TIDMALL

RNS Number : 4104W

Atlantic Lithium Limited

12 December 2023

12 December 2023

Maiden Feldspar Mineral Resource Estimate

15.7Mt at 40.2% Feldspar

Ewoyaa Lithium Project, Ghana

Maiden MRE reported for feldspar at Ewoyaa, intended to be

supplied to the local Ghanaian ceramics industry and expected to

further enhance the Project's economics

Atlantic Lithium Limited (AIM: ALL, ASX: A11, OTCQX: ALLIF,

"Atlantic Lithium" or the "Company"), the African-focused lithium

exploration and development company targeting to deliver Ghana's

first lithium mine, is pleased to announce a maiden JORC (2012)

compliant Mineral Resource Estimate of 15.7Mt at 40.2% feldspar

("Feldspar MRE") for the Company's flagship Ewoyaa Lithium Project

("Ewoyaa Project" or the "Project") in Ghana, West Africa.

Highlights

- Maiden 15.7Mt at 40.2% Feldspar Mineral Resource Estimate

reported for the Ewoyaa Lithium Project, including 13.7Mt (87%) in

the Measured and Indicated categories.

- The Feldspar MRE is confined to the Ewoyaa Main, Ewoyaa

Northeast, Ewoyaa South-1 and Ewoyaa South-2 deposits, which

constitute approximately the first five years of planned spodumene

concentrate production at the Project, as indicated by the Ewoyaa

Definitive Feasibility Study ("DFS", refer announcement of 29 June

2023 ).

- The Feldspar MRE is based on the same geological model that

resulted in the 35.3Mt at 1.25% Li(2) O MRE(1) for the Project

("MRE" or "Resource"; refer announcement of 1 February 2023 ) and

includes 31.1% quartz and 11.7% muscovite, as additional potential

by-products of spodumene concentrate production at Ewoyaa.

- Maiden Feldspar MRE enables the potential inclusion of

feldspar by-product credits in future revisions of the Ewoyaa

feasibility studies, believed to drive down operating costs and

further enhance the value of the Project.

- Feldspar is widely used in the ceramics industry; the Company

believes Ewoyaa could become a major producer of domestic feldspar

in Ghana, which Atlantic Lithium intends to supply into the local

Ghanaian ceramics market.

- Metallurgical test work and ceramic application trials

undertaken; ceramic trials successfully produced acceptable,

industry-standard ware, comparable in all aspects, including

contraction, water absorption, density, porosity, shape, colour and

appearance.

- Further Feldspar MRE growth targeted through the inclusion of

analysis of historic drilling samples across remaining pegmatite

deposits and new drilling currently underway.

- Maiden Feldspar MRE will be incorporated into the ongoing

Feldspar Definitive Feasibility Study ("Feldspar Study") being

undertaken to assess the viability and prospective market

conditions for the production of feldspar at Ewoyaa (refer

announcement of 15 August 2023 ); with results due in Q1 2024.

Commenting, Neil Herbert, Executive Chairman of Atlantic

Lithium, said :

" Identified early on by the Company as a by-product of

spodumene concentrate production at Ewoyaa, the definition of the

maiden Feldspar MRE now confirms the Project's potential as a major

source of domestic feldspar in Ghana, capable of delivering

industry-standard saleable ware.

"Currently supplied only by small-scale mining operations, we

intend to supply the feldspar into the local Ghanian ceramics

market. The Feldspar MRE indicates Ewoyaa's potential to meet and

even surpass Ghana's demand requirements, further demonstrating the

significant contribution the Project is expected to bring to

Ghana.

"The Feldspar MRE is based on the same geological model that

delivered the 35.3Mt MRE for the Project, as announced in February

2023, and incorporates approximately the first five years mine

schedule, as outlined in the DFS. With 87% of the resource in the

higher confidence Measured and Indicated categories, the Feldspar

MRE represents a further significant de-risking and potentially

value-enhancing milestone for the Project as we move closer towards

construction.

"Currently, the economic outcomes indicated by the Definitive

Feasibility Study for the Project do not consider the production of

feldspar at Ewoyaa. The definition of the Feldspar MRE, therefore,

enables the inclusion of feldspar by-product credits in future

revisions of the Project's economics, offering the potential to

further enhance the already impressive financial outcomes expected

to be delivered at Ewoyaa.

" With only the first approximate five years of planned lithium

production included in the Feldspar MRE, there is significant

potential to further grow the resource. The Feldspar MRE will then

be incorporated into the ongoing Feldspar Study which is evaluating

the prospective market conditions and viability of producing

feldspar at the Project. Results of the Feldspar Study are expected

in Q1 2024.

"Initial feldspar quality test work has delivered good quality

vitreous hotelware, high-end earthenware and floor tiles and

successfully substituted industry accepted feldspar in trial

firings. The results of the trials are very encouraging for the

manufacture of saleable feldspar products.

"We look forward to delivering the results of the Feldspar Study

in Q1 2024 and, later in the year, a revised feldspar resource

estimate considering the life of the mine. These represent,

respectively, just two of the major milestones in our sights in

2024 before we break ground at Ewoyaa. "

Maiden Feldspar Mineral Resource Estimate

The Company reports a maiden Mineral Resource Estimate of 15.7Mt

at 40.2% feldspar ("Feldspar MRE") confined to the Ewoyaa Main,

Ewoyaa Northeast, Ewoyaa South-1 and Ewoyaa South-2 deposits, which

represent approximately the first five years of planned production

from the Ewoyaa Lithium Project, as detailed in the Ewoyaa

Definitive Feasibility Study ("DFS") (refer announcement of 29 June

2023 ).

The Feldspar MRE is based on the same geological model that

resulted in the 35.3Mt @ 1.25% Li(2) O Mineral Resource Estimate(1)

for the Project ("MRE" or "Resource"), as announced by the Company

on 1 February 2023.

The Feldspar MRE will be incorporated into the feldspar

Definitive Feasibility Study ("Feldspar Study"), undertaken by the

Company to investigate the economic impact of producing additional

feldspar by-products from the mining of lithium ore at the Project

(refer announcement of 15 August 2023 ).

The Feldspar MRE includes a total of 3.5Mt at 39.7% feldspar in

the Measured category, 10.2Mt at 40.5% feldspar in the Indicated

category and 2Mt at 40.1% feldspar in the Inferred category. In

addition to the feldspar, further by-products of quartz and

muscovite were estimated and included (refer Table 1 ).

The independent Feldspar MRE was completed by Ashmore Advisory

Pty Ltd ("Ashmore") of Perth, Western Australia, with results

tabulated in the Statement of Mineral Resources in Table 1. The

Statement of Mineral Resources is reported in line with

requirements of the JORC Code (2012) and is therefore suitable for

public reporting.

To undertake the estimation, the Company engaged Telemark

Geosciences Ltd ("Telemark") to conduct normative mineralogy

calculations on pegmatite samples obtained from historic drilling

within the Resource area, in addition to new drilling undertaken

and reported to date from the 2023 drilling programme.

The Ewoyaa pegmatites, which make up the Project's deposits,

contain relatively consistent amounts of spodumene (within the

mineralised zones), quartz, albite, potassic feldspar

("k-feldspar") and muscovite mica, along with numerous accessory

minerals in relatively minor amounts. Normative mineralogy was

calculated from total fusion X-ray fluorescence ("XRF") major

element data using a least squares method. The normative

calculations were validated against and corrected where necessary

using X-ray diffraction ("XRD") Reitveld semi-quantitative

mineralogical data from 65 sample pulps selected to represent a

range of chemical compositions and mineralogy.

High-level Whittle optimisation, completed by Mining Focus

Consultants Pty Ltd of Perth, Western Australia, demonstrates

reasonable prospects for eventual economic extraction on the basis

of the lithium Project (refer announcement of 29 June 2023 ).

