TIDMTHR

RNS Number : 3505C

Thor Mining PLC

22 February 2022

22 February 2022

Thor Mining PLC

Project Advancement

Alford East Copper-Gold ISR Project, South Australia

The directors of Thor Mining Plc ("Thor") (AIM, ASX: THR, OTCQB:

THORF) are pleased to provide an update on the Alford East

Copper-Gold Project, SA, Australia.

Project highlights:

-- Significant intercepts including:

21AED001 32.9m @ 0.4% Cu and 0.31g/t Au from 81.5m (AIM:THR Announcement 31.8.2021),

21AED002 59.9m @ 0.3% Cu from 21.9m (AIM:THR Announcement 31.8.2021),

21AED003 32.4m @ 0.2% Cu and NSR Au from 15m,

21AED004 55.9m @ 0.53% Cu from 7m, including

11.7m @ 1.0%Cu from 17.3m including

5.7m @ 1.23% and 0.16g/t Au from 17.3

21AED005 72.7m @ 1.0% Cu and 0.19g/t Au from 6.3m, including

18.2m @ 2.0% Cu and 0.34g/t Au from 15.8m ( AIM:THR Announcement

31.8.2021),

-- A robust 3D geological model generated from recent drilling

data highlights key structural and lithological controls on

mineralisation and potential high-grade target zones.

-- Initial hydrometallurgy trialling of an environmentally

friendly glycine lixiviant shows positive gold and copper

recovery.

-- Phase two diamond drilling program is being designed, including continuing hydrogeology and hydrometallurgical studies.

Nicole Galloway Warland, Managing Director of Thor Mining,

commented:

"The success of our first phase of drilling, with significant

uplift in copper and gold grade, adjacent to the Netherleigh Fault,

is very exciting and suggests the potential for extended zones of

higher-grade copper and gold along strike and at depth.

Demonstrating Thor's greater understanding of the geological and

structural constraints through the new geological modelling is

critical to the overall project's development, especially as we

plan our second phase of drilling and progress our

hydrometallurgical studies.

These favourable initial hydrometallurgical results for the

metal recovery for both copper and gold using a socially and

environmentally friendly solution 'glycine' rather than

conventional acid in-situ recovery (ISR) is significant, as Thor

strives towards the in-situ assessment of the Alford East

Project."

Figure 1: Tenement & Prospect Location Plan and Mineral

Resource Domains may be viewed on the following links:

http://www.thormining.com/sites/thormining/media/maps/21-001-4-ae-mre-%E2%80%93-location.jpg

https://www.thormining.com/sites/thormining/media/Maps/mre_ae_5-drilling.jpg

Alford East Project

The Alford East Copper-Gold Project is located on EL6529, where

Thor is earning up to 80% interest from unlisted Australian

explorer Spencer Metals Pty Ltd, covering portions of EL6255 and

EL6529 (Figure 1) (ASX: THR Announcement 23 November 2020).

The Alford East Project covers the northern extension of the

Alford Copper Belt, located on the Yorke Peninsula, SA. The Alford

Copper Belt is a semi coherent zone of copper-gold oxide

mineralisation, within a structurally controlled, north-south

corridor consisting of deeply kaolinised and oxidised troughs

within metamorphic units on the edge of the Tickera Granite (Figure

1), Gawler Craton, SA.

Utilising historic drill hole information, Thor completed an

inferred Mineral Resource Estimate (MRE) (AIM: THR Announcement 26

January 2021):

-- 125.6Mt @ 0.14% Cu containing 177,000t of contained

copper

-- 71,500oz of contained gold

www.thormining.com/sites/thormining/media/pdf/asx-announcements/20210127-maiden-copper.gold-estimate-alford-east-sa.pdf

Based on the nature on the oxide mineralisation, the deposit is

considered amenable to In-Situ Recovery (ISR) techniques. For

further information on ISR please refer to Thor's website via this

link for an informative video:

www.youtube.com/watch?v=eG_1ZGD0WIw

Alford East Diamond Drilling Program Update

The first phase of drilling comprised nine diamond drillholes

totalling 878m, with assays now received for all drillholes. This

initial program for Thor focused only on the northern portion of

the Alford East copper-gold deposit around the AE-5 mineralised

domains (Figure 1 and 2), with drilling targeting areas open at

depth and along strike.

Drillhole assay results are reported in Table B and C

(Appendices).

Figure 2: Alford East Project AE-5 domain showing drillhole

location plan may be viewed via the following link:

https://www.thormining.com/sites/thormining/media/Maps/ae-5-location-plan.jpg

For ISR purposes, drilling was limited to the deeply weathered

lithological profile, testing the extent of the oxide zone and the

depth boundary of the Top of Fresh Rock (TOFR). The copper-gold

oxide mineralisation is hosted within deeply kaolinised (clay) and

metasomatic altered units on the contact between the Olympic Domain

Wallaroo Group metasediments and the Hiltaba Suite Tickera Granite,

Gawler Craton (Figure 1). Copper oxide mineralogy is dominated by

malachite and chalcocite.

