Acceleware Ltd. (“Acceleware” or the “Company”) (TSX-V: AXE), a

leading innovator of transformative technologies targeting the

decarbonization of industrial heating, is pleased to announce that

it has been awarded Phase 2 of a potash ore drying project by the

International Minerals Innovation Institute (IMII). The new project

phase will advance Phase 1 work and is intended to further validate

the use of radio frequency (RF) energy from Acceleware’s Clean Tech

Inverter (CTI) to dry potash ore and other minerals. IMII is a

non-profit organization jointly funded by industry and government

that is committed to developing and implementing innovative

education, training, research and development partnerships for

supporting a world-class minerals industry. IMII’s minerals

industry members include BHP, Cameco Corporation, Fission Uranium

Corp., The Mosaic Company and Nutrien Ltd..

Following a successful IMII Exploring

Innovations Program project, which validated the potential for RF

energy from the CTI to dry potash ore, Acceleware was invited to

submit a subsequent proposal for additional project work. Phase 2

development includes the design, construction, and testing of

prototype CTI-powered dryers at increasing scale. Objectives

include validating the effectiveness of the technology and

optimizing the dryer design. Subsequent phases will focus on

increasing the scale of the systems to support commercial

production levels. The initial stage of Phase 2 includes the

construction and testing of a 100 kilogram per hour drying system,

and the final stage involves the development and testing of a

larger (maximum 5 tonnes per hour) dryer upon successful completion

of the 100 kilogram per hour tests. The overall project is intended

to confirm that RF energy from the CTI can effectively and

efficiently dry potash ore.

Acceleware’s CTI drying platform is expected to

lower operating costs while significantly reducing greenhouse gas

(GHG) emissions levels. Upon successful completion of Phase 2, IMII

may continue development into Phase 3, which could include

construction and testing of a small commercial scale dryer with a

30 tonne per hour capacity. A subsequent Phase 4 could include the

construction and testing of a full commercial scale dryer with a

capacity of up to 130 tonnes per hour.

Published reports put the industrial dryer

market at US$3.5 billion in 2022, growing to US$4.7 billion in

20261. Acceleware’s analysis of the dryer market for the mining

sector indicates a US$1 billion opportunity for low emissions

dryers over the next 10 years.

“The Acceleware team is excited to get to work

on the next phase of this project, which will essentially prove out

the concept of CTI electrification to decarbonize the drying of

potash ore and other mineral commodities at large-scale,” said

Geoff Clark, Chief Executive Officer of Acceleware. “We believe

that we have cracked the code, so to speak, for the use of

solid-state electromagnetic energy for industrial scale heating and

drying applications and are looking forward to demonstrating the

many benefits resulting from this game-changing decarbonization

project. The CTI could make significant GHG emissions reductions,

alongside economic benefits for the mining industry. We look

forward to next steps and are specifically pleased to be working

with IMII and its world-class potash members.”

“As a member of IMII, we are pleased to support

Phase 2 of the pilot. Achieving net zero scope 1 emissions is one

of the largest decarbonization challenges for conventional potash

producers. The CTI technology being developed has the potential to

play an exciting role in decarbonizing potash processing and could

provide a pathway to reduced scope 1 emissions,” said Kathlene

Jacobson, Principal Innovation, BHP. Added Al Shpyth, IMII’s

executive director, “A CTI commercial-scale drying platform with

lower operating costs could present an opportunity for a

sustainability win for the minerals industry, reducing energy and

improving economics, while lowering GHGs. As the minerals industry

shifts focus to innovative solutions for a lower environmental

footprint, we see economic benefits and sustainability going

hand-in-hand in many instances and are actively seeking out those

opportunities.”

Acceleware’s patented CTI is unique in its

ability to economically decarbonize industrial heating applications

even at very large scale. A commercial scale drying platform for

mining will augment Acceleware’s portfolio of decarbonization

applications. Currently, Acceleware is in final phases of testing

at its commercial scale pilot for electrification of heavy oil

production via RF XL, the first of several industrial heating

applications that Acceleware is commercializing.

Additional work is underway at Acceleware for

decarbonization of other heavy emitting industrial heating

applications that will play a critical role in a successful energy

transition, including agricultural drying and the production of

hydrogen via methane pyrolysis.

About IMIIIMII is a non-profit organization

jointly funded by industry and government and is committed to

developing and implementing innovative education, training,

research and development partnerships for supporting a world-class

minerals industry.