Table 1: Ewoyaa Lithium Project Feldspar Mineral Resource

Estimate (0.5% Li(2) O Cut-off)

Measured Mineral Resource

Deposit Tonnage Feldspar Quartz Muscovite

Mt % Mt % Mt % Mt

------------- --------- ----- ------- ----- ----- -------

Ewoyaa Main 3.5 39.7 1.37 31.8 1.10 11.5 0.40

--------- -----

Total 3.5* 39.7 1.37 31.8 1.10 11.5 0.40

------------- --------- ----- ------- ----- -----

Indicated Mineral Resource

---------------------------------------------------------------

Deposit Tonnage Feldspar Quartz Muscovite

Mt % Mt % Mt % Mt

------------- --------- ----- ------- ----- ----- -------

Ewoyaa Main 6.5 40.8 2.66 31.6 2.06 11.9 0.78

Ewoyaa Northeast 3.1 39.4 1.23 29.6 0.93 11.1 0.35

Ewoyaa South 1 0.4 42.1 0.16 29.3 0.11 11.7 0.04

Ewoyaa South 2 0.2 41.9 0.07 25.2 0.04 13.0 0.02

------------- --------- ----- ------- ----- ----- -------

Total 10.2* 40.5 4.13 30.8 3.14 11.7 1.19

------------- --------- ----- ------- ----- ----- -------

Inferred Mineral Resource

---------------------------------------------------------------

Deposit Tonnage Feldspar Quartz Muscovite

Mt % Mt % Mt % Mt

------------- --------- ----- ------- ----- ----- -------

Ewoyaa Main 0.6 41.8 0.23 30.6 0.17 11.5 0.06

Ewoyaa Northeast 0.4 39.5 0.15 30.5 0.11 13.0 0.05

Ewoyaa South 1 0.4 40.4 0.16 32.6 0.13 12.8 0.05

Ewoyaa South 2 0.7 38.8 0.27 31.7 0.22 12.6 0.09

--------- -----

Total 2.0* 40.1 0.81 31.4 0.63 12.4 0.25

------------- --------- ----- ------- ----- -----

Total Mineral Resource

Deposit Tonnage Feldspar Quartz Muscovite

Mt % Mt % Mt % Mt

------------- --------- ----- ------- ----- ----- -------

Ewoyaa Main 10.5 40.5 4.27 31.6 3.33 11.7 1.24

Ewoyaa Northeast 3.5 39.4 1.38 29.7 1.04 11.3 0.40

Ewoyaa South 1 0.8 41.3 0.32 31.0 0.24 12.2 0.09

Ewoyaa South 2 0.9 39.4 0.35 30.4 0.27 12.7 0.11

Total 15.7* 40.2 6.31 31.1 4.87 11.7 1.84

------------- --------- ----- ------- ----- -----

NOTE: Based on the lithium Mineral Resource Estimate(1) reported

for the Project in February 2023 and confined to the Ewoyaa Main,

Ewoyaa Northeast, Ewoyaa South-1 and Ewoyaa South-2 deposits. Total

tonnage figures do not include tonnage of spodumene as indicated in

the February 2023 Mineral Resource Estimate(1) for the Project, nor

minor accessory minerals.

The Feldspar MRE has been compiled under the supervision of Mr.

Shaun Searle who is a director of Ashmore Advisory Pty Ltd and a

Registered Member of the Australian Institute of Geoscientists. Mr.

Searle has sufficient experience that is relevant to the style of

mineralisation and type of deposit under consideration and to the

activity that he has undertaken to qualify as a Competent Person as

defined in the JORC Code and a Qualified Person under the AIM Rules

for Companies. Mr Searle consents to the inclusion of the

information in relation to the Mineral Resource in the form and

context in which it appears.

All Mineral Resources figures reported in the table above

represent estimates at December 2023. Mineral Resource estimates

are not precise calculations, being dependent on the interpretation

of limited information on the location, shape and continuity of the

occurrence and on the available sampling results. The totals

contained in the above table have been rounded to reflect the

relative uncertainty of the estimate. Rounding may cause some

computational discrepancies.

Mineral Resources are reported in accordance with the

Australasian Code for Reporting of Exploration Results, Mineral

Resources and Ore Reserves (The Joint Ore Reserves Committee Code -

JORC 2012 Edition).

Feldspar quality and its intended use is impacted by weathering;

with fresh 'Primary' feldspar used for higher specification

applications, as opposed to transition 'Weathered' material. Their

estimated relative abundances, and concentrate grades are shown in

Table 2.

To show the tonnage and grade distribution throughout the entire

deposit, a bench breakdown has been prepared using a 10m bench

height, shown in Figure 1, with a grade-tonnage curve for the

classified resource shown in Figure 2.

Table 2: Material types, recoveries and concentrate grades

(recoveries based on laboratory results)

Measured Mineral Resource

-------- ---------------------------------------------------------------------

Type Tonnage Feldspar Quartz Muscovite

Mt % Mt % Mt % Mt

-------- --------------------------- ----- ------- ----- ---------- -----

Primary 3.5 39.7 1.37 31.8 1.10 11.5 0.40

-------- ------- ----------

Total 3.5* 39.7 1.37 31.8 1.10 11.5 0.40

-------- --------------------------- ----- ------- ----- ----------

Indicated Mineral Resource

-------- ---------------------------------------------------------------------

Type Tonnage Feldspar Quartz Muscovite

Mt % Mt % Mt % Mt

-------- --------------------------- ----- ------- ----- ---------- -----

Weathered 0.5 37.1 0.17 33.9 0.15 11.2 0.05

Primary 9.8 40.6 3.96 30.6 2.99 11.7 1.14

-------- ------- ----------

Total 10.2* 40.5 4.13 30.8 3.14 11.7 1.19

-------- --------------------------- ----- ------- ----- ----------

Inferred Mineral Resource

-------- ---------------------------------------------------------------------

Type Tonnage Feldspar Quartz Muscovite

Mt % Mt % Mt % Mt

-------- --------------------------- ----- ------- ----- ---------- -----

Weathered 0.6 37.7 0.22 31.1 0.18 11.9 0.07

Primary 1.4 41.0 0.59 31.4 0.45 12.6 0.18

-------- ------- ----------

Total 2.0* 40.1 0.81 31.4 0.63 12.4 0.25

-------- --------------------------- ----- ------- ----- ----------

Total Mineral Resource

-------- ---------------------------------------------------------------------

Type Tonnage Feldspar Quartz Muscovite

Mt % Mt % Mt % Mt

-------- --------------------------- ----- ------- ----- ---------- -----

Weathered 1.0 37.4 0.38 32.3 0.33 11.6 0.12

Primary 14.7 40.4 5.93 31.0 4.54 11.7 1.72

-------- ------- ----------

Total 15.7* 40.2 6.31 31.1 4.87 11.7 1.84

-------- --------------------------- ----- ------- ----- ----------

NOTE: As per Table 1 above and in Competent Persons section at

end of document.

Total tonnage figures do not include tonnage of spodumene as

indicated in the February 2023 Mineral Resource Estimate(1) for the

Project, nor minor accessory minerals.

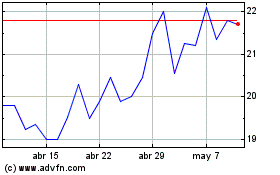

Figure 1: Ewoyaa bench tonnage - 10m bench elevation

Figure 2: Ewoyaa feldspar grade - tonnage curve for classified

pegmatite resource

A plan view of the deposit areas is shown in Figure 3, with a

long section shown in Figure 4 and cross-section within the Ewoyaa

Main indicated category zone shown in Figure 5.

Figure 3: Plan View of Ewoyaa Feldspar MRE wireframes and

drilling with prospect names

Figure 4: Long Section Z-Z' of Ewoyaa Main wireframes and

drilling (View towards 300deg; solid colours = Resource(1)

wireframes, wireframe edges = pegmatite wireframes)

Figure 5: Cross Section A-A' of Ewoyaa Block Model feldspar

grades and drilling (with downhole lithium grade along drill hole

trace)

The Feldspar MRE is based on a 0.5% reporting cut-off grade

within a 0.4% Li(2) O wireframed pegmatite body. However, when

assessing all pegmatite volumes (with no cut-offs applied), there

is significant scope to increase the resource tonnage.