Drill targeting, vectoring in on the hanging wall side of the

north-south trending controlling structure, now referred to as

Netherleigh Park Fault, intercepted zones of high-grade copper and

gold grades resulted in significant grade uplift in comparison to

the MRE.

Drillholes 21AED001, 21AED003 and 21AED005 (Section A-A'

6,256,360mN) were drilled through the central portion of AE-5

(Figure 3), designed to validate the geological model and test

areas, open at depth. The high-grade copper and gold intercepts in

21AED001 opens the mineralisation up at depth, whilst 21AED005

highlights the grade uplift along the Netherleigh Park Fault.

21AED004 (Section B-B' 6,235,440mN) was drilled along strike to

the north 21AED005, a continuation of higher copper grades along

fault (Figure 2 and 4).

21AED002, 21AED006 and 21AED007 (Section C-C' 6,235,600mN) were

all drilled to the north of the AE-5 MRE domain, with assay results

extending the known copper mineralisation along strike towards AE-8

(Figure 2, 3 and 6).

Multi-element analysis of the assay results highlights two

distinct higher-grade zones of copper-gold mineralisation within a

broader mineralised envelope. The lower of the two has a distinct

IOCG geochemical signature - elevated Cu, Au, Mo, Co, Se, Bi &

REE (Figure 6 log plot). This potentially reflects sulphide

oxidation of primary mineralisation; whilst the upper zone has a

more amorphous distribution typical of a supergene mineralised

system .

Figure 3: Cross section 6,256,360mN looking NNE, showing

21AED001, 21AED003 and 21AED005 with c opper assays shown as

cylinder down hole trace may be viewed via the following link:

http://www.thormining.com/sites/thormining/media/pdf/asx-announcements/20202021/2022.02.17-section-a-6256360mn-incl-21aed001-21aed003-21aed005-final-assays.jpg

Figure 4: Cross section 6,256,4400mN looking NNE, showing

21AED004, with copper assays shown as cylinder downhole trace may

be viewed via the following link:

http://www.thormining.com/sites/thormining/media/pdf/asx-announcements/20202021/2022.02.17-section-b-6256440mn-incl-21aed004-final-assays.jpg

Figure 5: Cross section 6,256,600mN showing 21AED002 and

21AED007 , with copper assays shown as cylinder downhole trace may

be viewed via the following link;

http://www.thormining.com/sites/thormining/media/pdf/asx-announcements/20202021/2022.02.17-section-c-6256600mn-incl-21aed002-and-21aed007-final-assays.jpg

Figure 6: Multi-element log plot for 21AED001 showing two

distinct higher grade copper zones with the lower gold rich zone

reflecting IOGC geochemical signature may be viewed via the

following link:

http://www.thormining.com/sites/thormining/media/Maps/21aed001_log-plot.jpg

New Alford East Geological Model

Based on the recent diamond drilling, a new robust 3D geological

model was generated (Figure 7) using a combination of weathering,

lithology, assay and structural data from logging, and regional

geology, structural and geophysics (magnetics and gravity)

data.

Key geological outcomes:

-- The best oxide mineralisation seems to occur where a fault

has facilitated a more deeply weathered profile.

-- Some faults appear to have had minor vertical offset on them

post-development of the weathering profile (for example, the

north-east trending Netherleigh Park Fault, central to the project

area).

-- Mineralisation shows a preference to metasediments.

-- A Sulphidic-Magnetic-Shale (SMS) stratigraphic-alteration

unit, appears as a marker unit in the regional and more local

magnetics images, as well as in the regional 3D magnetics and

gravity inversions.

-- The SMS unit was modelled using the information above,

showing an overall synformal shape with AE3 sitting in the core or

trough of overlying metasediments formed by the synform.

-- Most supergene mineralisation appears to occur in the hanging

wall of the SMS, whilst the weathered primary mineralisation (such

as in the deeper sections of AE8 and AE5) appears to be associated

with major faults, such as the central Netherleigh Park Fault.

Figure 7: 3D Geological Model - showing the major faults in

black, cover in translucent brown, weathered rock in translucent

green, fresh rock in translucent yellow, suphidic-magnetic-shale

(SMS), and the resource domains in green may be viewed via the

following link:

http://www.thormining.com/sites/thormining/media/pdf/asx-announcements/20202021/ae_basement-geology.jpg

Hydrometallurgy

Thor's objective is to identify an in-situ recovery pathway,

ideally for both the copper and gold mineralisation at the Alford

East Project, that is socially and environmentally friendly rather

than using conventional acid in-situ recovery (ISR).

This has led to Thor engaging Mining Processing Solutions (MPS)

trialling their alkaline Glycine Leaching Technology (GLT), branded

as their GlyCat(TM) and GlyLeach(TM) processes, that have the

capability to selectively leach base and precious metals using

glycine as the principal, eco-friendly, reagent.

A preliminary 'Discovery' metallurgical test program has been

carried out to determine the amenability of the Alford East

mineralisation to metal recovery using GLT. The test work has

involved two rounds of Diagnostic Leach Tests (DLTs), and one round

of Bottle Roll Tests (BRTs) (Figure 8) on the two samples from

21AED001 (Table D). The two zones are highlighted in Figure 6.