IMII serves as an Innovation Steward to strengthen the

Saskatchewan minerals industry’s competitiveness and growth through

Research, Development & Demonstration and Education &

Training to drive the future’s Qualified & Representative

Workforce.

About AccelewareAcceleware is

an advanced electromagnetic (EM) heating company with highly

scalable EM solutions for large industrial applications. The

Company’s solutions provide an opportunity to economically

electrify and decarbonize industrial heating processes previously

considered difficult to abate, which could have a significant

impact on global GHG emissions.

Acceleware is piloting RF XL, its patented

low-cost, low-carbon EM thermal production technology for heavy oil

and oil sands that is materially different from any heavy oil

recovery technique used today. The Company is also working with a

consortium of world-class potash partners on a pilot project using

its patented and field proven Clean Tech Inverter (CTI) to

decarbonize drying of potash ore and other minerals. Acceleware is

actively developing partnerships for EM heating of other industrial

applications in mining, steel, agriculture, cement, hydrogen and

other clean fuels.

Acceleware and Saa Dene Group (co-founded by Jim

Boucher) have created Acceleware | Kisâstwêw to raise the profile,

adoption, and value of Acceleware technologies. The partnership is

intended to improve the environmental and economic performance of

industry by supporting ideals that are important to Indigenous

peoples, including respect for land, water, and clean air.

Acceleware is a public company listed on

Canada’s TSX Venture Exchange under the trading symbol “AXE”.

Disclaimers

This news release contains “forward-looking

information” and “forward-looking statements” (collectively,

“forward-looking statements”) within the meaning of the applicable

Canadian securities legislation. All statements, other than

statements of historical fact, are forward-looking statements and

are based on expectations, estimates and projections as at the date

of this release. Any statement that involves discussions with

respect to predictions, expectations, beliefs, plans, projections,

objectives, assumptions, future events or performance (often but

not always using phrases such as “expects”, “anticipates”, “plans”,

“continues”, “budget”, “scheduled”, “forecasts”, “estimates”,

“believes” or “intends” or variations or negatives of such words

and phrases or stating that certain actions, events or results

“may” or “could”, “would”, “might”, “shall” or “will” be taken to

occur or be achieved) are not statements of historical fact and may

be forward-looking statements.

In this news release, forward-looking statements

relate to, among other things, statements relating to the benefits

of CTI electrification, future development plans and timing,

prospective applicability of CTI drying to mining and other

industries, application and market potential of CTI, and market

size. Various assumptions or factors are typically applied in

drawing conclusions or making the forecasts or projections set out

in forward-looking information. Those assumptions and factors are

based on information currently available to the Company. The

material facts and assumptions include initial studies of

applicability of CTI technology to mining applications are

accurate, third party estimates of market size are correct, and the

timeline estimates are reasonable. Actual results may vary from the

forward-looking information in this news release due to certain

material risk factors. The Company cautions the reader that the

above list of risk factors is not exhaustive and additional risk

factors risk factors are described in detail in Acceleware’s

continuous disclosure documents, which are filed on SEDAR at

www.sedar.com. The forward-looking information contained in this

release is made as of the date hereof and the Company is not

obligated to update or revise any forward-looking information,

whether as a result of new information, future events or otherwise,

except as required by applicable securities laws. Due to the risks,

uncertainties and assumptions contained herein, investors should

not place undue reliance on forward-looking information. The

foregoing statements expressly qualify any forward-looking

information contained herein.

Neither the TSXV nor its Regulation

Services Provider (as that term is defined in the policies of the

TSXV) accepts responsibility for the adequacy or accuracy of this

release.

For further information:Geoff Clark, CEOTel:

+1-403-249-9099geoff.clark@acceleware.com

Acceleware Ltd.435 10th Avenue SECalgary, AB,

T2G 0W3 CanadaTel: +1-403-249-9099www.acceleware.com

1 Valuates Reports: “Global Industrial Driers Market Research

Report 2023”

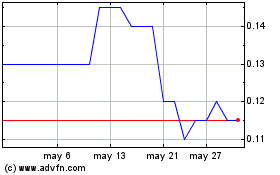

Acceleware (TSXV:AXE)

Gráfica de Acción Histórica

De Nov 2024 a Dic 2024

Acceleware (TSXV:AXE)

Gráfica de Acción Histórica

De Dic 2023 a Dic 2024