UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, DC 20549

FORM SD

Specialized Disclosure Report

LANTRONIX, INC.

(Exact name of registrant as specified in its charter)

| DELAWARE |

|

1-16027 |

|

33-0362767 |

(State or other jurisdiction

of incorporation) |

|

(Commission File Number) |

|

(IRS Employer

Identification No.) |

48 Discovery, Suite 250

Irvine, California 92618

(Address of principal executive offices, including

zip code)

Jeremy Whitaker

(949) 453-3990

(Name and telephone number, including area code, of

the person to contact in connection with this report.)

Check the appropriate box to indicate the rule pursuant

to which this form is being filed, and provide the period to which the information in this form applies:

| |

☒ |

Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2023. |

Section 1 – Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

A copy of Lantronix, Inc.’s Conflict Minerals

Report for the calendar year ended December 31, 2023 is filed as Exhibit 1.01 hereto and is publicly available at the Company’s

website at www.lantronix.com. The contents of the Company’s website are not incorporated by reference into this Form SD or its Exhibits.

Item 1.02 Exhibits

A copy of the Company’s Conflict Minerals Report

required by Item 1.01 of this Form SD is filed as Exhibit 1.01 hereto.

Section 2 – Exhibits

Item 2.01 Exhibits

The following exhibit is filed as part of this report:

SIGNATURES

Pursuant to the requirements

of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

| |

Date: May 24, 2024 |

LANTRONIX, INC. |

| |

|

|

| |

By: |

/s/ Jeremy Whitaker |

|

| |

|

Jeremy Whitaker

Chief Financial Officer |

EXHIBIT INDEX

Exhibit 1.01

Lantronix, Inc.

Conflict Minerals Report

For the Year Ended December 31, 2023

This Conflict Minerals Report (the “Report”)

of Lantronix, Inc. (the “Company,” “Lantronix,” “we,” “our,” or “us”) has

been prepared pursuant to Rule 13p-1 and Form SD (the “Rule”) promulgated under the Securities Exchange Act of 1934 for the

reporting period January 1, 2023 to December 31, 2023.

The Rule requires disclosure of certain information

when a company manufactures or contracts to manufacture products for which the minerals specified in the Rule are necessary to the functionality

or production of those products. The specified minerals, which we collectively refer to in this Report as the “Conflict Minerals,”

are gold, columbite-tantalite (coltan), cassiterite and wolframite, including their derivatives, which are limited to tantalum, tin and

tungsten. The “Covered Countries” for the purposes of the Rule and this Report are the Democratic Republic of the Congo and

certain adjoining countries.

We have adopted a Conflict Minerals Policy which is

available on our website at www.lantronix.com.

Lantronix is a global Industrial and Enterprise internet

of things (“IoT”) provider of solutions that target diversified verticals ranging from Smart Cities, Utilities and Healthcare

to Enterprise, Intelligent Transportation, and Industrial Automation. Building on a long history of connectivity and video processing

competence, target applications include Video Surveillance, Traffic management, Infotainment systems, Robotics, Edge Computing and Remote

Environment Management (“REM”).

We organize our products and solutions into three product

lines: Embedded IoT Solutions, IoT System Solutions, and Software & Services.

Embedded IoT Modules

This portfolio of embedded products provides a variety

of options including Compute System-on-Module (SOM) or System-in-Package (SIP) solutions supplemented with wired and wireless network

connectivity products. As the level of silicon integration continues to grow, the compute modules also provide the ability to collect

digital information (Video, Audio or Sensors) and analyze/comprehend the data streams based on specific AI/ML algorithms. The new implementations

of SIP devices can process multiple media streams with CV (Computer Vision) technology and the modules can be controlled remotely via

ConsoleFlow™, Lantronix’s Cloud SaaS platform. Our IoT compute products typically are embedded into a customer new product

design, enabling advanced application functionality at the edge. These products include application processing that delivers compute to

meet customer needs for data transformation, computer vision, machine learning, augmented / virtual reality, audio / video aggregation

and distribution, and custom applications at the edge. Many of the products are offered with software tools intended to further accelerate

our customers’ time-to-market and increase their value add. Most of our IoT embedded products are pre-certified in a number of countries

thereby significantly reducing our OEM customers’ regulatory certification costs and accelerating their time to market.