Ground water collected from Alford East was used in the laboratory

test work to ensure water characteristic especially pH were

tailored to Project conditions.

Table D: Samples Selected for testing - Fire and 4 Acid Digest

assay Results (ALS Laboratories)

Hole ID Sample Assay ID Cu (ppm) Au (ppm)

21AED001 AE Upper Zone THOM-01-002 1,080 0.02

---------------- -------------- ------------ ------------

21AED001 AE Lower Zone THOM-01-001 4,920 1.10

---------------- -------------- ------------ ------------

21AED001 Combined THOM-01-003 2,950 0.51

---------------- -------------- ------------ ------------

Figure 8: Overview of Test work may be viewed via the following

link:

http://www.thormining.com/sites/thormining/media/pdf/asx-announcements/20202021/initial-test-work.jpg

Initial Findings:

-- Based on copper sequential analysis (identifies leachable

copper mineralogy) - 15% of the copper from the upper zone and up

to 50% from the lower zone should be theoretically leachable with

GLT.

-- Based on the gold diagnostic leach assays, extraction from

the lower zone of up to 73.4% should be theoretically leachable

with GLT. Upper zone had negligible gold.

-- Diagnostic Leach test- designed to be initial comparison

tests to ascertain the response to a range of conditions including

a baseline cyanidation test.

-- Bottle Roll tests (6):

-- The composite sample performed very well with GLT, extracting

98.1% of the gold and over 40% of the copper.

-- Lower zone using GLT extracting 78.3% of the gold and 33.5%

of the copper, whilst the Lower zone using cyanide extracted 64.1%

Au and 48.2% of the copper

-- The alkaline Glycine Leaching Technology (GLT) has slower

leaching dynamics, than cyanidation, so if given more time higher

extractions would be expected

Next Step

Based on the new geological model, approximately 10 diamond

drill holes have been designed to test potential high-grade zones

(Figure 9):

-- Along strike and up-dip of deeply weathered zones,

-- Targeting controlling key structures including the

Netherleigh Park Fault at depth especially where there are large

gaps in existing data,

-- Targeting intersection of SMS and Liaway offset Fault,

-- Targeting intersection of Netherleigh Park Fault and Liaway

Fault

-- Targeting subordinate splays off Netherleigh Park Fault where

there is evidence of a deep weathering trough.

In addition, hydrogeological water bores and pump testing is in

planning to determine aquifer connectivity between holes, with

initial focus in the northern area of the mineralisation.

Concurrent to drilling, hydrometallurgical work will continue to

investigate and optimise both copper and gold metal extraction

using environmentally friendly lixiviants.

Figure 9: Phase two proposed drillholes, targeting potential

higher-grade zones open at depth and along strike may be viewed via

the following link.

http://www.thormining.com/sites/thormining/media/pdf/asx-announcements/20202021/phase-2-drilling-proposal.jpg

This announcement is authorised for release to the market by the

Board of Directors.

For further information, please contact:

Thor Mining PLC

Nicole Galloway Warland, Managing Director Tel: +61 (8) 7324 1935

Ray Ridge, CFO / Company Secretary Tel: +61 (8) 7324 1935

WH Ireland Limited (Nominated Adviser Tel: +44 (0) 207 220 1666

and Joint Broker)

Jessica Cave / Darshan Patel / Megan Liddell

SI Capital Limited (Joint Broker) Tel: +44 (0) 1483 413 500

Nick Emerson

Yellow Jersey (Financial PR) thor@yellowjerseypr.com

Sarah Hollins / Henry Wilkinson Tel: +44 (0) 20 3004 9512

Elements: Cu=Copper, Au = Gold, Ag=Silver, Mo=Molybdenum,

Co=Cobalt, Se= Selenium, Bi=Bismuth, Ba=Barium and Te=Tellurium

MAR

This announcement contains inside information for the purposes

of Article 7 of the UK version of Regulation (EU) No 596/2014 which

is part of UK law by virtue of the European Union (Withdrawal) Act

2018, as amended ("MAR"). Upon the publication of this announcement

via a Regulatory Information Service, this inside information is

now considered to be in the public domain.

Competent Persons Report

The information in this report that relates to Exploration

Results and the Estimation and Reporting of the Alford East Mineral

Resource Estimation is based on information compiled by Nicole

Galloway Warland, who holds a BSc Applied geology (HONS) and who is

a Member of The Australian Institute of Geoscientists. Ms Galloway

Warland is an employee of Thor Mining PLC. She has sufficient

experience which is relevant to the style of mineralisation and

type of deposit under consideration and to the activity which she

is undertaking to qualify as a Competent Person as defined in the

2012 Edition of the 'Australasian Code for Reporting of Exploration

Results, Mineral Resources and Ore Reserves'. Nicole Galloway

Warland consents to the inclusion in the report of the matters

based on her information in the form and context in which it

appears.

Forward Looking Statements

This document may contain certain forward-looking statements.