Table 3 below shows the overall resource tonnage and grade for

the Ewoyaa Main, Ewoyaa Northeast, Ewoyaa South-1 and Ewoyaa

South-2 deposits, inclusive of all pegmatite material. For example,

the resource can be reported at a significantly larger tonnage by

reducing the cut-off grade to 0.2% Li(2) O, giving an increased

resource of 20.8Mt at 41.6% feldspar. However, as feldspar is

primarily a by-product of the lithium mining operation, the mine

plan will be tailored towards maximising lithium recovery.

Further studies will assess the potential benefits of increased

production by reducing the cut-off grade or higher feed grade on

overall Project economics, consistent with market price predictions

and price trends realised by existing producers.

The Company will conduct further sodium assay analysis and

normative mineralogical calculations for the remaining historic and

current drill campaigns outside the Ewoyaa Main, Ewoyaa Northeast,

Ewoyaa South-1 and Ewoyaa South-2 deposits, with the aim of

increasing the current Feldspar MRE.

Table 3: Overall resource tonnage and grade for the deposit,

inclusive all pegmatite material

Geology and Geological Interpretation

The Ewoyaa Lithium Project area lies within the Birimian

Supergroup, a Proterozoic volcano-sedimentary basin located in

Western Ghana. The Project area is underlain by three forms of

metamorphosed schist; mica schist, staurolite schist and garnet

schist. Several granitoids intrude the basin metasediments as small

plugs. These granitoids range in composition from intermediate

granodiorite (often medium-grained) to felsic leucogranites (coarse

to pegmatoidal grain size), sometimes in close association with

pegmatite veins and bodies.

Pegmatite intrusions generally occur as sub-vertical dykes with

two dominant trends: either east-southeast (Ewoyaa Northeast)

dipping sub-vertically northeast; or north-northeast (Ewoyaa Main)

dipping sub-vertically to moderately to the east. Pegmatite

thickness varies across the Project, with thinner mineralised units

intersected at Ewoyaa Northeast and Ewoyaa South-2 between 10m and

20m; and thicker units intersected at Ewoyaa Main between 30 and

60m, and up to 100m at surface.

Drill Methods

The database contains data for the auger, reverse circulation

("RC") and diamond core ("DD") drilling conducted by the Company

since 2018. The drilling was completed by the Company in six

phases, commencing in April 2018. All the drilling was undertaken

by GeoDrill (Ghana), using both RC and DD rigs.

Drilling at the deposit extends to a vertical depth of

approximately 319m and the mineralisation was modelled from surface

to a depth of approximately 330m below surface. The Feldspar MRE is

based on good quality RC and DD drilling data. Drill hole spacing

is predominantly 20m by 20m and 40m by 40m in the well-drilled

portions of the Project and up to 80m by 80m to 100m by 100m across

the breadth of the known mineralisation.

The RC drilling used a combination of 5.25' and 5.75' face

sampling hammers. The DD used PQ and HQ (85mm and 63.5mm) diameter

core barrels. The DD holes were completed from surface or as tails

with PQ to maximise recovery in weathered zones, with reversion to

HQ once ground conditions improved within fresh material.

In 2018, Phase 1 RC holes were completed on a nominal 100m by

50m grid pattern, targeting the Ewoyaa Main mineralised system.

Phases 2 to 5 reduced the wide spacing to 80m by 40m and down to

40m by 40m in the well drilled portions of the Project. Phase 5 was

a major infill drilling program down to 40m by 40m over most of the

Project. Phase 6 included extensional drilling in areas of open

mineralisation, as well as close spaced infill drilling in portions

of the Ewoyaa deposit.

During Phase 1 and 2, RC drilling bulk samples and splits were

collected at the rig for every metre interval drilled, the splits

being undertaken using a riffle splitter. During Phase 3, Phase 4,

Phase 5 and Phase 6, RC samples were split with a rig mounted cone

spitter, which took duplicate samples for quality control

purposes.

DD was cut with a core saw and selected half core samples was

dispatched to Nagrom Laboratory in Australia for metallurgical test

work.

Selected core intervals were cut to quarter core with a saw at

one-metre intervals or to geological contacts; and since December

2018, were sent to Intertek Laboratory in Tarkwa, Ghana for sample

preparation. Prior to that, samples were sent to SGS Laboratory in

Tarkwa for sample preparation.

All Phase 1 samples were submitted to SGS Tarkwa for preparation

(PRP100) and subsequently forwarded to SGS Johannesburg and later

SGS Vancouver for analysis (ICP90A).

PRP100 - Samples <3kg are dried in trays, crush to 100%

passing 2mm, split using a rotary splitter to 5kg and pulverised in

a LM2 to a nominal 85% passing 75um. Approximately 100g sub-sample

is taken for assay. All the preparation equipment is flushed with

barren material prior to the commencement of the job. Coarse reject

material was kept in the original bag.

Since December 2018, samples have been submitted to Intertek

Tarkwa (SP02/SP12) for sample preparation. Samples were weighed,

dried and crushed to -2mm in a Boyd crusher with an 800-1,200g

rotary split, producing a nominal 1,500g split crushed sample,

which was subsequently pulverised in a LM2 ring mill. Samples were

pulverised to a nominal 85% passing 75um. All the preparation

equipment was flushed with barren material prior to the

commencement of the job. Coarse reject material was kept in the

original bag. Lab sizing analysis was undertaken on a nominal 1:25

basis. Final pulverised samples (20g) were airfreighted to Intertek

in Perth, Australia for assaying.

Sample Analysis Method

Since December 2018, samples were sent to Intertek Laboratory in

Perth for analysis (FP6/MS/OES). FP6/MS/OES is an analysis for

lithium and a suite of 21 other elements. Detection limits for

lithium range between 5ppm and 20,000ppm. The sodium peroxide

fusion (in nickel crucibles) is completed with hydrochloric acid to

dissolve the sub-sample and is considered a total dissolution.

Analysis is conducted by Inductively Coupled Plasma Mass

Spectrometry ("ICP-MS").

Prior to December 2018, Phase 1 samples were submitted to SGS

Johannesburg and later SGS Vancouver for analysis (ICP90A). ICP90

is a 28-element combination Na2O2 fusion with ICP-OES. ICP-MS was

added to some submissions for additional trace element

characterisation purposes.

All phase 1 SGS pulps were subsequently sent to Intertek

Laboratory Perth for re-analysis (FP6/MS/OES) and included in the

resource estimate.

During 2023, 8,793 pulps from the first four drilling campaigns

were analysed for Na using four-acid digestion. The majority of

these pulps were analysed as 2m composites of the original 1m

interval pulps. These re-assayed pulps formed the basis for

normative mineralogy calculations by Telemark.

Quality Control

Quality control data for major elements important for normative

mineral calculations (Al, Si, K, Ca, Na, Li) were quantitatively

reviewed to evaluate the accuracy and precision of the geochemical

data. Data were taken from three client-inserted certified

reference materials (CRM) produced by AMIS (AMIS0682, AMIS0683,

AMIS0684) using a mix of sodium peroxide fusion and fusion XRF

analyses completed by Intertek, Perth. Sodium data were added for

selected samples in 2023 using a 4-acid digestion to allow for

normative mineral estimation.

The three CRMs used were produced from material from the Ewoyaa

lithium deposit and so are ideally matrix-matched for the

mineralisation. In addition, field, coarse crush (preparation) and

pulp duplicate data have been assessed to constrain the relative

precision of the data using the average coefficient of variation

("CVAVG").

A total of 678 granodiorite blanks with low Li content (<50

ppm) were submitted with the drill samples and the major element

data have also been assessed for possible cross contamination.

