5

samples at the drill rig and transported in larger

bulka bags by batch while being transported.

* There is no suspicion of tampering of samples.

============================================================ =======================================================================

Audits or

reviews * The results of any audits or reviews of sampling * No laboratory audit or review has been undertaken.

techniques and data.

* Genalysis Intertek and BV Laboratories Adelaide are

NATA (National Association of Testing Authorities)

accredited laboratory, recognition of their

analytical competence.

============================================================ =======================================================================

Appendix 2: Section 2 Reporting of Exploration Results

Criteria JORC Code explanation Commentary

Mineral

tenement and * Type, reference name/number, location and ownership * RC drilling occurred on EL 6131, currently owned 100%

land tenure including agreements or material issues with third by Peninsula Resources limited, a wholly owned

status parties such as joint ventures, partnerships, subsidiary of Andromeda Metals Limited.

overriding royalties, native title interests,

historical sites, wilderness or national park and

environmental settings. * Alcrest Royalties Australia Pty Ltd retains a 1.5%

NSR royalty over future mineral production from

licenses EL6001, EL5953, EL6131, EL6317 and EL6489.

* The security of the tenure held at the time of

reporting along with any known impediments to

obtaining a licence to operate in the area. * Baggy Green, Clarke, Laker and the IOCG targets are

located within Pinkawillinnie Conservation Park.

Native Title Agreement has been negotiated with the

NT Claimant and has been registered with the SA

Government.

* Aboriginal heritage surveys have been completed over

the Baggy Green Prospect area, with no sites located

in the immediate vicinity.

* A Native Title Agreement is in place with the

relevant Native Title party.

=============================================================== =================================================================

Exploration

done by other * Acknowledgment and appraisal of exploration by other * On-ground exploration completed prior to Andromeda

parties parties. Metals' work was limited to 400 m spaced soil

geochemistry completed by Newcrest Mining Limited

over the Barns prospect.

* Other than the flying of regional airborne geophysics

and coarse spaced ground gravity, there has been no

recorded exploration in the vicinity of the Baggy

Green deposit prior to Andromeda Metals' work.

=============================================================== =================================================================

Geology

* Deposit type, geological setting and style of * The gold and REE deposits are considered to be

mineralisation. related to the structurally controlled basement

weathering of epidote- pyrite alteration related to

the 1590 Ma Hiltaba/GRV tectonothermal event.

* Mineralisation has a spatial association with mafic

intrusions/granodiorite alteration and is associated

with metasomatic alteration of host rocks. Epidote

alteration associated with gold mineralisation is REE

enriched and believed to be the primary source.

* Rare earth minerals occur within the saprolite

horizon. XRD analysis by the CSIRO identifies kaolin

and montmorillonite as the primary clay phases.

* SEM analysis identified REE bearing mineral phases in

hard rock:

* Zircon, titanite, apatite, andradite and epidote.

* SEM analyses identifies the following secondary

mineral phases in saprock:

* Monazite, bastanite, allanite and rutile.

* Elevated phosphates at the base of saprock do not

correlate to rare earth grade peaks.

* Upper saprolite zones do not contain identifiable REE

mineral phases, supporting that the REEs are adsorbed

to clay particles.

* Acidity testing by Cobra Resources supports that

acidity/alkalinity chemistry may act as a catalyst

for Ionic and Colloidal adsorption.

* REE mineral phase change with varying saprolite

acidity and REE abundances support that a component

of REE bursary is adsorbed to clays.

* Palaeo drainage has been interpreted from historic

drilling and re-interpretation of EM data that has

generated a top of basement model.

* The conditions within the interpreted palaeo system

are considered supportive of ionic REE

mineralisation.

=============================================================== =================================================================

Drillhole

Information * A summary of all information material to the * Exploration results are not being reported as part of

understanding of the exploration results including a the Mineral Resource area.

tabulation of the following information for all

Material drill holes:

o easting and northing of the drill hole collar

o elevation or RL (Reduced Level - elevation above sea

level in metres) of the drill hole

collar

o dip and azimuth of the hole

o down hole length and interception depth

o hole length.

* If the exclusion of this information is justified on

the basis that the information is not Material and

this exclusion does not detract from the

understanding of the report, the Competent Person

should clearly explain why this is the case.

=============================================================== =================================================================

Data

aggregation * In reporting Exploration Results, weighting averaging * Reported summary intercepts are weighted averages

methods techniques, maximum and/or minimum grade truncations based on length.

(eg cutting of high grades) and cut-off grades are

usually Material and should be stated.

* No maximum/ minimum grade cuts have been applied.

* Where aggregate intercepts incorporate short lengths

of high grade results and longer lengths of low grade * No metal equivalent values have been calculated.

results, the procedure used for such aggregation

should be stated and some typical examples of such

aggregations should be shown in detail. * Gold results are reported to a 0.3 g/t cut-off with a

maximum of 2m internal dilution with a minimum grade

of 0.1 g/t Au.

* The assumptions used for any reporting of metal

equivalent values should be clearly stated.

* Rare earth element analyses were originally reported

in elemental form and have been converted to relevant

oxide concentrations in line with industry standards.