Forward-looking statements include, but are not limited to,

statements concerning Thor Mining PLC current expectations,

estimates and projections about the industry in which Thor

operates, and beliefs and assumptions regarding Thor's future

performance. When used in this document, words such as

"anticipate", "could", "plan", "estimate", "expects", "seeks",

"intends", "may", "potential", "should", and similar expressions

are forward-looking statements. Although Thor believes that its

expectations reflected in these forward-looking statements are

reasonable, such statements are subject to known and unknown risks,

uncertainties and other factors, some of which are beyond the

control of Thor and no assurance can be given that actual results

will be consistent with these forward-looking statements

Updates on the Company's activities are regularly posted on

Thor's website www.thormining.com , which includes a facility to

register to receive these updates by email, and on the Company's

twitter page @ThorMining .

About Thor Mining PLC

Thor Mining PLC (AIM, ASX: THR; OTCQB: THORF) is a diversified

resource company quoted on the AIM Market of the London Stock

Exchange, ASX in Australia and OTCQB Market in the United

States.

The Company is advancing its diversified portfolio of precious,

base, energy and strategic metal projects across USA and Australia.

Its focus is on progressing its copper, gold, uranium and vanadium

projects, while seeking investment/JV opportunities to develop its

tungsten assets.

Thor owns 100% of the Ragged Range Project, comprising 92 km(2)

of exploration licences with highly encouraging early-stage gold

and nickel results in the Pilbara region of Western Australia, for

which initial drilling was carried out in 2021

At Alford East in South Australia, Thor is earning an 80%

interest in copper deposits considered amenable to extraction via

In Situ Recovery techniques (ISR). In January 2021, Thor announced

an Inferred Mineral Resource Estimate of 177,000 tonnes contained

copper & 71,000 oz gold(1).

Thor also holds a 30% interest in Australian copper development

company EnviroCopper Limited, which in turn holds rights to earn up

to a 75% interest in the mineral rights and claims over the

resource on the portion of the historic Kapunda copper mine and the

Alford West copper project, both situated in South Australia, and

both considered amenable to recovery by way of ISR.(2)(3)

Thor holds 100% interest in two private companies with mineral

claims in the US states of Colorado and Utah with historical

high-grade uranium and vanadium drilling and production

results.

Thor holds 100% of the advanced Molyhil tungsten project,

including measured, indicated and inferred resources , in the

Northern Territory of Australia, which was awarded Major Project

Status by the Northern Territory government in July 2020.

Adjacent to Molyhil, at Bonya, Thor holds a 40% interest in

deposits of tungsten, copper, and vanadium, including Inferred

resource estimates for the Bonya copper deposit, and the White

Violet and Samarkand tungsten deposits.

Notes

(1)

www.thormining.com/sites/thormining/media/pdf/asx-announcements/20210127-maiden-copper.gold-estimate-alford-east-sa.pdf

(2)

www.thormining.com/sites/thormining/media/pdf/asx-announcements/20172018/20180222-clarification-kapunda-copper-resource-estimate.pdf

(3)

www.thormining.com/sites/thormining/media/aim-report/20190815-initial-copper-resource-estimate---moonta-project---rns---london-stock-exchange.pdf

(4)

www.thormining.com/sites/thormining/media/pdf/asx-announcements/20210408-molyhil-mineral-resource-estimate-updated.pdf

(5)

www.thormining.com/sites/thormining/media/pdf/asx-announcements/20200129-mineral-resource-estimates---bonya-tungsten--copper.pdf

Table A: Alford East Mineral Resource Estimate as at 22 January

2021, with AR-5 extending towards AE-8 domains (previously

Netherleigh Park) the focus of the current drilling program

highlighted - Figure 2.

Domain Tonnes Cu % Au g/t Contained Cu Contained Au

( Mt) (t) (oz)

AE_1 24.6 0.12 0.021 30,000 16,000

------- ----- ------- ------------- -------------

AE_2 6.8 0.13 0.004 9,000 1,000

------- ----- ------- ------------- -------------

AE_3 34.9 0.09 0.022 33,000 25,000

------- ----- ------- ------------- -------------

AE_4 8.0 0.11 0.016 8,000 4,000

------- ----- ------- ------------- -------------

AE_5 11.0 0.22 0.030 24,000 11,000

------- ----- ------- ------------- -------------

AE-8 (NP) 31.3 0.19 0.008 61,000 8,000

------- ----- ------- ------------- -------------

AE-7 (LW_E) 7.7 0.14 0.025 10,000 6,000

------- ----- ------- ------------- -------------

AE-6 (LW_W) 1.3 0.13 0.011 2,000 500

------- ----- ------- ------------- -------------

Total 125.6 0.14 0.018 177,000 71,500

------- ----- ------- ------------- -------------

Note: MRE reported on oxide material only, at a cut-off grade of

0.05% copper which is consistent with the assumed In Situ Recovery

technique.