Normative Mineralogy and Mineralogical Model Validation

Normative mineralogy for samples contained within the Project

has been calculated using a least-squares minimisation technique

called MINSQ. The method requires major and trace element data, as

well as a mineralogical model appropriate to the samples. MINSQ

calculates a normative mineralogy for each sample that minimises

the differences between the observed geochemistry and the predicted

geochemistry for a given mineralogy. The purpose of the analysis is

to estimate the amount of by-product quartz, feldspar and muscovite

available from the mining of spodumene in mineralised

pegmatites.

Minerals having overlapping compositions such as potassium

feldspar and muscovite which are common in pegmatites require

quantitative mineralogical data to determine whether a consistent

ratio between different minerals having similar compositions can be

applied to the data. A total of 65 samples were analysed by

semi-quantitative XRD at Microanalysis Australia, Mount Lawley,

Western Australia using a normalised reference intensity ratio

method and used to validate model predictions from MINSQ.

Two mineralogical models were utilised based on whether the

material was fresh or transitional to oxide material with the

mineral kaolinite incorporated into the latter model as a

replacement for anorthite. Minerals rarely identified in the XRD

analyses, or which occur at low concentration and thus have low

confidence in their identification, were excluded from the

mineralogical model. Therefore, all lithium in the samples reports

to the dominant lithium phase spodumene.

As a general observation, the visual agreement between the

normative mineralogy and geochemistry is better in the fresh

samples compared to transitional samples. This reflects the

complexity added to the mineralogy by partially weathered samples,

although overall the difference in deviation from the mean between

samples within transitional and fresh is small, suggesting that the

mineral models used are producing similar results for both material

types.

Mineral Resource Classification Criteria

The Ewoyaa Lithium Project deposits show good continuity of the

main mineralised units which allowed the drill hole intersections

to be modelled into coherent, geologically robust domains.

Consistency is evident in the thickness of the structure, and the

distribution of grade appears to be reasonable along and across

strike.

The Feldspar MRE was classified as a Measured, Indicated and

Inferred Mineral Resource based on data quality, sample spacing,

and lode continuity. The Measured Mineral Resource was defined

within areas of close spaced RC and DD drilling of less than 20m by

20m, and where the continuity and predictability of the lode

positions was good. Indicated Mineral Resource was defined within

areas of close spaced RC and DD drilling of less than 40m by 40m,

and where the continuity and predictability of the lode positions

was good.

In addition, Indicated Mineral Resource was confined to the

fresh rock. The Inferred Mineral Resource was assigned to

transitional material, areas where drill hole spacing was greater

than 40m by 40m, where small, isolated pods of mineralisation occur

outside the main mineralised zones, and to geologically complex

zones.

Estimation Methodology

A Surpac block model was created to encompass the extents of the

known mineralisation. The block model was rotated on a bearing of

30deg, with block dimensions of 10m NS by 10m EW by 5m vertical

with sub-cells of 2.5m by 2.5m by 1.25m. The block size was

selected based on results of Kriging Neighbourhood Analysis ("KNA")

and also in consideration of two predominant mineralisation

orientations of 30deg and 100 to 120deg.

The parent block size was selected based on KNA, while

dimensions in other directions were selected to provide sufficient

resolution to the block model in the across-strike and down-dip

direction.

Bulk densities ranging between 1.7t/m(3) and 2.78t/m(3) were

assigned in the block model dependent on lithology, mineralisation

and weathering. These densities were applied based on 13,901 bulk

density measurements conducted by the Company on 101 DD holes and

35 RC holes with diamond tails conducted across the breadth of the

Project. The measurements were separated using weathering surfaces,

geology and mineralisation solids, with averages assigned in the

block model.

Cut-off Grade

The Statement of Mineral Resources has been constrained by the

mineralisation solids and reported above a cut-off grade of 0.5%

Li(2) O. The reporting cut-off grade is supported by a high-level

Whittle optimisation.

Mining and Metallurgical Methods and Parameters

The Statement of Mineral Resources has been constrained by the

mineralisation solids, reported at a cut-off grade of 0.5% Li(2) O.

Whittle optimisations demonstrate reasonable prospects for eventual

economic extraction.

Based on the Ewoyaa DFS (refer announcement of 29 June 2023 ),

the Company could produce approximately 500,000 to 1,000,000 tonnes

per annum of mixed potassium oxide (K(2) O) / sodium oxide (Na(2)

O) feldspar as a by-product from spodumene concentrate to be sold

for lithium purification. Initial test work assessed the quality of

two size fractions derived from dense media separation ("DMS"); 2.6

SG oversize fraction with high total alkalis ("O/F") and 2.6 SG

undersize fraction with lower alkalis ("U/F") but significant Li(2)

O at approximately 0.70%, which is a strong flux.

Following examination of chemical and mineralogical composition,

ceramic application trials were undertaken in Stoke-on-Trent (The

Potteries) for vitreous hotelware, high-end earthenware and floor

tiles. Samples were wet ground to the required particle size and

incorporated into commercial recipes, substituting for standard

feldspars and nepheline syenite. Each prepared body was factory

fired and, in the case of vitreous hotelware and high-end

earthenware, biscuit (not glazed), glazed and decorated pieces were

produced.

In all cases, the trial firings produced acceptable ware,

comparable to industry standards in all aspects, including

contraction, water absorption, density, porosity, shape, colour and

appearance. Good results were delivered at the vitreous hotelware

factory (a world leading manufacturer of tableware for the

international hospitality industry), where the Ewoyaa feldspars

were substituted for Forshammer feldspar (produced in Sweden by

Sibelco) (refer Figure 6 ).

Further geological, geotechnical, engineering and metallurgical

studies are recommended to further define the feldspar

mineralisation and marketable products.

Figure 6: Trial-fired ceramic plates and bowls, manufactured in

biscuit (unglazed), glazed and decorated forms (left to right),

comprising of trial standard, O/F sample and U/F sample (top to

bottom). The trials, which deemed that no visual differences were

detected between the trial standard and sample plates, successfully

produced industry-accepted standard of ware across all aspects.

JORC Table 1, Section 1 (Sampling Techniques and Data) and

Section 2 (Reporting of Exploration Results) are included in

Appendix 1.

JORC Table 1, Section 3 (Estimation and Reporting of Mineral

Resources) is included in Appendix 2.

End Notes

(1) Ore Reserves, Mineral Resources and Production Targets

The information in this announcement that relates to Ore

Reserves, Mineral Resources and Production Targets complies with

the 2012 Edition of the Australasian Code for Reporting of

Exploration Results, Mineral Resources and Ore Reserves (JORC

Code). The information in this announcement relating to the Mineral

Resource Estimate ("MRE") of 35.3Mt @ 1.25% Li(2) O for Ewoyaa is

extracted from the Company's announcement dated 1 February 2023,

which is available at atlanticlithium.com.au . The MRE includes a

total of 3.5Mt @ 1.37% Li(2) O in the Measured category, 24.5Mt @

1.25% Li(2) O in the Indicated category and 7.4Mt @ 1.16% Li(2) O

in the Inferred category. The Company confirms that all technical

parameters underpinning the MRE continue to apply. Material

assumptions for the Project have been revised on grant of the

Mining Lease for the Project, announced by the Company on 20

October 2023. The Company is not aware of any new information or

data that materially affects the information included in this

announcement or the announcements dated 1 February 2023 and 20

October 2023.

Competent Persons

Information in this report relating to the exploration results

is based on data reviewed by Mr Lennard Kolff (MEcon. Geol., BSc.

Hons ARSM), Chief Geologist of the Company. Mr Kolff is a Member of

the Australian Institute of Geoscientists who has in excess of 20

years' experience in mineral exploration and is a Qualified Person

under the AIM Rules. Mr Kolff consents to the inclusion of the

information in the form and context in which it appears.

Information in this report relating to Mineral Resources was

compiled by Shaun Searle, a Member of the Australian Institute of

Geoscientists. Mr Searle has sufficient experience that is relevant

to the style of mineralisation and type of deposit under

consideration and to the activity being undertaken to qualify as a

Competent Person as defined in the 2012 Edition of the

'Australasian Code for Reporting of Exploration Results, Mineral

Resources and Ore Reserves'. Mr Searle is a director of Ashmore.