The following product families are included in our

Embedded IoT Solutions product line: XPort®, XPort® Pro, WiPort®, System on Module (“SoM”), Single Board Computer

(“SBC”), Development Kits, MicroM110, xPico®, xPico® Wi-Fi, NICS, Optical SFPs, PremierWave® EN, and PremierWave®

XC.

IoT System Solutions

The IoT Systems Solutions portfolio consists of fully

functional standalone systems that provider routing, switching or gateway functionalities as well as Telematics and media conversion.

These products include wired and wireless connections that enhance the value and utility of modern electronic systems and equipment by

providing secure network connectivity, power for IoT end devices through Power over Ethernet (PoE), application hosting, protocol conversion,

media conversion, secure access for distributed IoT deployments and many other functions. Most of our IoT System products are pre-certified

in a number of countries thereby significantly reducing our original equipment manufacturer (“OEM”) customers’ regulatory

certification costs and accelerating their time to market.

Our PoE products support remote devices such as cameras

and wireless access points by passing electrical power along with data on Ethernet cabling, eliminating the need for traditional AC/DC

electrical power in hard-to-reach locations. As more cities move to implement smart city technology, a major component will be solutions

designed to protect and provide services to citizens, such as intelligent transportation and surveillance networks. Our switches deliver

the necessary connectivity, bandwidth and power to enable these solutions. Many of our products incorporate features to perform advanced

levels of fault management and diagnostics to troubleshoot networks and proactively fix problems. Our media converters and other customer

premise equipment (“CPE”) assist customers in resolving challenges in the areas of bandwidth constraints, security risks,

and distance limitations as networks extend from local area to wide area networks and adapt to ever increasing end-user demands.

Our smart tracking devices are designed to deliver

robust data logging and positional tracking functionality and reliability for supply chain and logistics solutions. Our telematics devices

are designed to be flexible in the field and offer a variety of connectivity options to suit the customers’ needs across 3G, 4G,

and LTE cellular networks. These power efficient products are designed to support communications across interfaces and industrial protocols

for vehicle, fleet, and asset tracking and management. Many of the products are offered with software tools intended to further accelerate

our customers’ time-to-market and increase their value add. Most of our IoT Telematics products are pre-certified in a number of

countries thereby significantly reducing our OEM customers’ regulatory certification costs and accelerating their time to market.

As Edge Computing deployment accelerates, REM allows

for full comprehension and control of a remote IT infrastructure, across a range of sensors (temperature, humidity, light, acceleration,

open / close, etc.) providing status and alerting, automation, and remote control of devices and end stations. REM designs may be part

of an out of band (“OOB”) or in band network design. OOB is a technique that uses a dedicated management network to access

critical infrastructure components to ensure production independent management connectivity. REM allows organizations to effectively monitor,

manage, and control their enterprise IT equipment and facilities (environments), either in or out of band, optimizing their IT support

resources.

Our REM product line includes out-of-band management,

console management, power management, and IP connected keyboard-video-mouse (commonly referred to as “IPKVM”) products that

provide remote access to IT and networking infrastructure deployed in test labs, data centers, branch offices, remote sites, and server

rooms.

The following product families are included in IoT

System Solutions product line: EDS, EDS-MD, xPress™, xDirect®, E21x, E22x, G52x, X30x, Bolero4x, FOX3-4G, FOX4, SGX™,

SLB™, SLC™8000, Spider™, UDS, EMG™. S40 and Power over Ethernet Switches.

In addition, we offer non-PoE Network Switches and Media Converters.