Table B: Drill Collar Locations

Hole ID EOH Depth East North RL Dip Azimuth

21AED001 156.17 763,727.91 6,256,359.35 48.69 -90(0) 360(0)

---------- ----------- ------------- ------ ------- --------

21AED002 98.85 763,908.67 6,256,599.18 48.35 -70(0) 90(0)

---------- ----------- ------------- ------ ------- --------

21AED003 93.20 763,680.15 6,256,359.62 48.39 -90(0) 360(0)

---------- ----------- ------------- ------ ------- --------

21AED004 71.95 763,849.71 6,256,442.33 46.84 -90(0) 360(0)

---------- ----------- ------------- ------ ------- --------

21AED005 96.47 763,799.52 6,256,358.84 47.91 -70(0) 90(0)

---------- ----------- ------------- ------ ------- --------

21AED006 135.4 763,988.83 6,256,682.88 44.71 -90(0) 360(0)

---------- ----------- ------------- ------ ------- --------

21AED007 115.2 763,883.93 6,256,600.85 48.09 -90(0) 360(0)

---------- ----------- ------------- ------ ------- --------

21AED008 77.8 763,739.04 6,256,274.50 47.67 -70(0) 90(0)

---------- ----------- ------------- ------ ------- --------

21AED009 32.63 763,812.14 6,256,205.90 46.10 -90(0) 360(0)

---------- ----------- ------------- ------ ------- --------

Table C: Summary of Significant Drillhole Assays (above 0.05ppm

Copper & 0.1g/t Gold)

Hole ID Drill Sample Depth From Interval Cu % Au g/t Comments

Type type (m) (m)

Full oxide

profile -

with zones

of internal

21AED001 Diam -HQ Geological 6.2 108.2 0.17 0.1 dilution

---------- ------------ ----------- --------- ----- ------- -----------------

Upper Zone

(above 0.05%

including 6.2 25.3 0.11 NSI Cu)

---------------------------------- ----------- --------- ----- ------- -----------------

Lower Zone

(above 0.05%

including 81.5 32.9 0.4 0.31 Cu)

---------------------------------- ----------- --------- ----- ------- -----------------

Lower zone

including 102 5 0.5 1.02 (above 0.05%Cu)

---------------------------------- ----------- --------- ----- ------- -----------------

Full oxide

profile (above

21AED002 Diam -HQ Geological 21.9 59.9 0.31 NSI 0.05% Cu)

---------- ------------ ----------- --------- ----- ------- -----------------

Full oxide

21AED003 Diam -HQ Geological 15 32.4 0.16 NSR profile

---------- ------------ ----------- --------- ----- ------- -----------------

including 15 13.6 0.25 NSR

---------------------------------- ----------- --------- ----- ------- -----------------

Full oxide

21AED004 Diam -HQ Geological 7 55.9 0.53 NSR profile

---------- ------------ ----------- --------- ----- ------- -----------------

Including 17.3 5.7 1.23 0.16

---------------------------------- ----------- --------- ----- ------- -----------------

Full oxide

Profile (above

21AED005 Diam -HQ Geological 6.3 72.7 1.0 0.19 0.05% Cu)

---------- ------------ ----------- --------- ----- ------- -----------------

Upper Zone

(above 0.05%

Including 15.8 18.2 2.0 0.34 Cu)

---------------------------------- ----------- --------- ----- ------- -----------------

21AED006 Diam -HQ Geological 31.1 30.8 0.09 NSR Upper Zone

---------- ------------ ----------- --------- ----- ------- -----------------

and 105.8 13 0.1 NSR Lower Zone

---------------------------------- ----------- --------- ----- ------- -----------------

Full oxide

Zone (above

21AED007 Diam -HQ Geological 33 33.6 0.14 NSR 0.05%Cu)

---------- ------------ ----------- --------- ----- ------- -----------------

Including 33 4 0.1 0.13

---------------------------------- ----------- --------- ----- ------- -----------------

Upper zone

21AED008 Diam -HQ Geological 7 7 0.13 NSR (above 0.05%Cu)

---------- ------------ ----------- --------- ----- ------- -----------------

Lower zone

and 27 15.5 0.08 (above 0.05%Cu)

---------------------------------- ----------- --------- ----- ------- -----------------

21AED009 Diam-HQ - NSR - -

------------------------ ----------- --------- ----- ------- -----------------

Notes to Table B and C

1. An accurate dip and strike and the controls on mineralisation

are only interpreted and the true width of mineralisation is

unknown at this time.

2. In Diamond (Diam drilling), individual samples were collected

at geological intervals with no individual sample smaller than 0.1m

and none larger than 1.5m.

3. All samples are analysed using a 50g fire assay with ICP-MS (inductively coupled plasma - mass spectrometry) finish gold analysis (0.01ppm detection limit) and Aqua Regia Multi-Element with ICP-MS finish (1ppm Cu detection limit) by Bureau Veritas, Adelaide South Australia.

4. Intersections are generally calculated over >1m intervals

>0.05% Cu (500ppm) using weight averaging technique. Some

internal dilution is included in 21AED001 full oxide profile

<10m below 0.05% Cu for geological ISR modelling continuity.