Ashmore and the Competent Person are independent of the Company and

other than being paid fees for services in compiling this report,

neither has any financial interest (direct or contingent) in the

Company.

This announcement contains inside information for the purposes

of Article 7 of the Market Abuse Regulation (EU) 596/2014 as it

forms part of UK domestic law by virtue of the European Union

(Withdrawal) Act 2018 ("MAR"), and is disclosed in accordance with

the Company's obligations under Article 17 of MAR.

For any further information, please contact:

Atlantic Lithium Limited

Neil Herbert (Executive Chairman)

Amanda Harsas (Finance Director and Company Secretary)

www.atlanticlithium.com.au

IR@atlanticlithium.com.au

Tel: +61 2 8072 0640

SP Angel Corporate Finance Yellow Jersey PR Limited Canaccord Genuity Limited

LLP Charles Goodwin Financial Adviser:

Nominated Adviser Bessie Elliot Raj Khatri (UK) /

Jeff Keating atlantic@yellowjerseypr.com Duncan St John, Christian

Charlie Bouverat Tel: +44 (0)20 3004 Calabrese (Australia)

Tel: +44 (0)20 3470 9512

0470 Corporate Broking:

James Asensio

Tel: +44 (0) 20 7523

4500

============================== ============================= =============================

Notes to Editors:

About Atlantic Lithium

www.atlanticlithium.com.au

Atlantic Lithium is an AIM and ASX-listed lithium company

advancing a portfolio of lithium projects in Ghana and Côte

d'Ivoire through to production.

The Company's flagship project, the Ewoyaa Project in Ghana, is

a significant lithium spodumene pegmatite discovery on track to

become Ghana's first lithium-producing mine.

The Definitive Feasibility Study for the Project indicates the

production of 3.6Mt of spodumene concentrate over a 12-year mine

life, making it one of the top 10 largest spodumene concentrate

mines in the world.

The Project, which was awarded a Mining Lease in October 2023,

is being developed under a funding agreement with Piedmont Lithium

Inc.

Atlantic Lithium holds 509km(2) and 774km(2) of tenure across

Ghana and Côte d'Ivoire respectively, comprising significantly

under-explored, highly prospective licences.

APPIX 1 - JORC Code (2012) Table 1, Sections 1 and 2

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections).

Criteria JORC Code Explanation Commentary

============ =========================================================== ===========================================================

Sampling

techniques * Nature and quality of sampling (eg cut channels, * RC drill holes were routinely sampled at 1m intervals

random chips, or specific specialised industry with a nominal 3-6kg sub-sample split off for assay

standard measurement tools appropriate to the using a rig-mounted cone splitter at 1m intervals.

minerals under investigation, such as down hole gamma

sondes, or handheld XRF instruments, etc). These

examples should not be taken as limiting the broad * DD holes were quarter core sampled at 1m intervals or

meaning of sampling. to geological contacts for geochemical analysis.

* Include reference to measures taken to ensure sample * For assaying, splits from all prospective ore zones

representivity and the appropriate calibration of any (i.e. logged pegmatites +/- interburden) were sent

measurement tools or systems used. for assay. Outside of these zones, the splits were

composited to 4m using a portable riffle splitter.

* Aspects of the determination of mineralisation that

are Material to the Public Report. In cases where * Holes without pegmatite were not assayed.

'industry standard' work has been done this would be

relatively simple (eg 'reverse circulation drilling

was used to obtain 1 m samples from which 3 kg was * Approximately 5% of all samples submitted were

pulverised to produce a 30 g charge for fire assay'). standards and coarse blanks. Blanks were typically

In other cases more explanation may be required, such inserted with the interpreted ore zones after the

as where there is coarse gold that has inherent drilling was completed.

sampling problems. Unusual commodities or

mineralisation types (eg submarine nodules) may

warrant disclosure of detailed information. * Approximately 2.5% of samples submitted were

duplicate samples collected after logging using a

riffle splitter and sent to an umpire laboratory.

This ensured zones of interest were duplicated and

not missed during alternative routine splitting of

the primary sample.

* Prior to the December 2018 - SGS Tarkwa was used for

sample preparation (PRP100) and subsequently

forwarded to SGS Johannesburg for analysis; and later

SGS Vancouver for analysis (ICP90A).

* Post December 2018 to present - Intertek Tarkwa was

used for sample preparation (SP02/SP12) and

subsequently forwarded to Intertek Perth for analysis

(FP6/MS/OES - 21 element combination Na(2) O(2)

fusion with combination OES/MS).

* ALS Laboratory in Brisbane was used for the Company's

initial due diligence work programs and was selected

as the umpire laboratory since Phase 1. ALS conducts

ME-ICP89, with a Sodium Peroxide Fusion. Detection

limits for lithium are 0.01-10%. Sodium Peroxide

fusion is considered a "total" assay technique for

lithium. In addition, 22 additional elements assayed

with Na(2) O(2) fusion, and combination MS/ICP

analysis.

* During 2023, 8,793 pulps from the first four drilling

campaigns were analysed for Na using four-acid

digestion. The majority of these pulps were analysed

as 2m composites of the original 1m interval pulps.

============ =========================================================== ===========================================================

Drilling

techniques * Drill type (eg core, reverse circulation, open-hole * Six phases of drilling were undertaken at the Project

hammer, rotary air blast, auger, Bangka, sonic, etc) using RC and DD techniques. All the RC drilling used

and details (eg core diameter, triple or standard face sampling hammers.

tube, depth of diamond tails, face-sampling bit or

other type, whether core is oriented and if so, by

what method, etc). * Phase 1 and 2 programs used a 5.25 inch hammers while

Phase 3 used a 5.75-inch hammer. Phase 5 and 6

programmes used 5.5 inch hammer for RC and diamond

pre-collar drilling.

* All DD holes were completed using PQ and HQ core from

surface (85mm and 63.5mm).

* All DD holes were drilled in conjunction with a

Reflex ACT II tool; to provide an accurate

determination of the bottom-of-hole orientation.

* All fresh core was orientated to allow for geological

,

structural and geotechnical logging by a Company

geologist.

------------ ----------------------------------------------------------- -----------------------------------------------------------

Drill sample

recovery * Method of recording and assessing core and chip * A semi-quantitative estimate of sample recovery was

sample recoveries and results assessed. completed for the vast majority of drilling. This

involved weighing both the bulk samples and splits

and calculating theoretical recoveries using assumed

* Measures taken to maximise sample recovery and ensure densities. Where samples were not weighed,

representative nature of the samples. qualitative descriptions of the sample size were

recorded. Some sample loss was recorded in the

collaring of the RC drill holes.

* Whether a relationship exists between sample recovery

and grade and whether sample bias may have occurred

due to preferential loss/gain of fine/coarse * DD recoveries were measured and recorded. Recoveries

material. in excess of 95.8% have been achieved for the DD

drilling program. Drill sample recovery and quality

is adequate for the drilling technique employed.

* The DD twin program has identified a positive grade

bias for lithium in the DD compared to the RC

results.

============ =========================================================== ===========================================================

Logging

* Whether core and chip samples have been geologically * All drill sample intervals were geologically logged

and geotechnically logged to a level of detail to by Company geologists.

support appropriate Mineral Resource estimation,

mining studies and metallurgical studies.

* Where appropriate, geological logging recorded the

abundance of specific minerals, rock types and

* Whether logging is qualitative or quantitative in weathering using a standardised logging system that

nature. Core (or costean, channel, etc) photography. captured preliminary metallurgical domains.

* The total length and percentage of the relevant * All logging is qualitative, except for the systematic

intersections logged. collection of magnetic susceptibility data which

could be considered semi quantitative.

* Strip logs have been generated for each drill hole to

cross-check geochemical data with geological logging.

* A small sample of washed RC drill material was

retained in chip trays for future reference and

validation of geological logging, and sample reject

materials from the laboratory are stored at the

Company's field office.

* All drill holes have been logged and reviewed by

Company technical staff.