Software and Engineering Services

Our SaaS platform provides single pane of glass management

for REM and IoT deployments. Our platform enables customers to easily deploy, monitor, manage, and automate across their global deployments,

all from a single platform login, virtually connected as though directly on each device. Our platform eliminates the need to have 24/7

personnel on site, and makes it easy to see and drill into an issue quickly, even in large scale deployments.

OEMs and SIs can leverage our platform multitenancy

functionality for supporting a wide customer base while ensuring customer separation. Over the Air (“OTA”) updates make it

easy to ensure the latest security patches, firmware, and configurations are deployed and functional.

We leverage our engineering expertise and product development

best practices to deliver high quality, innovative products, cost-effectively and on time.

Our engineering services flexible business model allows

for choosing turnkey product development or team augmentation for accelerating complex areas of product development such as; camera development

and tuning, voice control, machine learning, artificial intelligence, computer vision, augmented / virtual reality, mechanical and radio-frequency

design, thermal and power optimization, or in any specific area a customer needs assistance.

In addition to our production-ready edge computing

solutions, we offer experienced multidisciplinary engineering services across complete aspects of IoT product development, including hardware

engineering, software engineering, mechanical engineering, rapid prototyping, and quality assurance. We also offer services for mechanical,

hardware, and software engineering for camera, audio, and artificial intelligence / machine learning development.

The following product families are included in our

Software & Services product line: Engineering Services, ConsoleFlow™, Level Services and J-Integra.

Our manufacturing operations are primarily conducted

through third-party contract manufacturers located in Asia. Our contract manufacturers, in turn, source the raw materials, components

and integrated circuits used to manufacture our products from numerous sub-tier suppliers. We currently have four active contract manufacturers

in Asia who are the direct suppliers of substantially all of our products. In addition, we have identified approximately 167 active indirect

suppliers who supply components used in our products to our contract manufacturers.

Our supply chain is complex. There are multiple tiers

in the supply chain between Lantronix and the mines and smelters that produce Conflict Minerals. In this regard, we do not purchase Conflict

Minerals directly from mines, smelters or refiners. As a result, we must rely upon our direct and indirect suppliers to provide information

on the origin of the Conflict Minerals contained in our products, including sources of Conflict Minerals that are supplied to them from

sub-tier suppliers.

| |

4. |

Conflict Minerals Compliance Process |

We have implemented a reasonable country of origin

inquiry process and designed due diligence measures to conform in all material respects with the framework in The Organization for Economic

Co-operation and Development (the “OECD”) Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected

and High-Risk Areas (the “OECD Guidelines”).

Reasonable Country of Origin Inquiry. Our reasonable

inquiry into the source countries of Conflict Minerals found in our products (“Reasonable Country of Origin Inquiry”) was

designed to provide a reasonable basis for us to determine whether we source Conflict Minerals from the Covered Countries. The methods

we used to try to determine the origin of Conflict Minerals in our products included (1) soliciting survey responses from relevant direct

and indirect suppliers of components of our products, using the standard Conflict Minerals Reporting Template (the “CMRT”)

designed by the Responsible Minerals Initiative (the “RMI”), which is an initiative of the Electronic Industry Citizenship

Coalition and the Global e-Sustainability Initiative; (2) reviewing responses that we received from our direct and indirect suppliers

and following up on inconsistent, incomplete, and inaccurate responses; and (3) sending reminders to suppliers who did not respond to

our requests for information.

Management Systems. We have communicated our

Conflict Minerals Policy, which includes a reference to the OECD Guidelines, to our suppliers and customers. This policy is publicly available

on our website at www.lantronix.com. We also have an internal team tasked with supporting supply chain due diligence. All responses from

suppliers to our inquiries regarding Conflict Minerals are recorded and stored. There is also a program in place to improve the quality

and number of supplier responses. Conflict Minerals compliance is included in new commercial supply contracts and written agreements.