5. g/t (grams per tonne), ppm (parts per million), NSI = no

significant intercept above 0.01ppm Au

6. Drill type; Diam = Diamond, HQ = Diamond Core diameter

7. Coordinates are in GDA94, MGA Z53 using DGPS position

1 JORC Code, 2012 Edition - Table 1 report template

Section 1 Sampling Techniques and Data

Criteria JORC Code explanation Commentary

Sampling Diamond drilling program

techniques * Nature and quality of sampling (eg cut channels, with half core sampled

random chips, or specific specialised industry for Au fire assay FA001

standard measurement tools appropriate to the and Aqua Regia 48 element

minerals under investigation, such as down hole gamma suite AR001. Samples

sondes, or handheld XRF instruments, etc). These submitted to Bureau

examples should not be taken as limiting the broad Veritas (BV), SA. Standard

meaning of sampling. blank and duplicate

inserted every 30 samples

pXRF readings taken

* Include reference to measures taken to ensure sample very 0.5m down the hole.

representivity and the appropriate calibration of any Vanta C Series 800427

measurement tools or systems used. XRF -40sec reading time.

Instrument calibrated

externally annually

* Aspects of the determination of mineralisation that and with QA/QC at start

are Material to the Public Report. prior to sampling and

calibration disc every

30 readings

* In cases where 'industry standard' work has been done All co-ordinates are

this would be relatively simple (eg 'reverse in UTM grid (GDA94 Z53)

circulation drilling was used to obtain 1 m samples and drill hole collars

from which 3 kg was pulverised to produce a 30 g have been surveyed by

charge for fire assay'). In other cases more DGPS to an accuracy

explanation may be required, such as where there is of 0.1m. Down holes

coarse gold that has inherent sampling problems. surveys using Truman

Unusual commodities or mineralisation types (eg with readings every

submarine nodules) may warrant disclosure of detailed 6m.

information. Diamond samples were

collected at geologically

defined intervals (minimum

sample length 0.1m,

maximum sample length

1.5m) for all drill

holes in the current

program Samples are

cut using an automated

diamond saw and half

core is submitted for

analysis at Bureau

Veritas,

SA. The sample size

is deemed appropriate

for the grain size of

the material being

sampled.

Mineralisation is

determined

by descriptive geological

logs for diamond hole

as well as the

incorporation

of assay results and

pXRF readings

=================================================================

Drilling Diamond drilling - GMP

techniques * Drill type (eg core, reverse circulation, open-hole drilling Pty Ltd. B&D

hammer, rotary air blast, auger, Bangka, sonic, etc) Multi 35 Rig

and details (eg core diameter, triple or standard 0-6m open hammer -

tube, depth of diamond tails, face-sampling bit or transported

other type, whether core is oriented and if so, by cover sequence.

what method, etc). HQ standard tube diamond

drilling

====================== ================================================================= ============================

Drill sample Core recovery assessed

recovery * Method of recording and assessing core and chip and measured relative

sample recoveries and results assessed. to drill rod measurements

into laptop computer.

HQ single tube drilling

* Measures taken to maximise sample recovery and ensure through weathered zone

representative nature of the samples. to maximise sample

recovery.

The sample recovery

* Whether a relationship exists between sample recovery and condition is recorded

and grade and whether sample bias may have occurred every meter. Generally,

due to preferential loss/gain of fine/coarse core recovery is 98-100%,

material. but occasionally drops

to 70% in friable clays

zones due to compaction

and/or broken ground.

No relationship is known

to exist between sample

recovery and grade

====================== ================================================================= ============================

Logging All core is qualitative

* Whether core and chip samples have been geologically geologically logged

and geotechnically logged to a level of detail to (lithology, structure,

support appropriate Mineral Resource estimation, alteration, veining,

mining studies and metallurgical studies. mineralization weathering,

colour and other features

of the core).

* Whether logging is qualitative or quantitative in Core photography completed

nature. Core (or costean, channel, etc) photography. prior to core cutting

and after

Core (and intersections)

* The total length and percentage of the relevant logged based on

intersections logged. geological,

lithological and

structural

boundaries.

All drill samples are

measured for magnetic

susceptibility at 1m

intervals, and XRF

readings

taken every 0.5m.

====================== ================================================================= ============================

Criteria JORC Code explanation Commentary

Sub- sampling Half core samples

techniques * If core, whether cut or sawn and whether quarter, submitted

and sample half or all core taken. for laboratory analysis.

preparation Diamond core was given

up to two weeks to dry

* If non-core, whether riffled, tube sampled, rotary out, prior to cutting

split, etc and whether sampled wet or dry. and sample prep.

Sampling is carried

out using standard

For all sample types, the nature, quality protocols

and appropriateness of the sample preparation and QAQC procedures

technique. as per industry practice.

* Quality control procedures adopted for all Field QAQC procedures

sub-sampling stages to maximise representivity of involved the use of

samples. certified standards,

blanks and duplicate

sample submitted every

* Measures taken to ensure that the sampling is 25 samples. These are

representative of the in situ material collected, routinely checked against

including for instance results for field originals.

duplicate/second-half sampling. Handheld pXRF readings

reported.

pXRF readings taken

* Whether sample sizes are appropriate to the grain on whole (HQ) core at

size of the material being sampled. 0.5m intervals prior

to cutting.