Conversion factors tabulated below:

Element Oxide Factor

Cerium CeO(2) 1.2284

Dy(2)

Dysprosium O(3) 1.1477

Er(2)

Erbium O(3) 1.1435

Eu(2)

Europium O(3) 1.1579

Gd(2)

Gadolinium O(3) 1.1526

Ho(2)

Holmium O(3) 1.1455

La(2)

Lanthanum O(3) 1.1728

Lu(2)

Lutetium O(3) 1.1371

Nd(2)

Neodymium O(3) 1.1664

Pr(6)

Praseodymium O(11) 1.2082

Sc(2)

Scandium O(3) 1.5338

Sm(2)

Samarium O(3) 1.1596

Tb(4)

Terbium O(7) 1.1762

Tm(2)

Thulium O(3) 1.1421

Y(2)

Yttrium O(3) 1.2699

Yb(2)

Ytterbium O(3) 1.1387

========

* The reporting of REE oxides is done so in accordance

with industry standards with the following

calculations applied:

* TREO = La(2) O(3) + CeO(2) + Pr(6) O(11) + Nd(2) O(3)

+ Sm(2) O(3) + Eu(2) O(3) + Gd(2) O(3) + Tb(4) O(7) +

Dy(2) O(3) + Ho(2) O(3) + Er(2) O(3) + Tm(2) O(3) +

Yb(2) O(3) + Lu(2) O(3) + Y(2) O(3)

* CREO = Nd(2) O(3) + Eu(2) O(3) + Tb(4) O(7) + Dy(2)

O(3) + Y(2) O(3)

* LREO = La(2) O(3) + CeO(2) + Pr(6) O(11) + Nd(2) O(3)

* HREO = Sm(2) O(3) + Eu(2) O(3) + Gd(2) O(3) + Tb(4)

O(7) + Dy(2) O(3) + Ho(2) O(3) + Er(2) O(3) + Tm(2)

O(3) + Yb(2) O(3) + Lu(2) O(3) + Y(2) O(3)

* NdPr = Nd(2) O(3) + Pr(6) O(11)

* TREO-Ce = TREO - CeO(2)

* % Nd = Nd(2) O(3) / TREO

* %Pr = Pr(6) O(11) /TREO

* %Dy = Dy(2) O(3) /TREO

* %HREO = HREO/TREO

* %LREO = LREO/TREO

=============================================================== =================================================================

Relationship

between * These relationships are particularly important in the * Preliminary results support unbiased testing of

mineralisation reporting of Exploration Results. mineralised structures.

widths and

intercept

lengths * If the geometry of the mineralisation with respect to * Previous holes have been drilled in several

the drill hole angle is known, its nature should be orientations due to the unknown nature of

reported. mineralisation.

* If it is not known and only the down hole lengths are * Most intercepts are vertical and reflect true width

reported, there should be a clear statement to this intercepts.

effect (eg 'down hole length, true width not known').

* Exploration results are not being reported for the

Mineral Resource area.

=============================================================== =================================================================

Diagrams

* Appropriate maps and sections (with scales) and * Relevant diagrams have been included in the

tabulations of intercepts should be included for any announcement.

significant discovery being reported These should

include, but not be limited to a plan view of drill

hole collar locations and appropriate sectional * Exploration results are not being reported for the

views. Mineral Resources area.

=============================================================== =================================================================

Balanced

reporting * Where comprehensive reporting of all Exploration * Not applicable - Mineral Resource and Exploration

Results is not practicable, representative reporting Target are defined.

of both low and high grades and/or widths should be

practiced to avoid mISReading reporting of

Exploration Results. * Exploration results are not being reported for the

Mineral Resource area.

=============================================================== =================================================================

Other

substantive * Other exploration data, if meaningful and material, * Refer to previous announcements listed in RNS for

exploration should be reported including (but not limited to): reporting of REE results , metallurgical testing and

data geological observations; geophysical survey results; detailed gold intersections.

geochemical survey results; bulk samples - size and

method of treatment; metallurgical test results; bulk

density, groundwater, geotechnical and rock

characteristics; potential deleterious or

contaminating substances.

=============================================================== =================================================================

Further work

* The nature and scale of planned further work (eg * Infill and extensional drilling aimed at growing the

tests for lateral extensions or depth extensions or Mineral Resource and converting Inferred Resources to

large-scale step-out drilling). Indicated Resources is planned.

* Diagrams clearly highlighting the areas of possible

extensions, including the main geological

interpretations and future drilling areas, provided

this information is not commercially sensitive.

=============================================================== =================================================================

This information is provided by RNS, the news service of the

London Stock Exchange. RNS is approved by the Financial Conduct

Authority to act as a Primary Information Provider in the United

Kingdom. Terms and conditions relating to the use and distribution

of this information may apply. For further information, please

contact rns@lseg.com or visit www.rns.com.

RNS may use your IP address to confirm compliance with the terms

and conditions, to analyse how you engage with the information

contained in this communication, and to share such analysis on an

anonymised basis with others as part of our commercial services.

For further information about how RNS and the London Stock Exchange

use the personal data you provide us, please see our Privacy

Policy.

END

UPDEASNPEFSDEFA

(END) Dow Jones Newswires

September 11, 2023 02:00 ET (06:00 GMT)

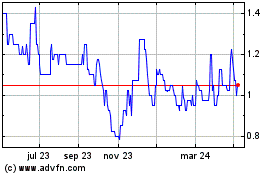

Cobra Resources (LSE:COBR)

Gráfica de Acción Histórica

De Abr 2024 a May 2024

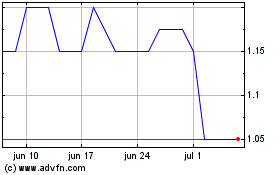

Cobra Resources (LSE:COBR)

Gráfica de Acción Histórica

De May 2023 a May 2024