* The logging is of sufficient detail to support the

current reporting of a Mineral Resource.

============ =========================================================== ===========================================================

Sub-sampling

techniques * If core, whether cut or sawn and whether quarter, * RC samples were cone split at the drill rig. For

and sample half or all core taken. interpreted waste zones the 1 or 2m rig splits were

preparation later composited using a riffle splitter into 4m

composite samples.

--

* If non-core, whether riffled, tube sampled, rotary

split, etc and whether sampled wet or dry. * DD core was cut with a core saw and selected half

core samples totalling 427.1kg dispatched to Nagrom

Laboratory in Perth for preliminary metallurgical

* For all sample types, the nature, quality and test work.

appropriateness of the sample preparation technique.

* The other half of the core, including the

* Quality control procedures adopted for all bottom-of-hole orientation line, was retained for

sub-sampling stages to maximise representivity of geological reference.

samples.

* The remaining DD core was quarter cored for

* Measures taken to ensure that the sampling is geochemical analysis.

representative of the in situ material collected,

including for instance results for field

duplicate/second-half sampling. * Since December 2018, samples were submitted to

Intertek Tarkwa (SP02/SP12) for sample preparation.

Samples were weighed, dried and crushed to -2mm in a

* Whether sample sizes are appropriate to the grain Boyd crusher with an 800-1,200g rotary split,

size of the material being sampled. producing a nominal 1,500g split crushed sample;

which was subsequently pulverised in a LM2 ring mill.

Samples were pulverised to a nominal 85% passing

75um. All the preparation equipment was flushed with

barren material prior to the commencement of the job.

Coarse reject material was kept in the original bag.

Lab sizing analysis was undertaken on a nominal 1:25

basis. Final pulverised samples (20g) were

airfreighted to Intertek in Perth for assaying.

* The vast majority of samples were drilled dry.

Moisture content was logged qualitatively. All

intersections of the water table were recorded in the

database.

* Field sample duplicates were taken to evaluate

whether samples were representative and understand

repeatability, with good repeatability.

* Sample sizes and laboratory preparation techniques

were appropriate and industry standard.

------------ ----------------------------------------------------------- -----------------------------------------------------------

Quality of

assay data * The nature, quality and appropriateness of the * Analysis for lithium and a suite of other elements

and assaying and laboratory procedures used and whether for Phase 1 drilling was undertaken at SGS

laboratory the technique is considered partial or total. Johannesburg / Vancouver by ICP-OES after Sodium

tests Peroxide Fusion. Detection limits for lithium (10ppm

- 100,000ppm). Sodium Peroxide fusion is considered a

* For geophysical tools, spectrometers, handheld XRF "total" assay technique for lithium.

instruments, etc, the parameters used in determining

the analysis including instrument make and model,

reading times, calibrations factors applied and their * During 2023, 8,793 pulps from the first four drilling

derivation, etc. campaigns were analysed for Na using four-acid

digestion at Intertek laboratory, Perth. The majority

of these pulps were analysed as 2m composites of the

* Nature of quality control procedures adopted (eg original 1m interval lithium pulps.

standards, blanks, duplicates, external laboratory

checks) and whether acceptable levels of accuracy (ie

lack of bias) and precision have been established. * Review of standards and blanks from the initial

submission to Johannesburg identified failures

(multiple standards reporting outside control

limits). A decision was made to resubmit this batch

and all subsequent batches to SGS Vancouver - a

laboratory considered to have more experience with

this method of analysis and sample type.

* Results of analyses for field sample duplicates are

consistent with the style of mineralisation and

considered to be representative. Internal laboratory

QAQC checks are reported by the laboratory, including

sizing analysis to monitor preparation and internal

laboratory QA/QC. These were reviewed and retained in

the company drill hole database.

* 155 samples were sent to an umpire laboratory (ALS)

and/assayed using equivalent techniques, with results

demonstrating good repeatability.

* Atlantic Lithium's review of QAQC suggests the SGS

Vancouver and Intertek Perth laboratories performed

within acceptable limits.

* No geophysical methods or hand-held XRF units have

been used for determination of grades in the Mineral

Resource.

============ =========================================================== ===========================================================

Verification

of sampling * The verification of significant intersections by * Significant intersections were visually field

and assaying either independent or alternative company personnel. verified by company geologists and Shaun Searle of

Ashmore during the 2019 site visit.

* The use of twinned holes.

* Drill hole data was compiled and digitally captured

by Company geologists in the field. Where

* Documentation of primary data, data entry procedures, hand-written information was recorded, all hardcopy

data verification, data storage (physical and records were kept and archived after digitising.

electronic) protocols.

* Phase 1 and 2 drilling programs were captured on

* Discuss any adjustment to assay data. paper or locked excel templates and migrated to an MS

Access database and then into Datashed (industry

standard drill hole database management software).

Since the Phase 3 drilling program data was captured

using LogChief which has inbuilt data validation

protocols. All analytical results were transferred

digitally and loaded into the database by a Datashed

consultant.

* The data was audited, and any discrepancies checked

by the Company personnel before being updated in the

database.

* Twin DD holes were drilled to verify results of the

RC drilling programs. Results indicate a positive

bias towards the DD method when compared to RC

drilling for Li(2) O, and it was shown that there is

severe iron contamination in the RC drilling process.

* Reported drill hole intercepts were compiled by the

Chief Geologist.

* Adjustments to the original assay data included

converting Li ppm to Li(2) O%.

------------ ----------------------------------------------------------- -----------------------------------------------------------

Location of

data points * Accuracy and quality of surveys used to locate drill * The collar locations were surveyed in WGS84 Zone 30

holes (collar and down-hole surveys), trenches, mine North using DGPS survey equipment, which is accurate

workings and other locations used in Mineral Resource to 0.11mm in both horizontal and vertical directions.

estimation. All holes were surveyed by qualified surveyors. Once

validated, the survey data was uploaded into

Datashed. For the current resource upgrade, HHGPS

* Specification of the grid system used. collar positions were used.

* Quality and adequacy of topographic control. * RC drill holes were routinely down hole surveyed

every 6m using a combination of EZ TRAC 1.5 (single

shot) and Reflex Gyroscopic tools.

* After the tenth drill hole, the survey method was

changed to Reflex Gyro survey with 6m down hole data

points measured during an end-of-hole survey.

* All Phase 2 and 3 drill holes were surveyed initially

using the Reflex Gyro tool, but later using the more

efficient Reflex SPRINT tool.

* All Phase 4 and 5 drill holes were surveyed with a

Reflex SPRINT tool.

* LiDAR survey completed by Southern Mapping to produce

rectified colour images and a digital terrain model

(DTM) over 32km(2)

* C206 Aircraft - mounted LiDAR Riegl Q780 Camera

Hasselblad H5Dc with 50mm Fixfocus lens.

* Coordinate system: WGS84 UTM30N with accuracy to

+/-0.04

* The topographic survey and photo mosaic output from

the survey is accurate to 20mm.

* Locational accuracy at collar and down the drill hole

is considered appropriate for resource estimation

purposes.

============ =========================================================== ===========================================================

Data spacing

and * Data spacing for reporting of Exploration Results. * The RC holes were initially drilled on 100m spaced

distribution sections and 50m hole spacings orientated at 300deg

or 330deg with dips ranging from -50deg to -60deg.

* Whether the data spacing, and distribution is Planned hole orientations/dips were occasionally

sufficient to establish the degree of geological and adjusted due to pad and/or access constraints.

grade continuity appropriate for the Mineral Resource

and Ore Reserve estimation procedure(s) and

classifications applied. * For Phase 2 and 3 programs, hole spacing was reduced

to 80m spaced sections and 40m hole spacings

orientated at 300deg or 310deg, while the Abonko,

* Whether sample compositing has been applied. Kaampakrom and Ewoyaa NE trends were drilled at

220deg, with dips of -50deg.

* Samples were composited to 1m and 2m intervals prior

to estimation.