Vanta Series C 40 second

reading time.

Instrument calibrated

at start, QAQC with

2 standards and 1 blank

every 30 readings.

External

instrument calibration

completed annually.

Readings taken every

0.5m down hole

=================================================================

Quality Diamond core sampled

of assay * The nature, quality and appropriateness of the through potential copper

data and assaying and laboratory procedures used and whether and gold zones.

laboratory the technique is considered partial or total. Samples submitted to

tests Bureau Veritas for 50g

fire assay and Aqua

* For geophysical tools, spectrometers, handheld XRF Regia multi-element

instruments, etc, the parameters used in determining analysis.

the analysis including instrument make and model, Internal certified

reading times, calibrations factors applied and their laboratory

derivation, etc. QAQC is undertaken

including

check samples, blanks

* Nature of quality control procedures adopted (eg and internal standards

standards, blanks, duplicates, external laboratory Handheld pXRF readings

checks) and whether acceptable levels of accuracy (ie reported.

lack of bias) and precision have been established. Vanta Series C 40 second

reading time.

Instrument calibrated

at start, QAQC with

2 standards and 1 blank

every 30 readings.

External

instrument calibration

completed annually.

Readings taken every

0.5m down hole

====================== ================================================================= ============================

Verification All drilling data is

of sampling * The verification of significant intersections by collected in a series

and assaying either independent or alternative company personnel. of templates in excel

including geological

logging, sample

* The use of twinned holes. information,

collar and survey

information,

* Documentation of primary data, data entry procedures, All data is digitally

data verification, data storage (physical and recorded in the company's

electronic) protocols. electronic database.

No adjustments have

been made to the assay

* Discuss any adjustment to assay data. data.

All significant

intersections

have been verified by

an alternative company

geologist.

There are no twinned

drillholes

====================== ================================================================= ============================

Location Collars picked up using

of data * Accuracy and quality of surveys used to locate drill DGPS - MGA94 zone 53

points holes (collar and down-hole surveys), trenches, mine (GDA) used.

workings and other locations used in Mineral Resource Down hole survey readings

estimation. taken every 6m with

Boart Longyear Truman

multi shot camera

* Specification of the grid system used.

* Quality and adequacy of topographic control.

====================== ================================================================= ============================

Data spacing Drillhole data spacing

and distribution * Data spacing for reporting of Exploration Results. is considered appropriate

to allow confident

interpretation

* Whether the data spacing and distribution is of exploration results.

sufficient to establish the degree of geological and pXRF readings taken

grade continuity appropriate for the Mineral Resource every 0.5m down the

and Ore Reserve estimation procedure(s) and hole.

classifications applied. No sample compositing

has been applied

* Whether sample compositing has been applied.

====================== ================================================================= ============================

Orientation Drill holes were oriented

of data * Whether the orientation of sampling achieves unbiased vertical (090 degrees)

in relation sampling of possible structures and the extent to or 070 towards 090degrees

to geological which this is known, considering the deposit type. which is perpendicular

structure to strike of the

geological

* If the relationship between the drilling orientation trough.

and the orientation of key mineralised structures is Orientational bias is

considered to have introduced a sampling bias, this not applicable this

should be assessed and reported if material. stage with half core

samples taken across

full mineralised zone

and pXRF sampling every

0.5m downhole

====================== ================================================================= ============================

Sample security Samples were trucked

* The measures taken to ensure sample security. from Alford to Adelaide,

to Challenger Geological

Services for cutting

and prep, prior to

submission

to Bureau Veritas,

Adelaide

for analysis.

====================== ================================================================= ============================

Audits No formal audits have

or reviews * The results of any audits or reviews of sampling been undertaken

techniques and data.

==================== ================================================================= ==============================

Section 2 Reporting of Exploration Results

Criteria JORC Code explanation Commentary

Mineral tenement Alford East project:

and land * Type, reference name/number, location and ownership * The JV area covers portions EL6255 and E6529 which

tenure status including agreements or material issues with third are 100% owned by Spencer Metals Ltd.

parties such as joint ventures, partnerships,

overriding royalties, native title interests,

historical sites, wilderness or national park and * PML 268 lies within E6529

environmental settings.

* There are no non-government royalties, historical

* The security of the tenure held at the time of sites or environmental issues.

reporting along with any known impediments to

obtaining a licence to operate in the area.

* Underlying land title is Freehold land which

extinguishes native title.

All tenure in good standing.

====================================================================

Exploration The general area of this

done by other * Acknowledgment and appraisal of exploration by other report has been explored

parties parties. in the past by various

companies including Jododex,

Uranez, North Broken

Hill, MIM, Hillgrove

Resources, Argonaut Resources

and Sandfire Resources.

Activities include AC,

RC, & Diamond drilling,

and significant geophysical

surveying. The Company

has reviewed past exploration

data generated by these

companies.