Our existing internal whistleblower policy provides a company-level grievance mechanism which covers reporting securities law compliance

issues including those regarding Conflict Minerals sourcing.

Identifying and Assessing Risk in Our Supply Chain.

Because of the nature of our supply chain, it is difficult for us to identify actors upstream from our suppliers. Accordingly, while we

participate in industry-wide initiatives, we ultimately must rely on our suppliers to provide information on actors upstream from them.

In most cases, our suppliers are themselves several steps removed from the smelters and refiners of the Conflict Minerals contained in

the component parts incorporated into our products. We have a process to review supplier responses for accuracy and completeness, follow

up with delinquent suppliers, and update supplier information.

Strategy for Responding to Risks. A risk management

process has been adopted to evaluate our suppliers periodically with respect to a number of criteria, including compliance with our Conflict

Minerals Policy. Updates to this risk management process are provided regularly to senior management. If Lantronix discovers the use of

Conflict Minerals used in any material, parts or components we procure are not “DRC conflict free,” we will attempt to work

with the supplier concerned to correct the situation and/or take other appropriate actions to transition to “DRC conflict free”

alternatives.

Independent Third Party Audit of Supply Chain Due

Diligence. We do not have direct relationships with Conflict Minerals smelters or refiners and do not perform or direct audits of

these entities within our supply chain. We intend to rely on the risk management and due diligence processes of the RMI Responsible Minerals

Assurance Program (“RMAP”), including the program’s independent third-party audit process.

Report on Supply Chain Due Diligence. In accordance

with the OECD Guidelines and the Rule, this Report is available on our website at www.lantronix.com.

| |

5. |

Efforts to Determine Origins of Conflict Minerals in our Products |

Based on the breadth and complexity of our products

and supply chain, we believe that seeking information about Conflict Minerals smelters and refiners in our supply chain from our direct

and indirect suppliers represents the most reasonable effort we can make to determine the mines or locations of origin of the Conflict

Minerals in our products.

Supplier Surveys. We conducted a survey of our

direct and indirect suppliers using the CMRT. The CMRT was developed to facilitate disclosure and communication of information regarding

smelters that provide material to a company’s supply chain.

Survey Responses and Follow-up Engagement. During

our Reasonable Country of Origin Inquiry and related due diligence efforts, we sent the CMRT to approximately 167 direct and indirect

suppliers and received responses from 100% of the suppliers surveyed. We also reviewed the responses to determine which required further

engagement with our suppliers. Based on our communications with suppliers we gathered information regarding a portion of the smelters

or refineries of Conflict Minerals in our supply chain.

The large majority of the responses to the CMRT that

we received for 2023 provided data at the supplier company-wide level, rather than at a level directly relating to specific part numbers

that the supplier supplies to us, or were otherwise unable to specify the smelters or refiners used for components supplied to us. As

a result, we do not have sufficient information from our suppliers or other sources to determine the country of origin of the Conflict

Minerals used in our products or identify the facilities used to process those Conflict Minerals.

Using our due diligence processes, we hope to further

improve transparency into our supply chain. We continue to engage with our suppliers with the goal of increasing supplier response rates

and improving the content of the supplier survey responses we receive. We also continue to work with our suppliers to encourage them to

source from certified RMAP smelters, when sourcing material from the Covered Countries.

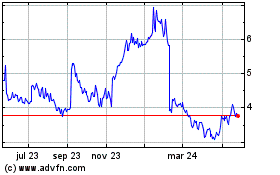

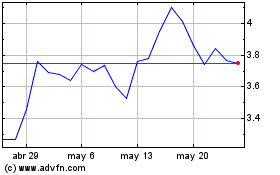

Lantronix (NASDAQ:LTRX)

Gráfica de Acción Histórica

De May 2024 a Jun 2024

Lantronix (NASDAQ:LTRX)

Gráfica de Acción Histórica

De Jun 2023 a Jun 2024