------------ ----------------------------------------------------------- -----------------------------------------------------------

Orientation

of data in * Whether the orientation of sampling achieves unbiased * The drill line and drill hole orientation are

relation to sampling of possible structures and the extent to oriented as close as practicable to perpendicular to

geological which this is known, considering the deposit type. the orientation of the general mineralised

structure orientation.

* If the relationship between the drilling orientation

and the orientation of key mineralised structures is * Most of the drilling intersects the mineralisation at

considered to have introduced a sampling bias, this close to 90 degrees ensuring intersections are

should be assessed and reported if material. representative of true widths. It is possible that

new geological interpretations and/or infill drilling

requirements may result in changes to drill

orientations on future programs.

* No orientation-based sampling bias has been

identified in the data.

============ =========================================================== ===========================================================

Sample

security * The measures taken to ensure sample security. * Samples were stored on site prior to road

transportation by Company personnel to the SGS

preparation laboratory.

* With the change of laboratory to Intertek, samples

were picked up by the contractor and transported to

the sample preparation facility in Takoradi.

* For the Na analysis, stored pulps were retrieved from

secure container storage at the project field site

for compositing, re-packing and delivery to Intertek.

------------ ----------------------------------------------------------- -----------------------------------------------------------

Audits or

reviews * The results of any audits or reviews of sampling * Prior to the drilling program, a third-party Project

techniques and data. review was completed by an independent consultant

experienced with the style of mineralisation.

* In addition, Shaun Searle of Ashmore reviewed

drilling and sampling procedures during the 2019 site

visit and found that all procedures and practices

conform to industry standards.

============ =========================================================== ===========================================================

Section 2 Reporting of Exploration Results

Criteria JORC Code Explanation Commentary

============== ====================================================================== ===========================================================

Mineral

tenement and * Type, reference name/number, location and ownership * The Project covers two contiguous licences, the

land tenure including agreements or material issues with third Mankessim (RL 3/55) and Mankessim South (PL3/109)

status parties such as joint ventures, partnerships, licence.

overriding royalties, native title interests,

historical sites, wilderness or national park and

environmental settings. * The Mankessim licence is a joint-venture, with the

licence in the name of the joint-venture party

(Barari DV Ghana Limited). Document number:

* The security of the tenure held at the time of 0853652-18.

reporting along with any known impediments to

obtaining a license to operate in the area.

* The Project occurs within a Mineral Prospecting

licence and was renewed on the 27 July 2021 for a

further three-year period, valid until 27 July 2024.

* The Mankessim South licence is a wholly-owned

subsidiary of Green Metals Resources. The Mineral

Prospecting licence renewal was submitted in Nov 2022

for a further three-year period.

* The tenement is in good standing with no known

impediments.

* Mining Lease granted in respect of the Project for a

period of 15 years, effective 20 October 2023 until

19 October 2038, file number ML 3/239.

-------------- ---------------------------------------------------------------------- -----------------------------------------------------------

Exploration

done by other * Acknowledgment and appraisal of exploration by other * Historical trenching and mapping were completed by

parties parties. the Ghana Geological survey during the 1960s. But for

some poorly referenced historical maps, none of the

technical data from this work was located. Many of

the historical trenches were located, cleaned and

re-logged. No historical drilling was completed.

-------------- ---------------------------------------------------------------------- -----------------------------------------------------------

Geology

* Deposit type, geological setting and style of * Pegmatite-hosted lithium deposits are the target for

mineralisation. exploration. This style of mineralisation typically

forms as dykes and sills intruding or in proximity to

granite source rocks.

* Surface geology within the Project area typically

consists of sequences of staurolite and

garnet-bearing pelitic schist and granite with lesser

pegmatite and mafic intrusives. Outcrops are

typically sparse and confined to ridge tops with

colluvium and mottled laterite blanketing much of the

undulating terrain making geological mapping

challenging. The hills are often separated by broad,

sandy drainages.

* The Ewoyaa pegmatites contain relatively consistent

amounts of spodumene (within the mineralised zones),

quartz, albite, potassic feldspar ("k-feldspar") and

muscovite mica, along with numerous other minerals in

relatively minor amounts.

-------------- ---------------------------------------------------------------------- -----------------------------------------------------------

Drill hole

information * A summary of all information material to the * Exploration results are not being reported.

under-standing of the exploration results including a

tabulation of the following information for all

Material drill holes: * All information has been included in the appendices.

No drill hole information has been excluded.

* easting and northing of the drill hole collar

* elevation or RL (Reduced Level - elevation above sea

level in metres) of the drill hole collar

* dip and azimuth of the hole

* down hole length and interception depth

* hole length

* If the exclusion of this information is justified on

the basis that the information is not Material and

this exclusion does not detract from the

understanding of the report, the Competent Person

should clearly explain why this is the case.

-------------- ---------------------------------------------------------------------- -----------------------------------------------------------

Data

aggregation * In reporting Exploration Results, weighting averaging * Exploration results are not being reported.

methods techniques, maximum and/or minimum grade truncations

(e.g. cutting of high grades) and cut-off grades are

usually Material and should be stated. * Not applicable as a Mineral Resource is being

reported.

* Where aggregate intercepts incorporate short lengths

of high grade results and longer lengths of low grade * No metal equivalent values are being reported.

results, the procedure used for such aggregation

should be stated and some typical examples of such

aggregations should be shown in detail.

* The assumptions used for any reporting of metal

equivalent values should be clearly stated.

============== ====================================================================== ===========================================================

Relationship

between * These relationships are particularly important in the * The drill line and drill hole orientation are

mineralisation reporting of Exploration Results. oriented as close to 90 degrees to the orientation of

widths and the anticipated mineralised orientation as

intercept practicable.

lengths * If the geometry of the mineralisation with respect to

the drill hole angle is known, its nature should be

reported. * The majority of the drilling intersects the

mineralisation between 60 and 80 degrees.

* If it is not known and only the down hole lengths are

reported, there should be a clear statement to this

effect (e.g. 'down hole length, true width not

known').

============== ====================================================================== ===========================================================

Diagrams

* Appropriate maps and sections (with scales) and * Relevant diagrams have been included within the

tabulations of intercepts should be included for any Mineral Resource report main body of text.

significant discovery being reported. These should

include, but not be limited to a plan view of drill

hole collar locations and appropriate sectional

views.

============== ====================================================================== ===========================================================

Balanced

Reporting * Accuracy and quality of surveys used to locate drill * All hole collars were surveyed WGS84 Zone 30 North

holes (collar and down-hole surveys), trenches, mine grid using a differential GPS. All RC and DD holes

workings and other locations used in Mineral Resource were down-hole surveyed with a north-seeking

estimation. gyroscopic tool.

* Where comprehensive reporting of all Exploration * Exploration results are not being reported.

Results is not practicable, representative reporting

of both low and high grades and/or widths should be

practiced to avoid misleading reporting of

Exploration Results.

-------------- ---------------------------------------------------------------------- -----------------------------------------------------------

Other

substantive * Other exploration data, if meaningful and material, * Results were estimated from drill hole assay data,

exploration should be reported including (but not limited to): with geological logging used to aid interpretation of

data geological observations; geophysical survey results; mineralised contact positions.

geochemical survey results; bulk samples - size and

method of treatment; metallurgical test results; bulk

density, groundwater, geotechnical and rock * Geological observations are included in the report.

characteristics; potential deleterious or

contaminating substances.

============== ====================================================================== ===========================================================

Further work

* The nature and scale of planned further work (e.g. * Follow up RC and DD drilling will be undertaken.

tests for lateral extensions or depth extensions or

large- scale step-out drilling).

* Further metallurgical test work may be required as

the Project progresses through the study stages.

* Diagrams clearly highlighting the areas of possible

extensions, including the main geological

interpretations and future drilling areas, provided * Drill spacing is currently considered adequate for

this information is not commercially sensitive. the current level of interrogation of the Project.