======================== ==================================================================== ============================================================

Geology Primary deposits in the

* Deposit type, geological setting and style of region are considered

mineralisation. to be of Iron Oxide Copper

Gold (IOCG) affinity,

related to the 1590Ma

Hiltaba/GRV event. Cu-Au-Mo-Pb

mineralisation is structurally

controlled and associated

with significant metasomatic

alteration and deep weathering

or kaolinisation of host

rocks.

Locally, the low-grade

copper/gold oxide mineralisation

that forms the basis

for this Exploration

results announcement,

is hosted within variably

weathered and sheared

metasedimentary basement

lithologies.

======================== ==================================================================== ============================================================

Drill hole Drillhole information

Information * A summary of all information material to the is included in report,

understanding of the exploration results including a with Table B summarising

tabulation of the following information for all drillhole collar information.

Material drill holes: Plan and sections showing

drillhole locations is

included in report

o easting and northing of the drill hole

collar

o elevation or RL (Reduced Level - elevation

above sea level in metres) of the drill

hole collar

o dip and azimuth of the hole

o down hole length and interception depth

o hole length.

* If the exclusion of this information is justified on

the basis that the information is not Material and

this exclusion does not detract from the

understanding of the report, the Competent Person

should clearly explain why this is the case.

======================== ==================================================================== ============================================================

Data aggregation Weighted averaging technique

methods * In reporting Exploration Results, weighting averaging is used for reporting

techniques, maximum and/or minimum grade truncations exploration assay results,

(eg cutting of high grades) and cut-off grades are with pXRF Intersections

usually Material and should be stated. are calculated by simple

averaging of 0.5m assays.

No metal equivalents

* Where aggregate intercepts incorporate short lengths are reported.

of high-grade results and longer lengths of low-grade

results, the procedure used for such aggregation

should be stated and some typical examples of such

aggregations should be shown in detail.

* The assumptions used for any reporting of metal

equivalent

values should be clearly stated

======================== ==================================================================== ============================================================

Criteria JORC Code explanation Commentary

Relationship The copper oxide mineralization

between mineralisation * These relationships are particularly important in the is associated with intense

widths and reporting of Exploration Results. clay alteration. The

intercept alteration is interpreted

lengths to be similar to that

* If the geometry of the mineralisation with respect to found in the adjacent

the drill hole angle is known, its nature should be Alford West area.

reported. The drilling intersections

quoted are downhole

intercept lengths with

* If it is not known and only the down hole lengths are an unknown orientation

reported, there should be a clear statement to this to dip and plunge of

effect (eg 'down hole length, true width not known'). the target mineralisation

====================================================================

Diagrams Appropriate maps and

* Appropriate maps and sections (with scales) and sections included in

tabulations of intercepts should be included for any document.

significant discovery being reported These should

include, but not be limited to a plan view of drill

hole collar locations and appropriate sectional

views.

========================== ==================================================================== ============================================================

Balanced reporting All results have been

* Where comprehensive reporting of all Exploration reported

Results is not practicable, representative reporting

of both low and high grades and/or widths should be

practiced to avoid misleading reporting of

Exploration Results.

========================== ==================================================================== ============================================================

Other substantive All data have been reported

exploration * Other exploration data, if meaningful and material,

data should be reported including (but not limited to):

geological observations; geophysical survey results;

geochemical survey results; bulk samples - size and

method of treatment; metallurgical test results; bulk

density, groundwater, geotechnical and rock

characteristics; potential deleterious or

contaminating substances.

========================== ==================================================================== ============================================================

Further work Awaiting additional

* The nature and scale of planned further work (eg laboratory assays.

tests for lateral extensions or depth extensions or Drilling to continue

large-scale step- out drilling). along sections and areas

open to the north and

south.

* Diagrams clearly highlighting the areas of possible Refer to diagram in

extensions, including the main geological document for geological

interpretations and future drilling areas, provided interpretation and potential

this information is not commercially sensitive. extensions.

========================== ==================================================================== ============================================================

This information is provided by RNS, the news service of the

London Stock Exchange. RNS is approved by the Financial Conduct

Authority to act as a Primary Information Provider in the United

Kingdom. Terms and conditions relating to the use and distribution

of this information may apply. For further information, please

contact rns@lseg.com or visit www.rns.com.

RNS may use your IP address to confirm compliance with the terms

and conditions, to analyse how you engage with the information

contained in this communication, and to share such analysis on an

anonymised basis with others as part of our commercial services.

For further information about how RNS and the London Stock Exchange

use the personal data you provide us, please see our Privacy

Policy.

END

DRLFFLLLLLLEBBF

(END) Dow Jones Newswires

February 22, 2022 02:00 ET (07:00 GMT)

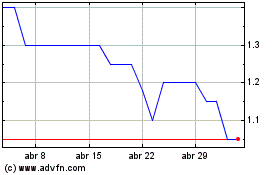

Thor Energy (LSE:THR)

Gráfica de Acción Histórica

De Mar 2024 a Abr 2024

Thor Energy (LSE:THR)

Gráfica de Acción Histórica

De Abr 2023 a Abr 2024