-------------- ---------------------------------------------------------------------- -----------------------------------------------------------

APPIX 2 - JORC Code (2012) Table 1, Section 3

Section 3 Estimation and Reporting of Mineral Resources

Criteria JORC Code Explanation Commentary

============== =========================================================== ===========================================================

Database

integrity * Measures taken to ensure that data has not been * The database has been systematically audited by

corrupted by, for example, transcription or keying Atlantic Lithium geologists.

errors, between its initial collection and its use

for Mineral Resource estimation purposes.

* All drilling data has been verified as part of a

continuous validation procedure. Once a drill hole is

* Data validation procedures used. imported into the database a report of the collar,

down-hole survey, geology, and assay data are

produced. This is then checked by an Atlantic Lithium

geologist and any corrections are completed by the

database manager.

-------------- ----------------------------------------------------------- -----------------------------------------------------------

Site visits

* Comment on any site visits undertaken by the * A site visit was conducted by Shaun Searle of Ashmore

Competent Person and the outcome of those visits. during February 2019. Shaun inspected the deposit

area, drill core/chips and outcrop. During this time,

notes and photos were taken. Discussions were held

* If no site visits have been undertaken indicate why with site personnel regarding drilling and sampling

this is the case. procedures. No major issues were encountered.

-------------- ----------------------------------------------------------- -----------------------------------------------------------

Geological

interpretation * Confidence in (or conversely, the uncertainty of) the * The confidence in the geological interpretation is

geological interpretation of the mineral deposit. considered to be good and is based on visual

confirmation in outcrop and within drill hole

intersections.

* Nature of the data used and of any assumptions made.

* Geochemistry and geological logging have been used to

* The effect, if any, of alternative interpretations on assist identification of lithology and

Mineral Resource estimation. mineralisation.

* The use of geology in guiding and controlling Mineral * The Project area lies within the Birimian Supergroup,

Resource estimation. a Proterozoic volcano-sedimentary basin located in

Western Ghana. The Project area is underlain by three

forms of metamorphosed schist; mica schist,

* The factors affecting continuity both of grade and staurolite schist and garnet schist. Several

geology. granitoids intrude the basin metasediments as small

plugs. These granitoids range in composition from

intermediate granodiorite (often medium grained) to

felsic leucogranites (coarse to pegmatoidal grain

size), sometimes in close association with pegmatite

veins and bodies. Pegmatite intrusions generally

occur as sub-vertical dykes with two dominant trends:

either east-northeast or north-northeast and dip

sub-vertically to moderately southeast to

east-southeast. Thickness varies across the Project,

with thinner mineralised units intersected at Abonko

and Kaampakrom between 4 to 12m; and thicker units

intersected at Ewoyaa Main between 30 to 60m And up

to 100m at surface.

* Infill drilling has supported and refined the model

and the current interpretation is considered robust.

* Observations from the outcrop of mineralisation and

host rocks; as well as infill drilling, confirm the

geometry of the mineralisation.

* Infill drilling has confirmed geological and grade

continuity.

-------------- ----------------------------------------------------------- -----------------------------------------------------------

Dimensions

* The extent and variability of the Mineral Resource * The Project Mineral Resource area extends over a

expressed as length (along strike or otherwise), plan north-south strike length of 4,390m (from 577,380mN -

width, and depth below surface to the upper and lower 581,770mN), and includes the 360m vertical interval

limits of the Mineral Resource. from 80mRL to -280mRL.

-------------- ----------------------------------------------------------- -----------------------------------------------------------

Estimation and

modelling * The nature and appropriateness of the estimation * Using parameters derived from modelled variograms,

techniques technique(s) applied and key assumptions, including Ordinary Kriging ("OK") was used to estimate average

treatment of extreme grade values, domaining, block grades in three passes using Surpac software.

interpolation parameters and maximum distance of Linear grade estimation was deemed suitable for the

extrapolation from data points. If a computer Cape Coast Mineral Resource due to the geological

assisted estimation method was chosen include a control on mineralisation. The extrapolation of the

description of computer software and parameters used. lodes along strike and down-dip has been limited to a

distance of 40m. Zones of extrapolation are

classified as Inferred Mineral Resource.

* The availability of check estimates, previous

estimates and/or mine production records and whether

the Mineral Resource estimate takes appropriate * It is assumed that there are no by-products or

account of such data. deleterious elements as shown by metallurgical test

work.

* The assumptions made regarding recovery of

by-products. * The Li(2) O (%), Fe (%), K (%), Al (%), Mn (%), Na

(%) and Ti (ppm) grades; as well as spodumene (%),

quartz (%), albite (%), k-feldspar (%) and muscovite

* Estimation of deleterious elements or other non-grade (%) mineral contents were interpolated into the

variables of economic significance (eg sulphur for Surpac block model.

acid mine drainage characterisation).

* A Surpac block model was created to encompass the

* In the case of block model interpolation, the block extents of the known mineralisation. The block model

size in relation to the average sample spacing and was rotated on a bearing of 30deg, with block

the search employed. dimensions of 10m NS by 10m EW by 5m vertical with

sub-cells of 2.5m by 2.5m by 1.25m. The parent block

size dimension was selected on the results obtained

* Any assumptions behind modelling of selective mining from Kriging Neighbourhood Analysis and also in

units. consideration of two predominant mineralisation

orientations of 30deg and 100 to 120deg.

* Any assumptions about correlation between variables.

* An orientated 'ellipsoid' search was used to select

data and adjusted to account for the variations in

* Description of how the geological interpretation was lode orientations, however all other parameters were

used to control the resource estimates. taken from the variography derived from Domains 1, 2,

3, 4, 7 and 8. Up to three passes were used for each

domain. First pass had a range of 50m, with a minimum

* Discussion of basis for using or not using grade of 8 samples. For the second pass, the range was

cutting or capping. extended to 100m, with a minimum of 4 samples. For

the third pass, the range was extended to 200m, with

a minimum of 1 or 2 samples. A maximum of 16 samples

* The process of validation, the checking process used, was used for each pass with a maximum of 4 samples

the comparison of model data to drill hole data, and per hole.

use of reconciliation data if available.

* No assumptions were made on selective mining units.

* Correlation analysis was conducted on the domains at

Ewoyaa Main.

* The mineralisation was constrained by pegmatite

geology wireframes and internal lithium bearing

mineralisation wireframes prepared using a nominal

0.4% Li(2) O cut-off grade and a minimum down-hole

length of 3m. The wireframes were used as hard

boundaries for the interpolation.

* Statistical analysis was carried out on data from 87

mineralised domains. Following a review of the

population histograms and log probability plots and

noting the low coefficient of variation statistics,

it was determined that the application of high-grade

cuts was not warranted.

* Validation of the model included detailed visual

validation, comparison of composite grades and block

grades by strike panel and elevation. Validation

plots showed good correlation between the composite

grades and the block model grades.

-------------- ----------------------------------------------------------- -----------------------------------------------------------

Moisture

* Whether the tonnages are estimated on a dry basis or * Tonnages and grades were estimated on a dry in situ

with natural moisture, and the method of basis.

determination of the moisture content.

-------------- ----------------------------------------------------------- -----------------------------------------------------------

Cut-off

parameters * The basis of the adopted cut-off grade(s) or quality * The Statement of Mineral Resources has been

parameters applied. constrained by the mineralisation solids and reported

a cut-off grade of 0.5% Li(2) O. Whittle

optimisations demonstrate reasonable prospects for

eventual economic extraction.

-------------- ----------------------------------------------------------- -----------------------------------------------------------

Mining factors

or assumptions * Assumptions made regarding possible mining methods, * Ashmore has assumed that the deposit could be mined

minimum mining dimensions and internal (or, if using open pit mining techniques. A high-level

applicable, external) mining dilution. It is always Whittle optimisation of the Mineral Resource supports

necessary as part of the process of determining this view.

reasonable prospects for eventual economic extraction

to consider potential mining methods, but the

assumptions made regarding mining methods and

parameters when estimating Mineral Resources may not

always be rigorous. Where this is the case, this

should be reported with an explanation of the basis

of the mining assumptions made.